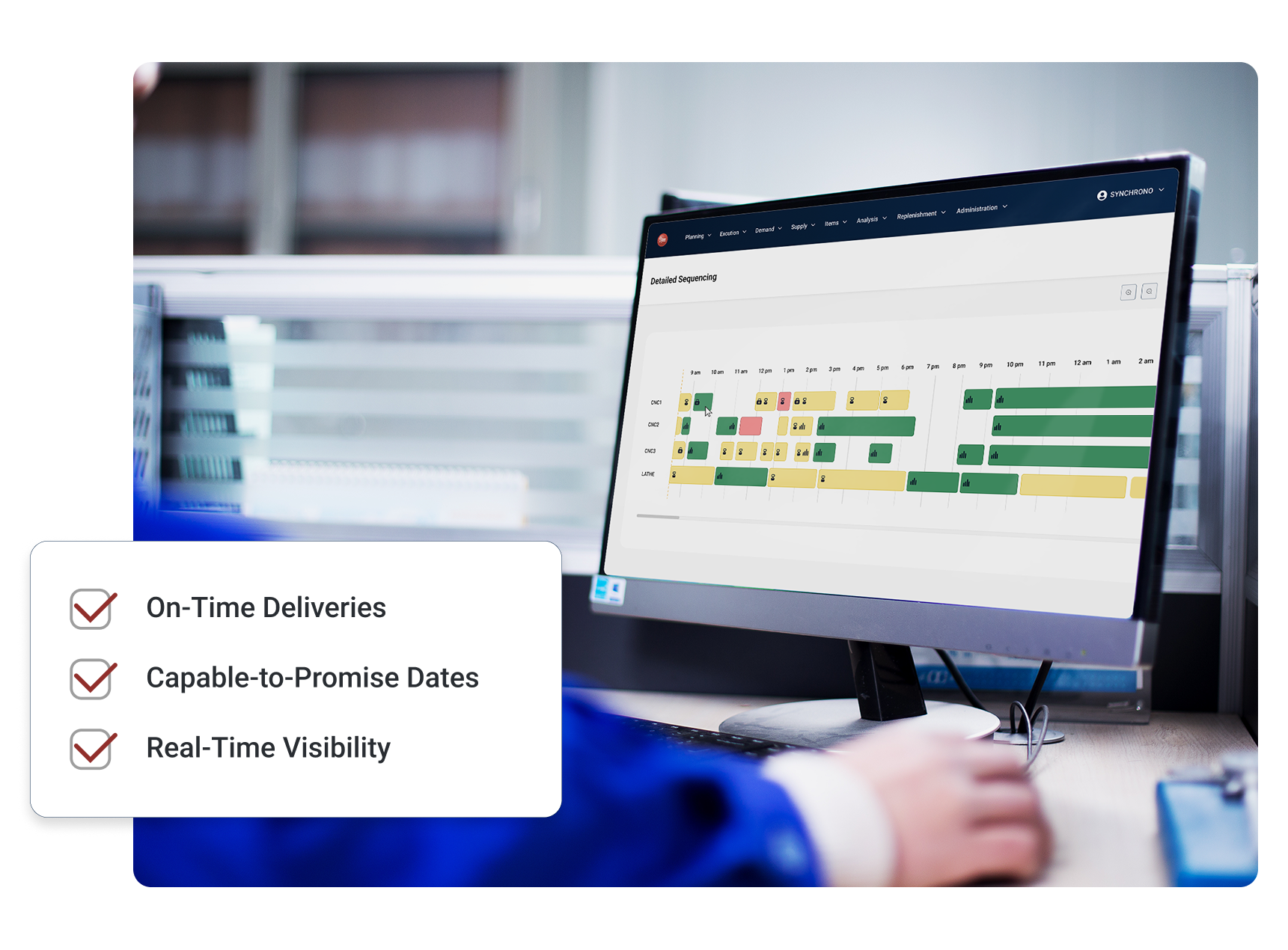

Advanced Planning and Scheduling Software

SyncManufacturing® is advanced planning and scheduling software powered by demand-driven, constraint-based algorithms. It synchronizes and prioritizes the entire order-to-delivery process in real-time, helping manufacturers meet on-time deliveries, reduce lead times, and increase throughput.

Transform Schedule Builders into Schedule Analyzers

Equip planners and schedulers with software designed to prioritize what truly matters at the right time. SyncManufacturing handles the heavy lifting, providing your team with a smarter and more efficient way to work.

