Advanced Planning and Scheduling for Medical Device Manufacturing

SyncManufacturing® Advanced Planning and Scheduling (APS) software plays a critical role in helping medical device manufacturers meet their objectives by synchronizing production processes and optimizing resource utilization. This sophisticated system allows manufacturers to adapt to the complex and highly regulated environment of medical device production, where precision, quality, and adherence to strict standards are paramount.

What is Advanced Planning and Scheduling Software

APS software helps production planners and schedulers optimize production to meet demand and improve manufacturing efficiency by aligning workflow to actual demand and resource availability. Unlike traditional Material Requirements Planning (MRP) solutions, APS considers capacity constraints (finite capacity planning), inventory availability, and lead times to create schedules that optimize production performance. By synchronizing materials, capacity, and labor with demand, APS can improve resource utilization and ensure equipment and people are effectively deployed to meet delivery commitments while minimizing waste and costs.

Improve Customer Service

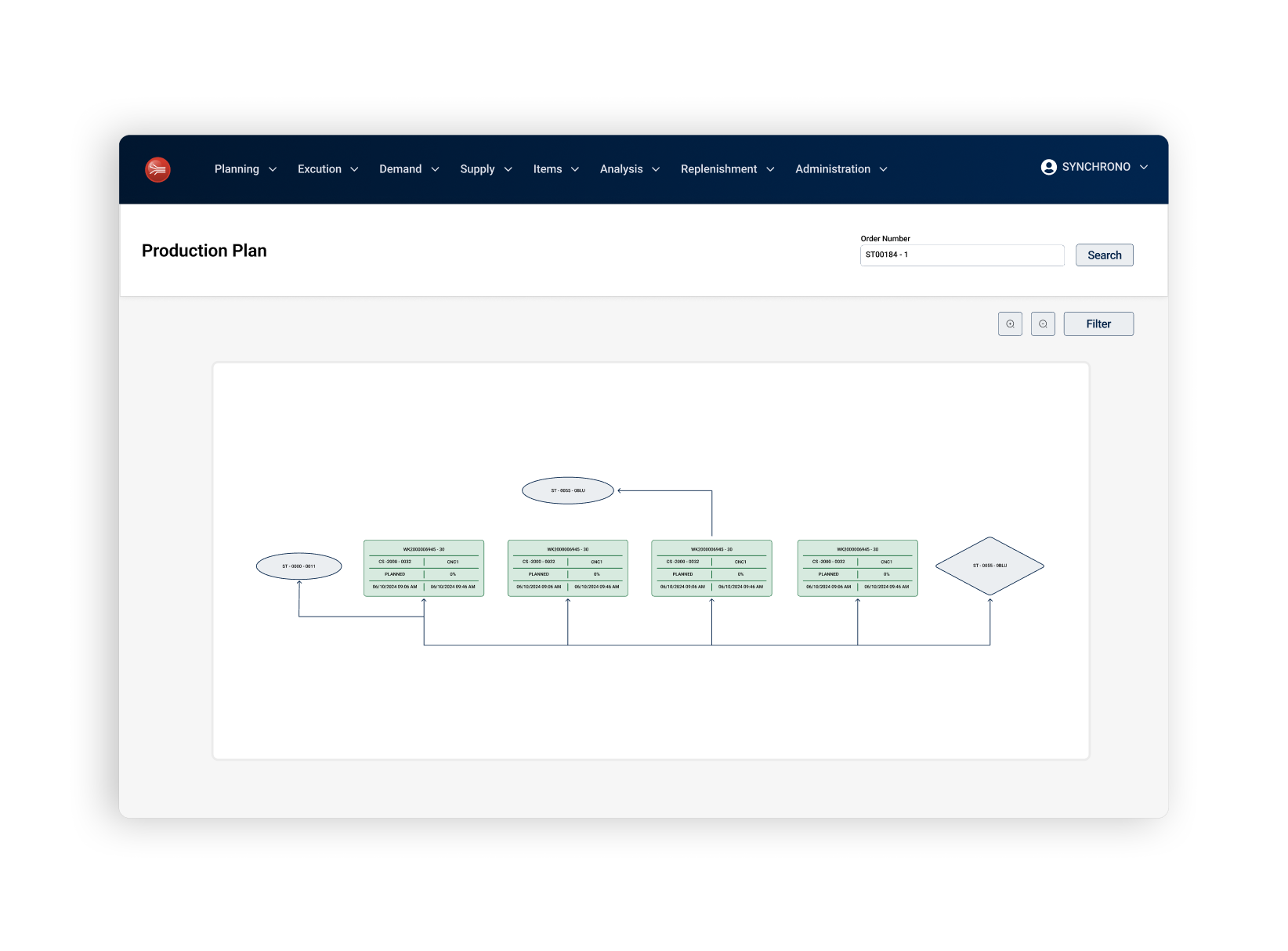

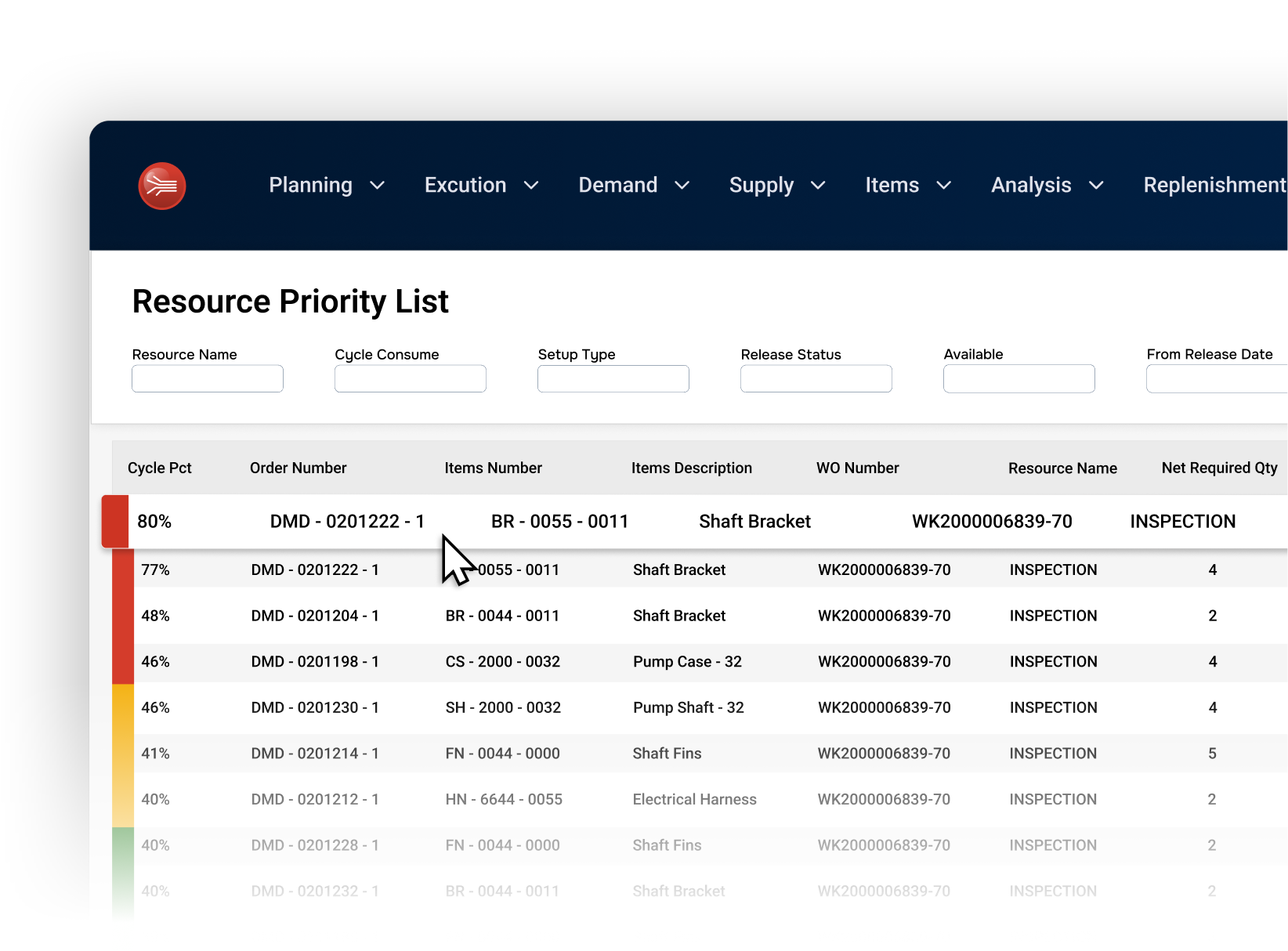

In a highly competitive market, customers want to work with medical equipment suppliers who can meet their commitments and have their products available when and where they need them. SyncManufacturing finite capacity scheduling algorithms consider material availability as well as equipment and workforce constraints, allowing customer-facing employees to provide realistic capable to promise dates that build customer trust. Unlike many other production scheduling tools, SyncManufacturing even allows you to build QC processes into production workflows.

