What is Demand-Driven Manufacturing?

Demand-Driven Manufacturing is a method of manufacturing where production is based on actual customer orders (demand) rather than a forecast. Gartner estimates that 90% of manufacturers who are not demand-driven, want to be. This is likely due to the many benefits Demand-Driven Manufacturing offers, including greater customer satisfaction.

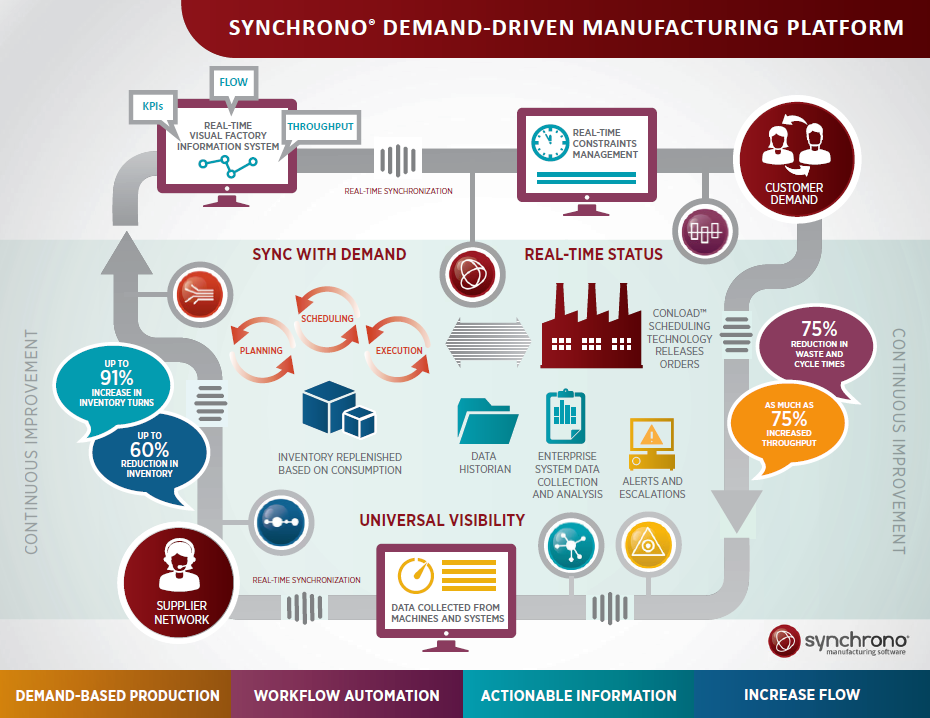

Synchrono® defines Demand-Driven Manufacturing as a method that incorporates the best of Lean Manufacturing, Theory of Constraints (TOC) and Six Sigma principles. It describes production that is based on actual customer demand with an aim to synchronize everything (people, method, materials, machines, and information) in order to drive flow. This process is accelerated by technology that automates, digitizes data and connects every function within the demand-driven organization and to every layer of the supply chain. The key components are synchronization and flow.

Demand-Driven Manufacturing enables a synchronized, closed loop between customer orders, production scheduling, and manufacturing execution – all while synchronizing the flow of materials and resources across the supply chain. The key components are synchronization and flow.

Demand-Driven Manufacturing enables a synchronized, closed loop between customer orders, production scheduling, and manufacturing execution – all while synchronizing the flow of materials and resources across the supply chain. The key components are synchronization and flow.

Demand-Driven Manufacturing is associated with “Response Planning” or “Pull” manufacturing and supply chain methods. The two main continuous improvement approaches that advocate the Demand/Pull method are Lean Manufacturing and Constraints Management.

Lean Manufacturing, Constraints Management and Lean Six Sigma believe that managing variability is of vital importance to any continuous improvement effort. You will see elements of these methodologies throughout Synchrono® systems and the Synchrono® Demand-Driven Manufacturing Platform.

