Advanced Planning and Scheduling for Wood Products Manufacturers

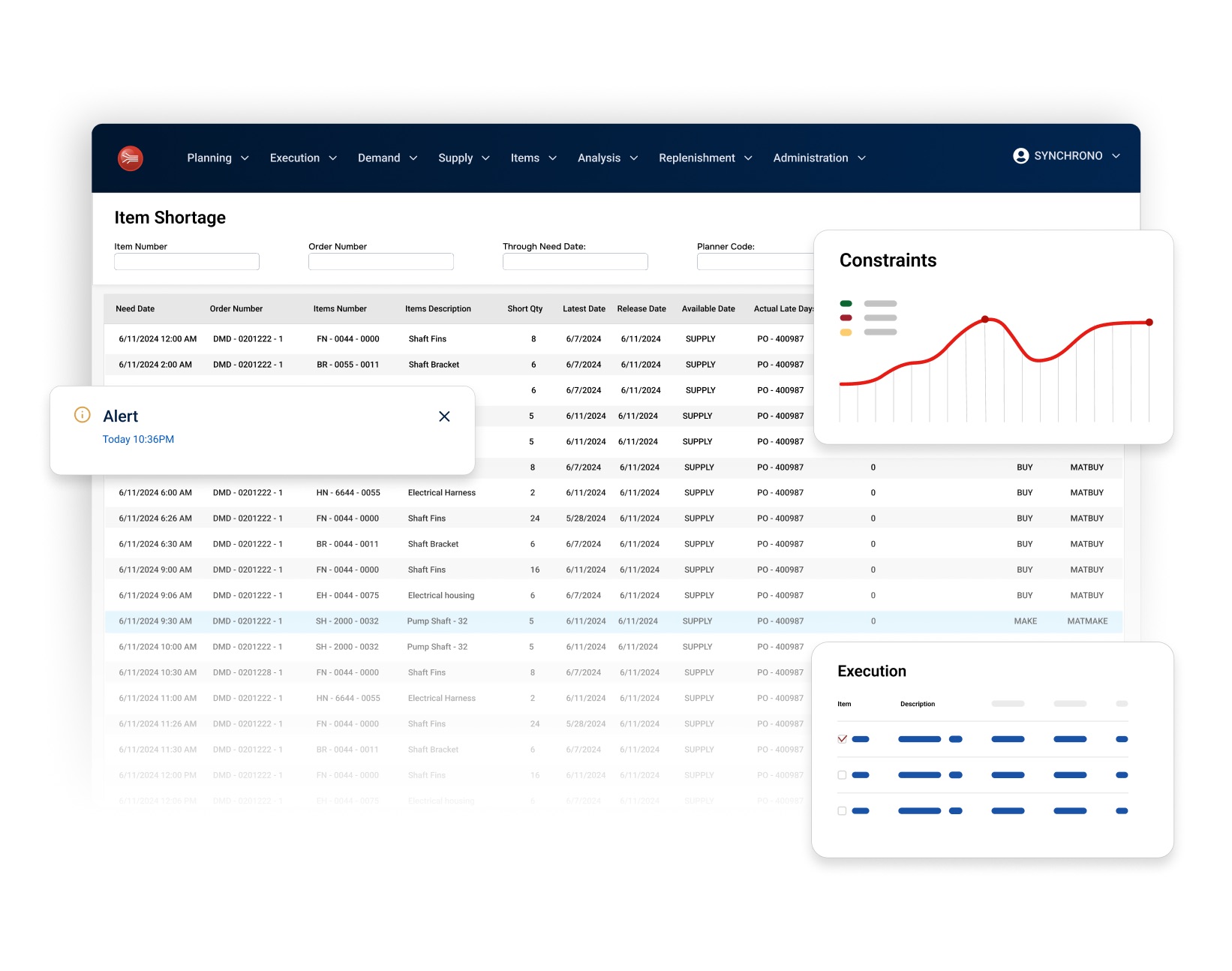

By aligning production to resource capacity, SyncManufacturing® Advanced Planning and Scheduling (APS) software plays a critical role in helping wood products manufacturers meet their objectives. This sophisticated system enables manufacturers to adapt to variability in raw materials and rapidly fluctuating demand patterns with highly detailed and realistic production schedules that account for resource availability, production constraints, and order deadlines.

What is Advanced Planning and Scheduling Software

APS software helps production planners and schedulers optimize production to meet demand and improve manufacturing efficiency by aligning workflow to actual demand and resource availability. Unlike traditional Material Requirements Planning (MRP) solutions, which focus on material availability alone, APS systems use finite capacity planning algorithms to align production schedules to real-time demand and factory capacity.

