Constraint-Based Scheduling for Discrete Manufacturing

Synchrono® delivers advanced manufacturing software solutions designed to help discrete manufacturers solve complex scheduling problems and achieve synchronized operations. At the heart of our approach is constraint-based scheduling, a methodology that prioritizes system capacity, customer demand, and flow to create realistic, executable production schedules. Unlike traditional planning tools, constraint-based methods focus on capacity of critical resources rather than assumptions. This ensures that your production schedule reflects actual conditions on the factory floor and leads to measurable improvements in efficiency and on-time delivery performance.

Why it matters:

- Finite capacity planning that respects real-world resource limits.

- Real-time production scheduling that dynamically adapts to changes.

- Integration with ERP and factory systems for enterprise-wide alignment.

The Problem with Traditional Scheduling

Legacy MRP systems and spreadsheets rely on forecast-driven, push-based logic. These methods create unrealistic plans, drive excess inventory, and lead to constant expediting. In many cases, they worsen scheduling problems by ignoring system constraints and causing misaligned priorities.

When teams rely on outdated tools, lead times often stretch unpredictably, production capacity is overcommitted, and customer commitments are missed. This approach not only undermines efficiency but also makes it impossible to compete in fast-moving markets.

How Constraint-Based Scheduling Works

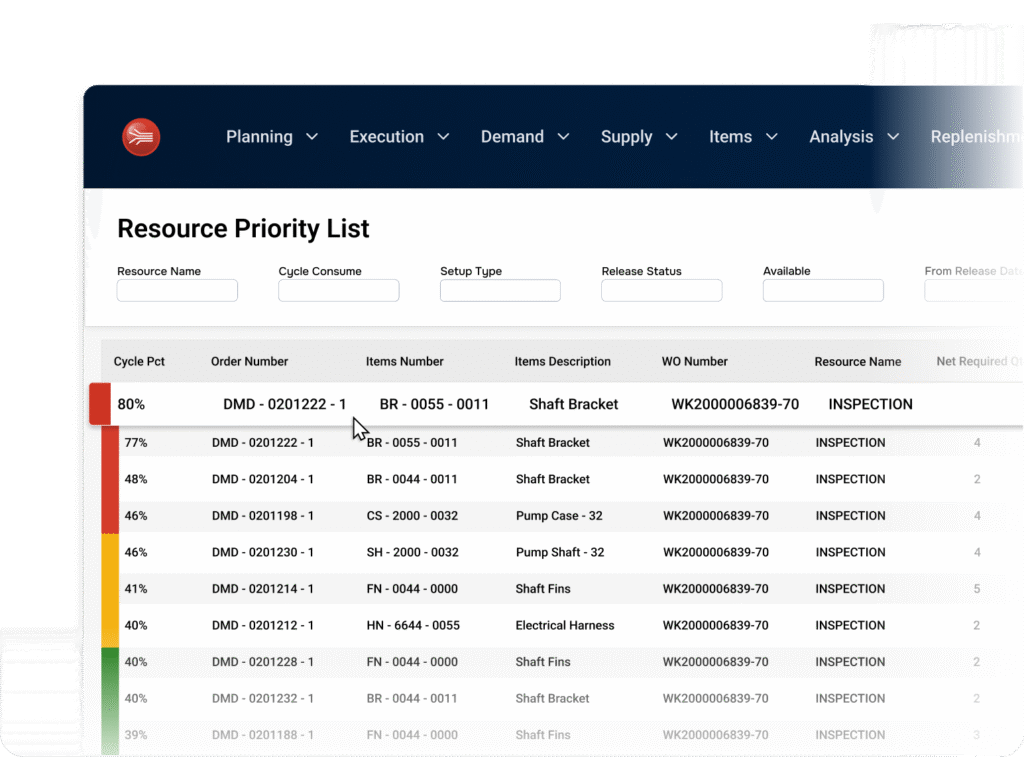

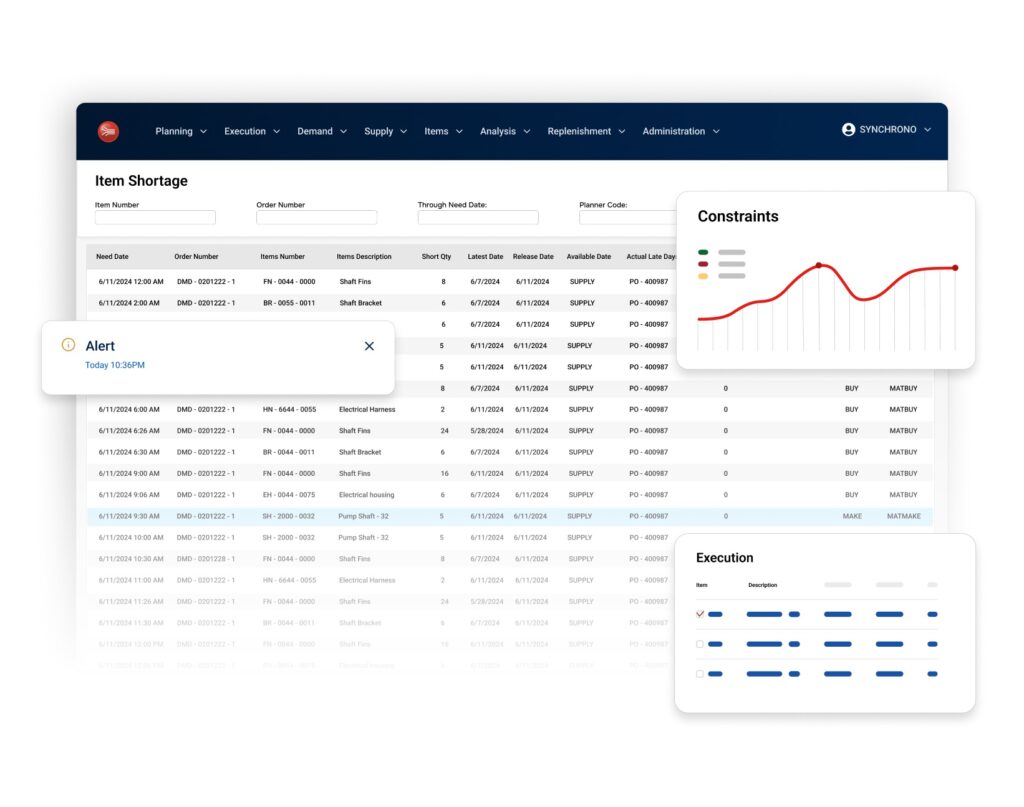

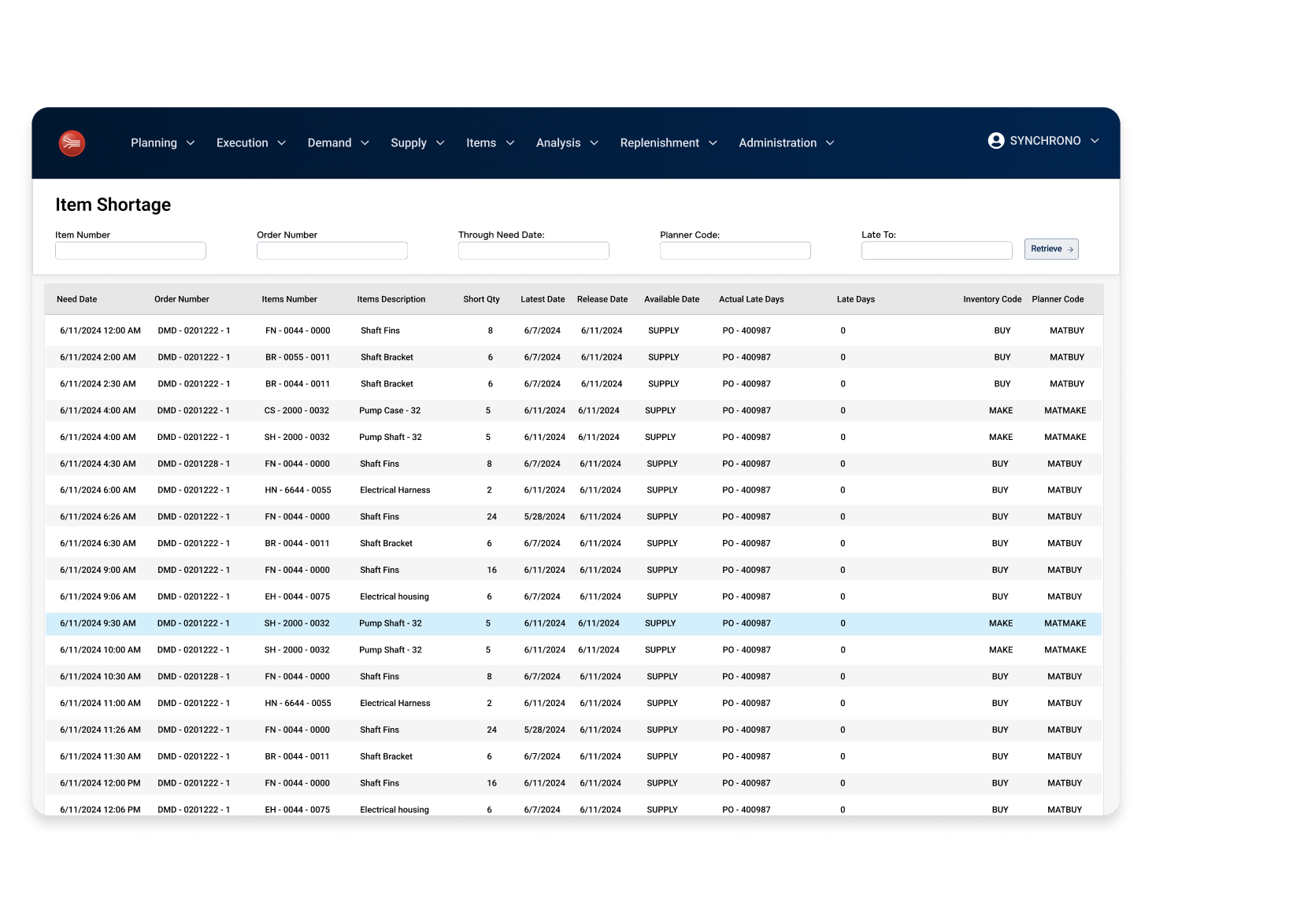

Constraint-based scheduling introduces a smarter way of working by synchronizing production to the actual capacity of your system. This is achieved by controlling work release, prioritizing key constraints, and balancing flow across machines, materials, and labor.

Drawing from Theory of Constraints scheduling, Lean principles, and demand-driven scheduling, this method focuses on flow and responsiveness. It replaces forecast-driven planning with demand signals, allowing manufacturers to reduce excess inventory, shorten lead times, and ensure continuous throughput.

For example, in industries with complex assemblies, scheduling constraint examples may include machine availability, setup times, labor shifts, or supplier lead times. By incorporating these variables, constraint-based schedules are practical, achievable, and designed to maximize efficiency.

Why Manufacturers Choose Synchrono®

For over two decades, Synchrono® has pioneered advanced scheduling and planning solutions for discrete manufacturers. The SyncManufacturing® APS platform integrates constraint-based methods with powerful analytics to deliver clarity, speed, and synchronization. Key reasons manufacturers partner with Synchrono® include:

- Deep expertise in finite capacity planning and resource alignment.

- Use of constraint programming techniques to model true system behavior

- Integration with Lean and Theory of Constraints scheduling frameworks

- Built-in support for understanding constraint differences to guide decision-making.

- Compatibility with pull-based manufacturing methods and demand-driven workflows

With Synchrono®, manufacturers gain more than software—they gain a partner committed to building resilient, synchronized operations that can thrive in today’s dynamic markets.