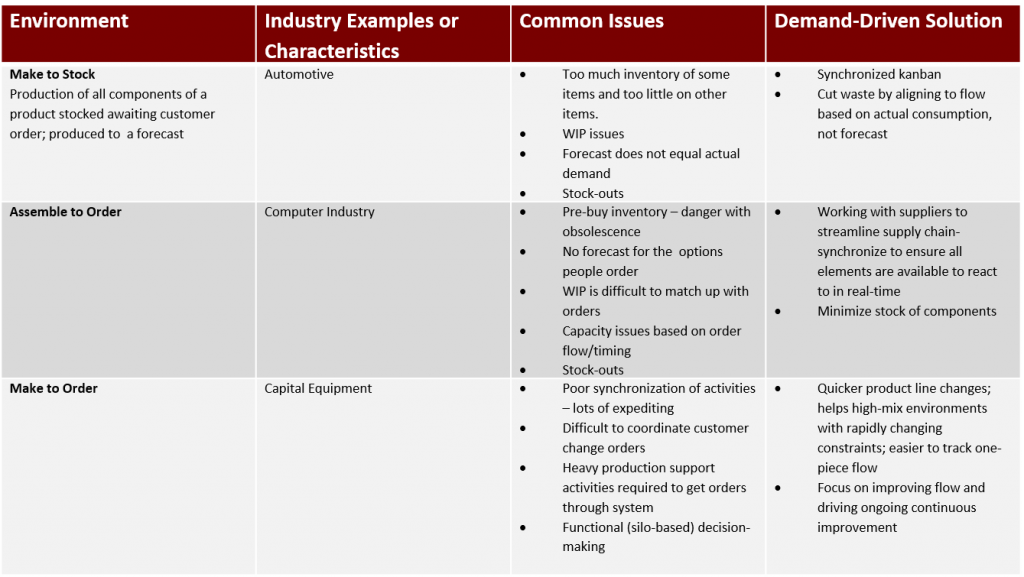

Environments for Demand-Driven Manufacturing

Demand-driven principles can be used in nearly every manufacturing environment because the focus is on flow through the factory. In make-to-stock (MTS) environments, a Demand-Driven Manufacturing platform can drive immediate improvements by right-sizing inventory, increasing flow and throughput, and replenishing resources using a kanban system. These improvements can be extended across the entire supply chain. In a make-to-order (MTO), engineer-to-order (ETO), and configure-to-order (CTO) environments, a demand-driven manufacturing planning, scheduling and execution approach delivers increased flow, throughput, on-time delivery and clarity throughout the manufacturing process and the extended supply chain.

In any environment, a Demand-Driven system will synchronize process, people, machine, materials, method and information. During execution, work released to the shop floor is in full alignment with the capacity of the constraint, minimizing work-in-process (WIP) and driving flow. Order statuses (and any associated disruptions) are visible throughout the enterprise – to the production team, supply chain management, customer service, sales and leadership. Everyone is working from the same factual, real-time information.

A sample of common challenges and demand-driven solutions for different manufacturing environments.

Constraints Management

Because Demand-Driven Manufacturing environments are more agile and adaptive, they are in a better position to manage and leverage constraints in the system. For example, in some environments, a particular machine or work cell may be a constraint. Demand-Driven Manufacturers know how many units the constraint can handle at a time, and will release work into the system accordingly. Doing so keeps flow at its peak throughout the production process, eliminating bottlenecks, aging WIP and inventory. Check out our paper, Eliminate Production Bottlenecks; Manage Manufacturing Constraints for more information on strategies to address these inhibitors to production flow.

Synchrono® developed CONLOAD™, a patented method for gating work into the system based on the capacity of constraints. CONLOAD™ is a component of SyncManufacturing® software for demand-driven manufacturing planning, scheduling and execution. If you would like to see how CONLOAD™ works, this video provides a good overview: CONLOAD™ Scheduling Methodology Video

To further examine how manufacturing planning, scheduling and execution works in a demand-driven environment, read the Synchrono® white paper, The Next Generation of Planning and Scheduling Solutions. There are also several case studies available that illustrate how Demand-Driven Manufacturing systems work in various environments.