Shorten Cycle Times

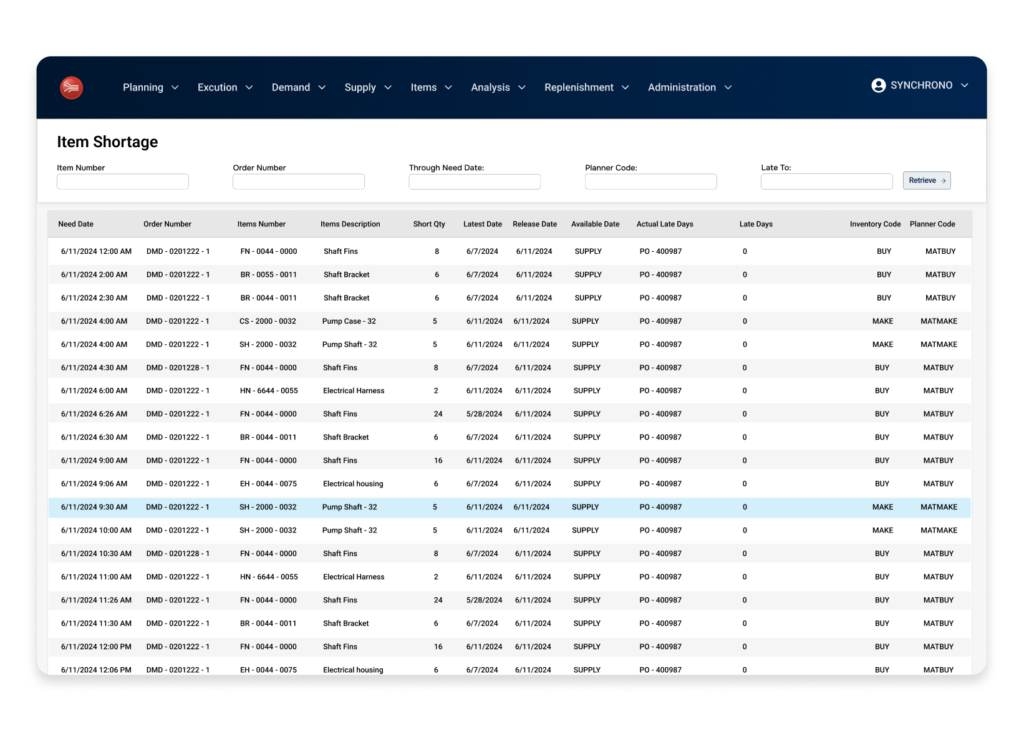

The SyncManufacturing dashboards highlight areas that may require intervention so planners and schedulers can address issues before they create delivery schedule delays. SyncManufacturing can also help identify the real bottlenecks in your production workflow, giving you the insights you need to identify areas for continuous improvement and accelerated throughput.

