Production Planning and Scheduling

Data. People. Materials. Machines. Every resource key to your entire production process and extended supply chain manufacturing planning and scheduling processes to eliminate chaos and lower costs sounds great. But to do it, you need to be in control. In real-time. Minute-to-minute. Synchrono helps you take control in real time — minute to minute — to reduce delays, increase throughput, and deliver measurable ROI.

Demand-Driven Production Planning, Scheduling, and Execution Software

SyncManufacturing® software empowers demand-driven manufacturing by synchronizing and prioritizing the entire order-to-delivery cycle. This production planning and scheduling solution adapts to market changes instantly, keeping operations flowing, improving efficiency, and driving profitability. Learn more about demand-driven manufacturing.

- Create dynamic schedules

- Optimize shop floor workflow

- Maximize throughput

- Manage supply replenishment

- Drive on-time delivery

- Promote continuous improvement

Stay Ahead of Shifts in Demand

Adapt instantly to changes in demand—whether it’s a last-minute rush order, an order going on hold, or a sudden shift in priorities. Synchrono’s demand-driven manufacturing production planning and real-time scheduling software works in real time to automatically adjust production priorities across your operation.

No manual functions. No frantic emails or phone calls. Just a seamless, synchronized response that keeps production flowing and deadlines on track.

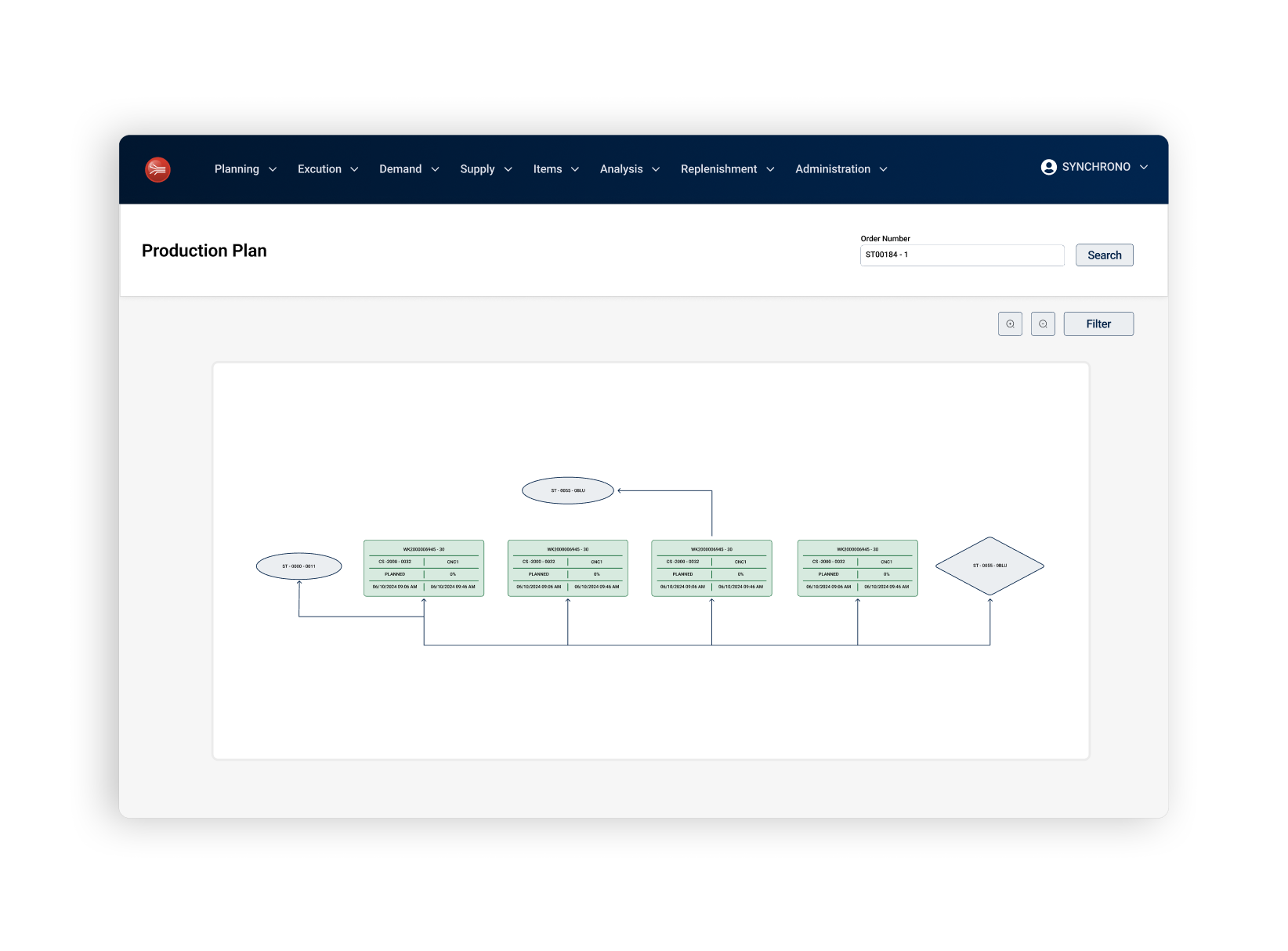

Gain End-to-End Operational Visibility

Eliminate scheduling chaos with SyncManufacturing®. It calculates materials, production availability, and constraints automatically, ensuring a smooth, efficient production process. Our exclusive CONLOAD™ technology aligns work release to the shop floor with actual constraints, clearing congestion and driving flow. Real-time manufacturing visualization connects everyone—production, supply chain, customer service, and sales—so decisions can be made faster and with confidence.

Manage and Reduce Variability in Production

Variability is inevitable—but how you manage it determines success. SyncManufacturing® software provides actionable insights to prevent disruptions, cut overtime, and reduce late orders. When priorities shift, the system automatically re-prioritizes and synchronizes every operation and material in real time—without any manual intervention.

Discover how understanding the difference between a bottleneck and a constraint in manufacturing can help you target variability at its root and keep production flowing smoothly.

Simplify Scheduling and Execution Across Teams

Break down silos and eliminate guesswork for sales, customer service, engineering, and purchasing. SyncManufacturing® software bases material release schedules on actual production and performance—not projections.

Seamless ERP software integration connects your planning, scheduling, and execution data across systems, ensuring every department works from the same real-time information. This reduces errors, improves responsiveness, and keeps your entire operation aligned with demand.

This alignment ensures execution runs smoothly across departments, improving responsiveness and customer satisfaction.

Continuously Improve Through Real-Time Insights

Turn data into actions that improve on-time delivery. SyncManufacturing® offers manufacturing analytics through powerful reporting tools and lean manufacturing tools to track, predict, and optimize operations. Easy-to-use drag-and-drop features simplify ischeduling changes, while web-based access means fast ROI and simple integration.

See how finite capacity planning can transform your scheduling process and deliver measurable results.

Synchronize and Prioritize Your Entire Supply Chain

Join manufacturers who’ve cut lead times by over 70% using Synchrono’s demand-driven production planning and scheduling solutions.