Demand-Driven Business Value

Evidence from existing Demand-Driven Manufacturing environments supports the evolution to this method. Some of the results that synchronized, technology enabled, Demand-Driven Manufacturers have experienced include:

- Lower operating expenses – many Demand-Driven Manufacturers gain greater visibility, allowing them to curtail waste, lower WIP and align around flow—creating more business value in the form of profitability and reduced expenses

- Greater inventory control – customer orders mandate inventory consumption—advanced demand-driven software systems spark only what is needed to meet demand

- Workforce and processes aligned around flow – when manufacturing planning, scheduling and execution are synchronized with demand, everyone is aligned to address constraints, enhance flow and increase capacity

- Increased throughput – based on better control of flow, visibility and constraints management, more throughput is generated, which is directly tied to profitability

- Customer orders drive actions – everything is triggered by customer orders, so consumption becomes more effective

- Metrics work because they use real-time intelligence – signals from every step in the process are integrated by connected systems, providing solid direction for continuous improvement initiatives and metrics that reflect a “single version of the truth”

- Effective use of resources creates more profitable growth opportunities – eliminate waste and free up capacity to grow product lines or expand into new markets without added overhead

- Marketplace/competitive advantage – customers get what they want when they want it and you become the preferred vendor

Demand-Driven Manufacturers also experience savings in the form of cost-avoidance. Investing in technology can often avoid costs associated with business growth, such as adding headcount; physical space for additional product offerings or expanded volume; and the costs associated with manual processes and expediting. Consider the money that you don’t have to spend when making a business case for synchronized production systems.

Learn more about how Demand-Driven Manufacturing drives business value by reviewing the white paper, Why Become More Demand-Driven? Responding to Customer Needs.

The Industrial Internet of Things

Demand-Driven Manufacturing and the Industrial Internet of Things (IIoT) go hand in hand. For manufacturers, the IIoT is the ability to collect, analyze and share data about materials, machines and processes in the production environment, in real-time. The power of this level of information is unquestionable.

Research has shown that connected factories will use this new intelligence to become more demand driven, and thus increase their competitive advantage. They pull together machine-level, inventory management, supplier and customer data – and transform it into actionable information. This information provides a big-picture view that identifies disruptions in real-time, coordinates a fast and effective response, and logs the cause and impact to direct continuous improvement efforts.

More information about the connection between Demand-Driven Manufacturing and the Industrial Internet of Things is in the white paper, How Technology Will Connect Your Enterprise and Create the Demand-Driven Factory of the Future – Today and in the industry brief, The Industrial Internet of Things.

Demand-Driven KPIs

The Key Performance Indicators (KPIs) monitored in a Demand-Driven Manufacturing environment track the demand signal through the entire organization. The results measured are those related to flow, velocity, throughput, and other measures of movement throughout the supply chain. These KPIs are often used to guide the organization to areas of focus for continuous improvement. Finally, the true key performance indicator for Demand-Driven Manufacturers is on-time delivery.

Flow-Based Metrics

The demand-driven factory performs to flow-based metrics that are (ideally) visible to everyone on a shared technology platform in a connected enterprise. Production leaders predict and plan using three primary demand-driven metrics from Dr. Eliyahu Goldratt’s book, The Goal:

- Throughput – throughput is calculated as the selling price of the product minus totally variable costs per unit.

- Investment (inventory) – All the money currently tied up in the system, which the company intends to sell.

- Operating expense – All the money the organization spends in turning Investment into Throughput.

High-performing delivery KPIs and metrics – coupled with customer satisfaction – open up additional business opportunities based on expanded capacity and enhanced resource utilization. To examine the KPIs met (and dramatic results realized) using Demand-Driven Manufacturing systems, see Synchrono® case studies.

Why Become Demand-Driven?

Demand-driven factories can deliver on-time orders more reliably and gain capacity to grow and meet future customer needs. As information is gathered by Demand-Driven Manufacturing software systems and placed in front of the people who need to act—they become more empowered and informed to improve the way things are done. The intelligent environment gives employees clarity about what is the number one thing they could be doing right now to improve overall company performance and the information to determine how to approach it. By shortening reaction time to disruptions and bottlenecks, and by focusing on the true driver of sustained growth—improved flow – they can exceed customer expectations. World-class effectiveness in the service of the customer order (and becoming more productive when looking for ways to meet customer needs in advance by continuously improving) is how manufacturers unleash growth in a synchronized, demand-driven environment.

In using demand-driven principles and synchronized systems, manufacturers have learned to reach new levels of communication, growth and customer responsiveness. Every forward-thinking manufacturing environment is somewhere on the path toward becoming more synchronized and demand-driven. Where are you?

For additional information on various aspects of Demand-Driven Manufacturing, visit the blog, Demand-DrivenMatters.com.