Stop Rebuilding Schedules

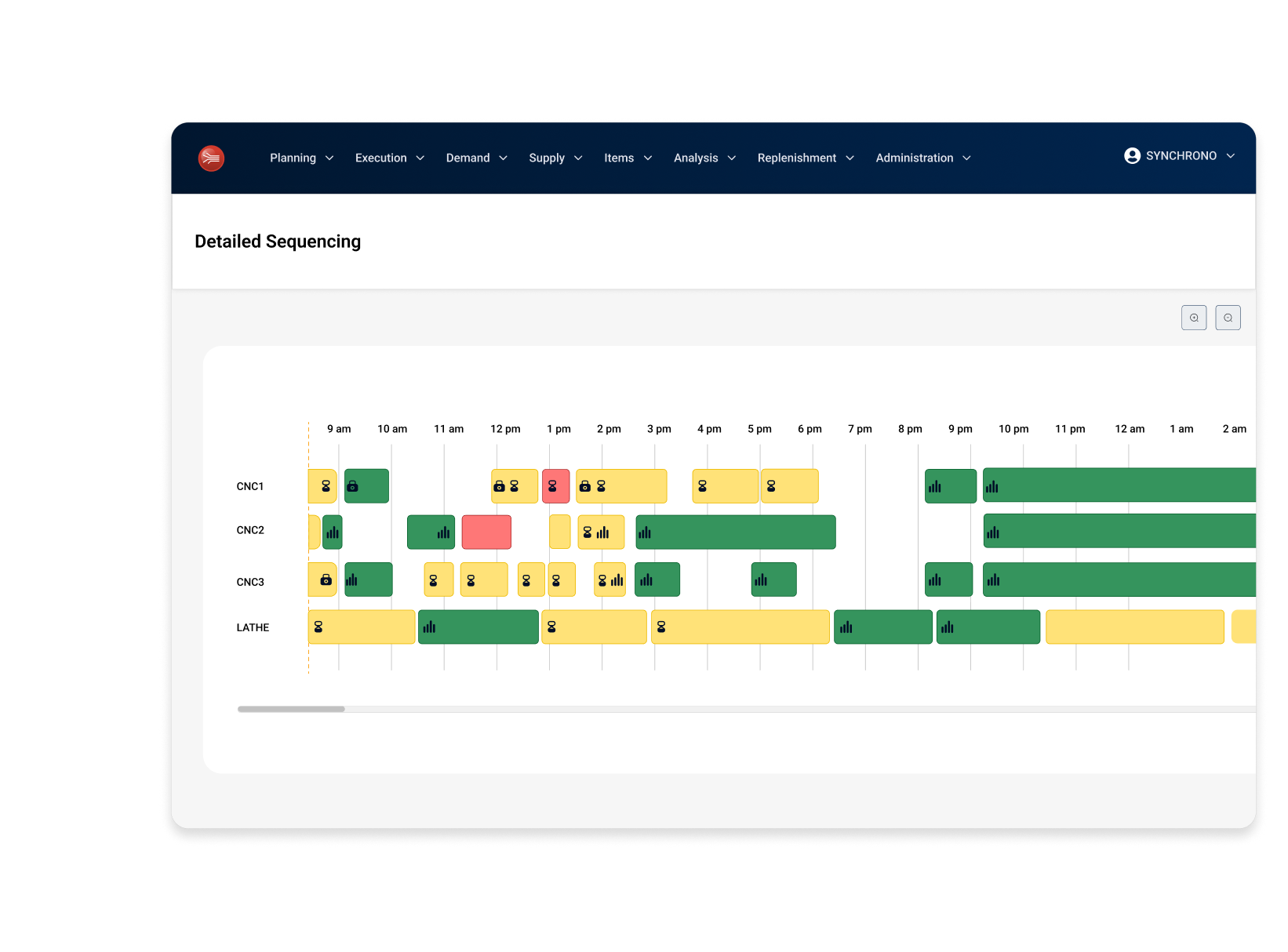

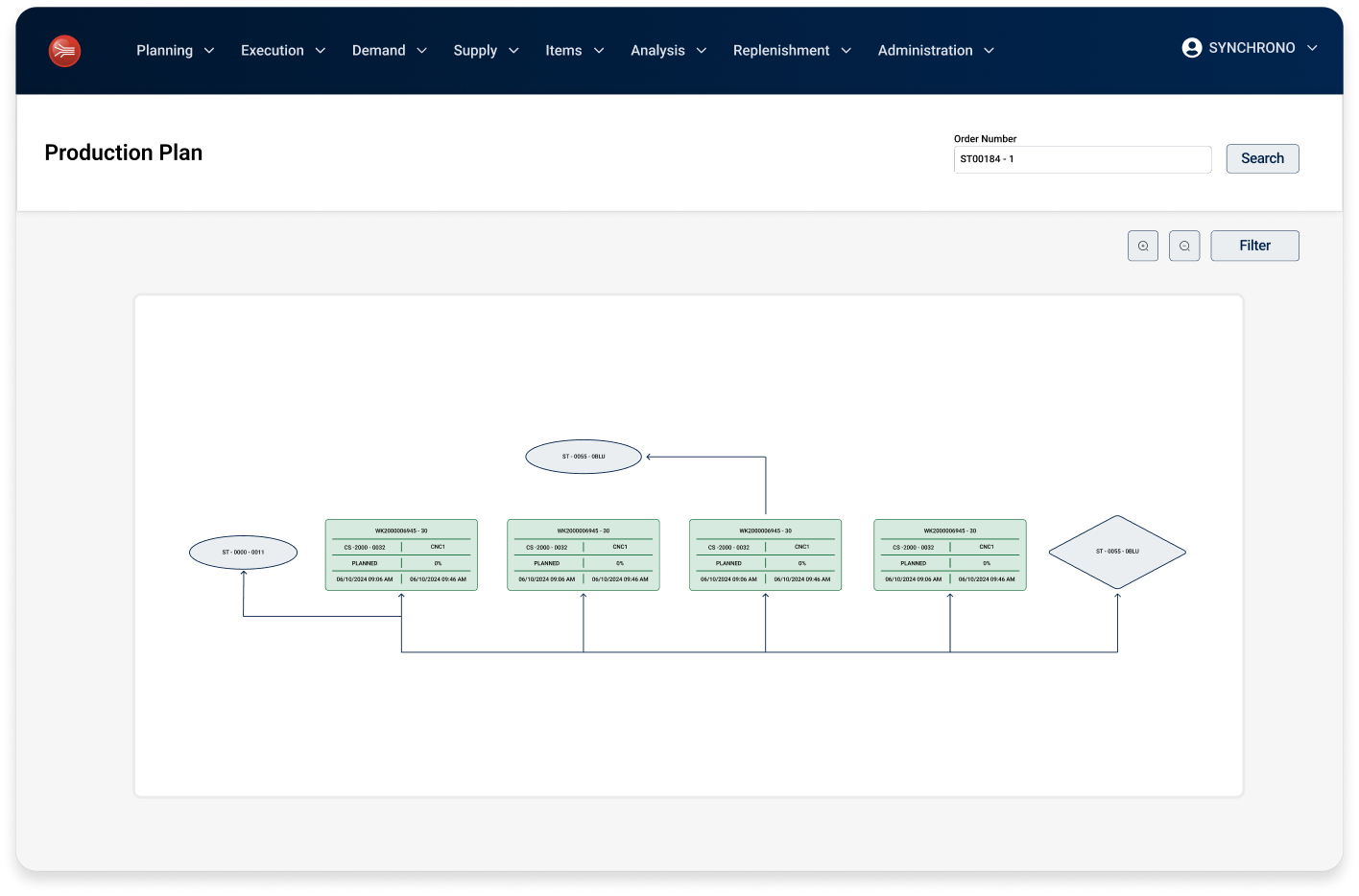

Instead of manually rebuilding schedules, spend time analyzing and optimizing them. SyncManufacturing eliminates repetitive tasks, freeing up valuable hours.

Leverage Advanced Algorithms

Powerful algorithms automatically optimize workflows, ensuring your operations run smoothly and efficiently, even in unexpected changes.

