Time to Revisit Your Constraints

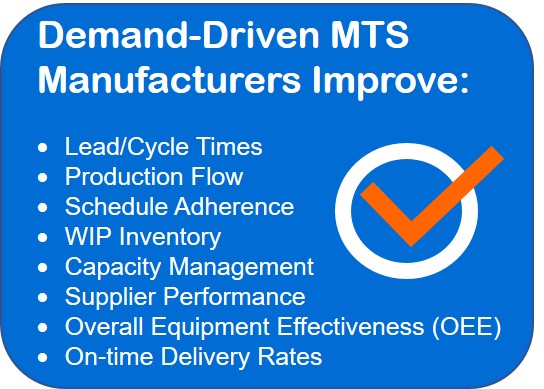

We talk a lot about constraints management in our work with customers who are implementing Demand-Driven Manufacturing (DDM) in their facilities. That’s because constraints management is fundamental for synchronizing the pace of production and keeping the demand (orders) flowing throughout the shop floor. But, our focus is naturally on physical constraints, e.g., that piece of equipment or workstation that is preventing you from delivering on time or offering