Improve On-Time Deliveries

Customers buy more from manufacturers they trust. Finite capacity scheduling algorithms consider equipment and workforce constraints as well as material availability, providing customer-facing employees with realistic capable to promise dates. Unlike many other production scheduling software applications, SyncManufacturing even allows you to build QC processes into production workflows.

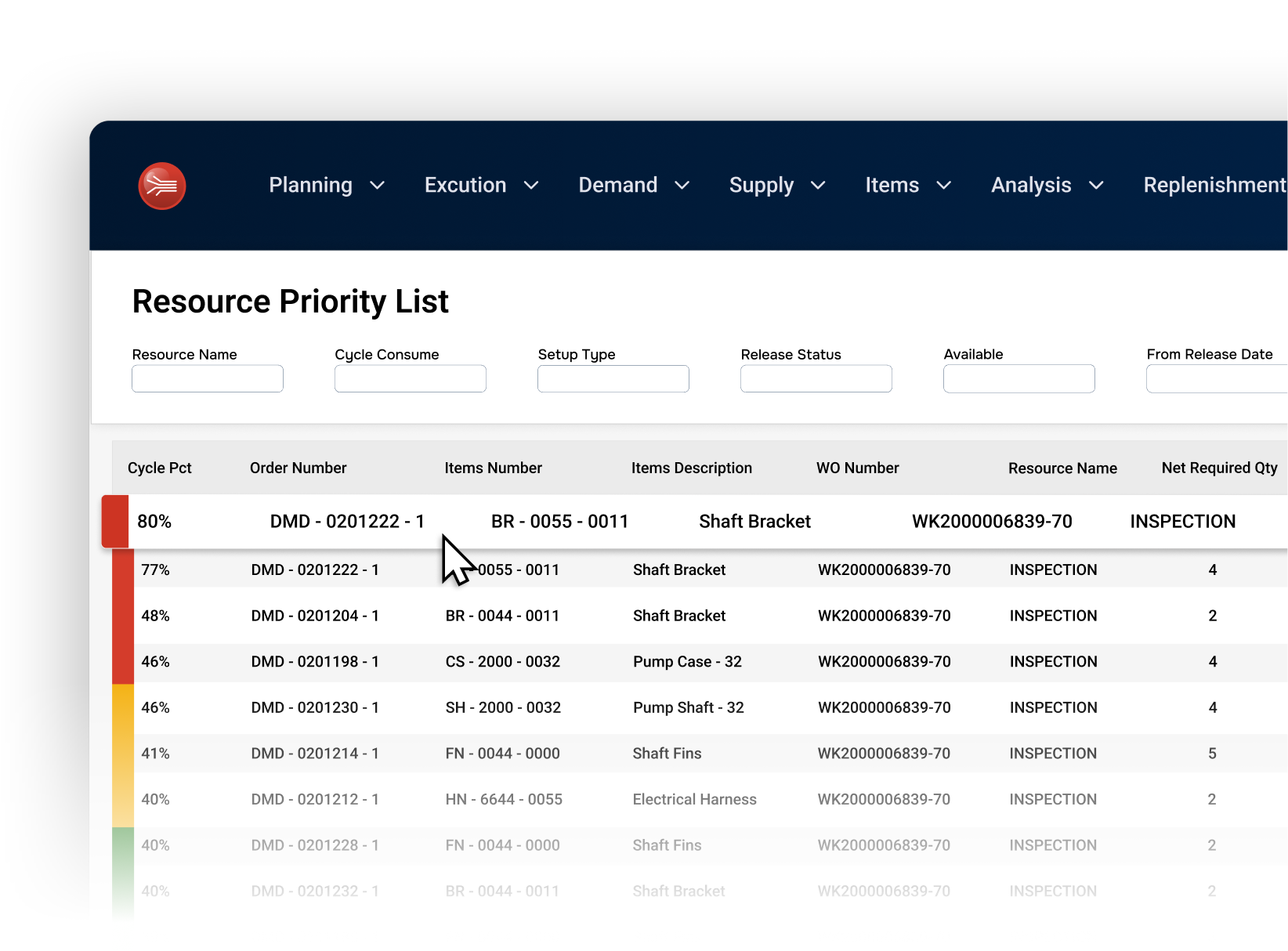

Optimize Resource Utilization

Crafting wood products often requires specialized talent and equipment. If you’ve invested in these areas, SyncManufacturing can help get the most from them. By aligning production to demand, our APS system helps wood products manufacturers minimize downtime, improve equipment utilization, and ensure employees are working on the right production orders at the right time.

Reduce WIP & Waste

By aligning production schedules to production constraints (bottlenecks) and resource capacity, SyncManufacturing can help wood products manufacturers reduce their WIP inventory levels. Lower levels of WIP often lead to lower defect rates and raise yield rates as WIP that spends less time queuing is less likely to be damaged.