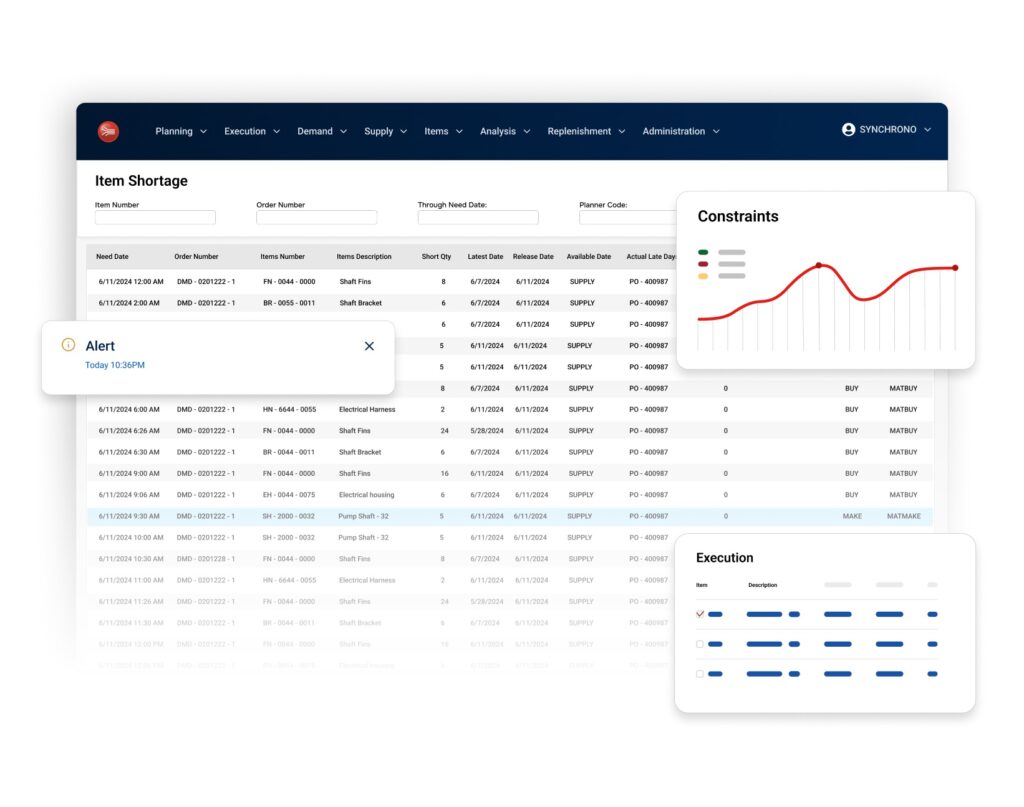

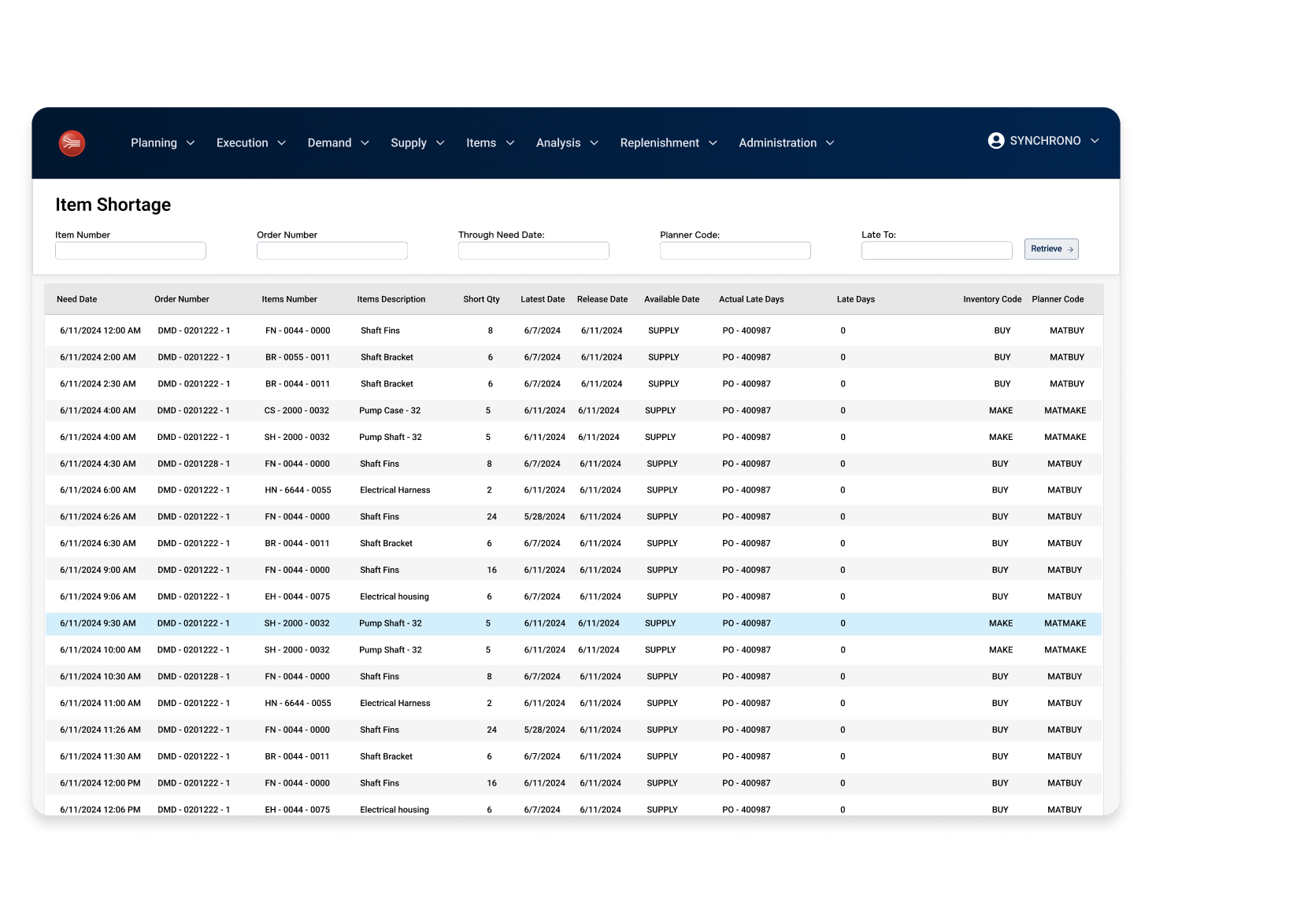

Data-Driven Decision-Making

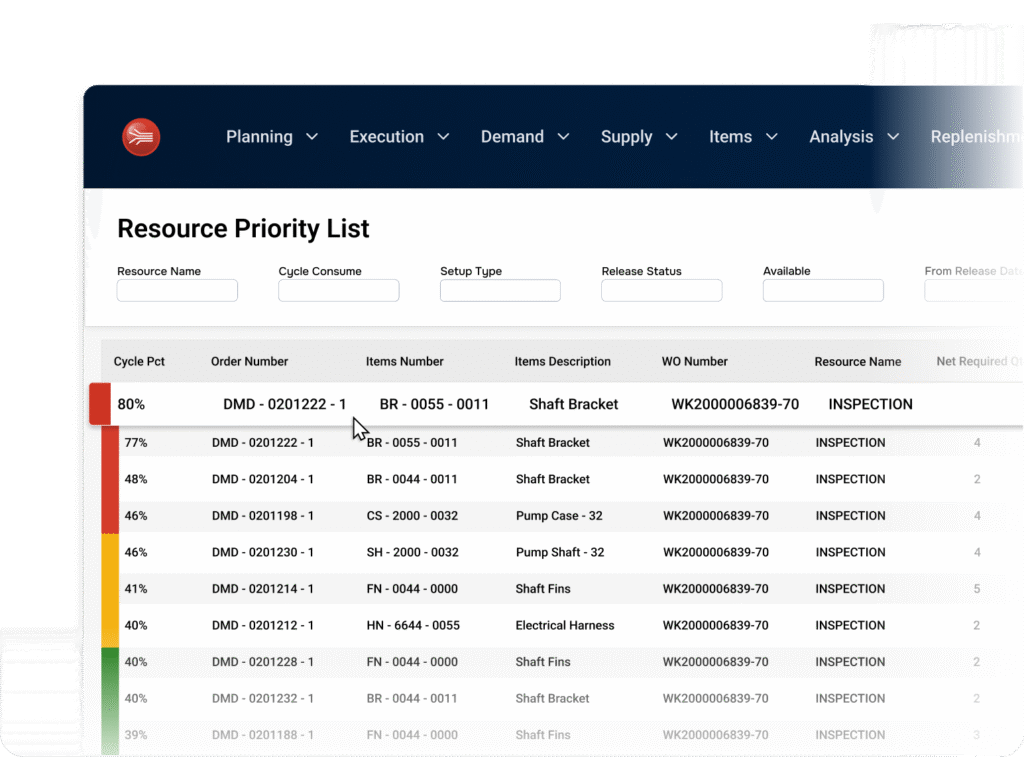

Access comprehensive, real-time data, allowing smarter, faster decisions. Visualize bottlenecks and constraints and plan ahead with confidence.

Stay Ahead and Stay Aligned

Enable real-time, mission-critical information at the fingertips of everyone in the organization. Your team can make faster, more accurate decisions for proactive problem-solving and continuous improvement.

Complete Operational Visibility and Response

Never lose sight of your priorities and actions. Achieve fully synchronized operations where every role and relationship is known, creating end-to-end visibility and management.

Best-In-Class for 25 Years

SyncManufacturing has remained unrivaled in its class. It’s innovative production planning and scheduling software handles complex and diverse environments by combining constraint management, lean manufacturing, smart factory, and IoT.

From 3-4 Weeks to Under 5 Days

Reduced Lead Times

Doubled Revenue

In 2.5 Years

From 50% to 98%

Improved On-Time Shipments

Manufacturing Environments SyncManufacturing Supports

Automate Production Planning and Scheduling

SyncManufacturing is a scalable system that gives you the competitive edge you need in today’s dynamic manufacturing landscape. Request a demo of SyncManufacturing to learn more.