Adjust Production Planning in Real-Time

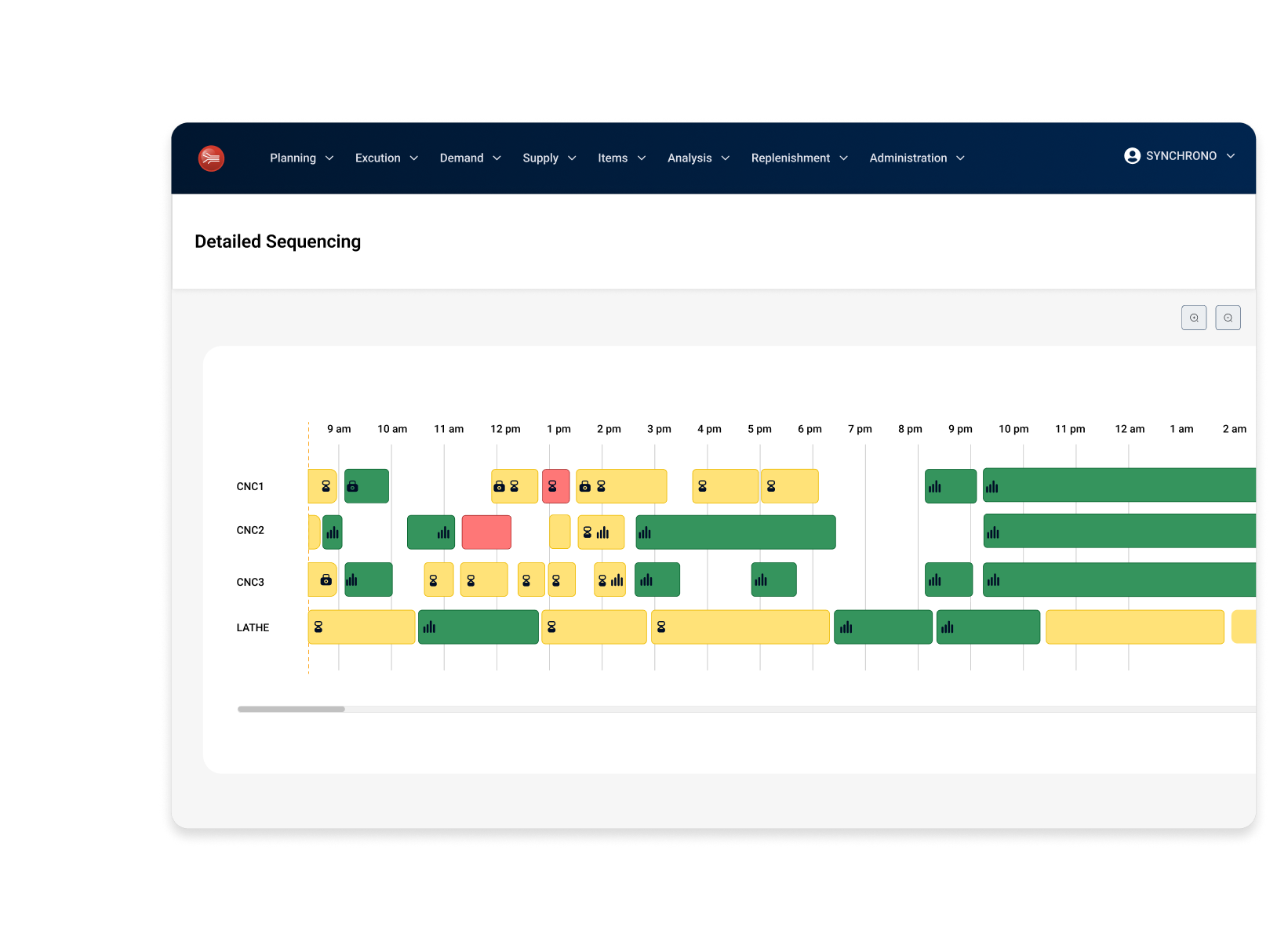

If building your medical devices requires special equipment or workers with unique skills, sudden changes to resource availability can have a ripple effect throughout the factory. Rush orders, material shortages and supply chain delays can be just as disruptive. SyncManufacturing dynamically adjusts production schedules, including dependencies, to resource capacity and availability.

Reduce WIP

By aligning production schedules to production constraints and resource capacity, SyncManufacturing can help manufacturers reduce their WIP inventory levels. Lower levels of WIP can also help medical device manufacturers lower defect rates and raise yield rates as lower WIP reduces the time between manufacture and inspection, ensuring that issues are found before the entire lot is built.

Increase Resource Utilization

Manufacturing equipment is a key expense, and the right manufacturing talent can be hard to find, so maximizing resource utilization is critical. SynchManufacturing’s finite capacity scheduling algorithms allocate production across available resources (materials, equipment, and people) within their limitations. In addition to maximizing resource utilization, finite capacity scheduling improves production throughput by minimizing idle time.

Power Up Your Performance

Give your continuous improvement initiatives the boost they need with these SyncManufacturing add-ons.

SyncAlert®

Monitor and manage production performance from your mobile device. Receive alerts when issues need to be addressed and assign action items to the appropriate personnel.

SyncKanban®

The ultimate in lean replenishment techniques, our eKanban application aligns replenishment signals to actual demand. SyncKanban® can even dramatically resize your Kanban loops.

SyncView®

Have targeted KPIs? SyncView® provides a real-time, visual representation of factory performance. Dashboards can be defined by user type for targeted insights and improved focus.

Synchronize Your Operations with SyncManufacturing

Manufacturing optimization requires breaking down silos within the organization so that every department and every team can work together toward a common goal. SyncManufacturing from Synchrono gives your entire team the visibility they need for faster decision-making and alignment to the organization’s top priorities. When you’re ready to transform your organization into the highly calibrated, profit-producing engine it was meant to be, reach out to us or request a live demo.