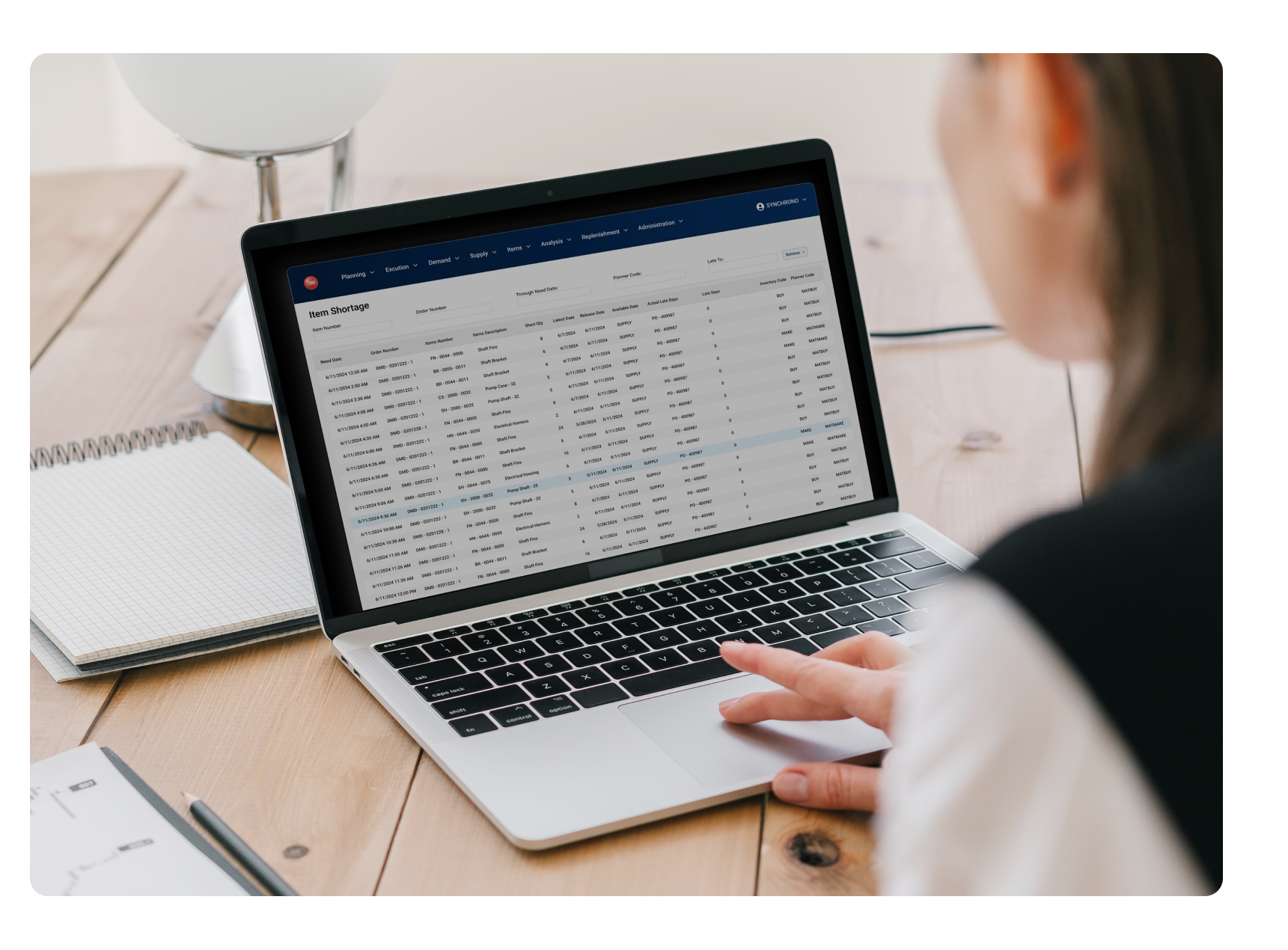

Increase Shop Floor Visibility

SyncManufacturing provides real-time insights into production processes, enabling data-driven decision-making and improved coordination across departments and multi-site operations. By increasing visibility into shop floor activities, SyncManufacturing allows for proactive responses to production demands and helps operations managers smooth production flow throughout the factory.

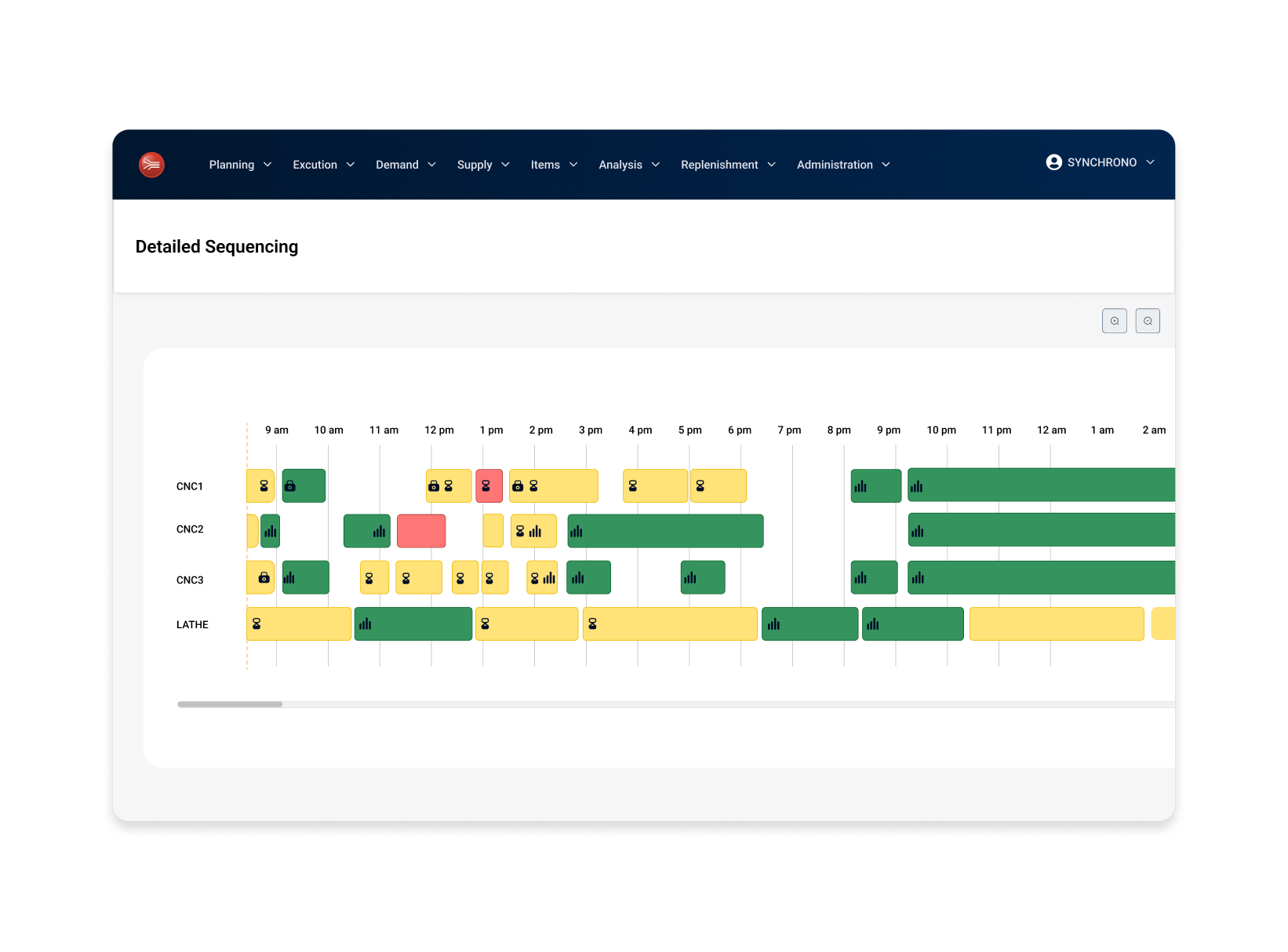

Adjust Production Schedules in Real-Time

Wood products manufacturers operate in a highly variable environment. Rush orders, material shortages/quality issues, supply chain delays, and more can require rapid adjustments to production schedules. SyncManufacturing dynamically adjusts production schedules, including dependencies, to current resource capacity, material availability, and operational priorities.

Power Up Your Performance

Give your continuous improvement initiatives the boost they need with these SyncManufacturing add-ons.

SyncAlert®

Monitor and manage production performance from your mobile device. Receive alerts when issues need to be addressed and assign action items to the appropriate personnel.

SyncKanban®

The ultimate in lean replenishment techniques, our eKanban application aligns replenishment signals to actual demand. SyncKanban® can even dramatically resize your Kanban loops.

SyncView®

Have targeted KPIs? SyncView® provides a real-time, visual representation of factory performance. Dashboards can be defined by user type for targeted insights and improved focus.

Synchronize Your Operations with SyncManufacturing

Manufacturing optimization requires breaking down silos within the organization so that every department and every team can work together toward a common goal. SyncManufacturing from Synchrono gives your entire team the visibility they need for faster decision-making and alignment to the organization’s top priorities. When you’re ready to transform your organization into the highly calibrated, profit-producing engine it was meant to be, reach out to us or request a live demo.