Advanced Planning and Scheduling Software for Discrete Manufacturers

Synchrono® helps manufacturers move beyond static tools with an APS solution that delivers real-time visibility, agility, and measurable performance gains.

Why APS Software Matters Now

For years, manufacturers relied on legacy planning tools like spreadsheets or traditional MRP systems. While these tools served their purpose in the relatively slow-moving and simplistic environments of the past, they are not built for today’s fast-paced, dynamic, and complex manufacturing operations and extended supply chains. Static, batch-driven scheduling cannot keep up with the pace of modern discrete operations.

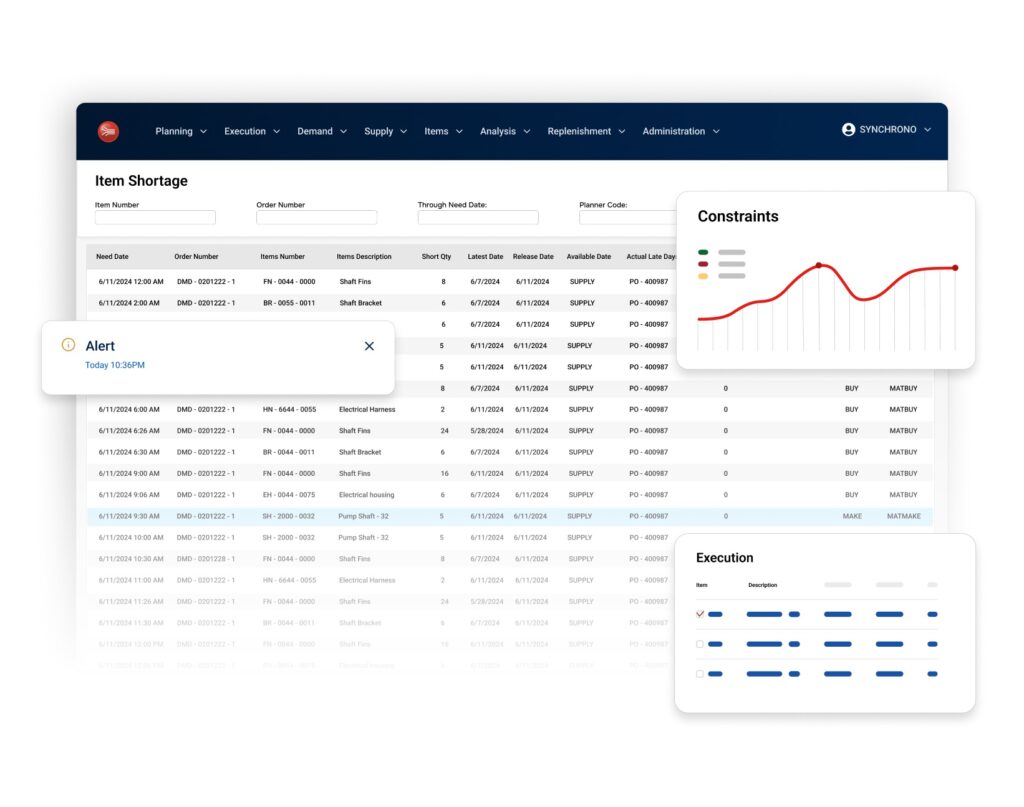

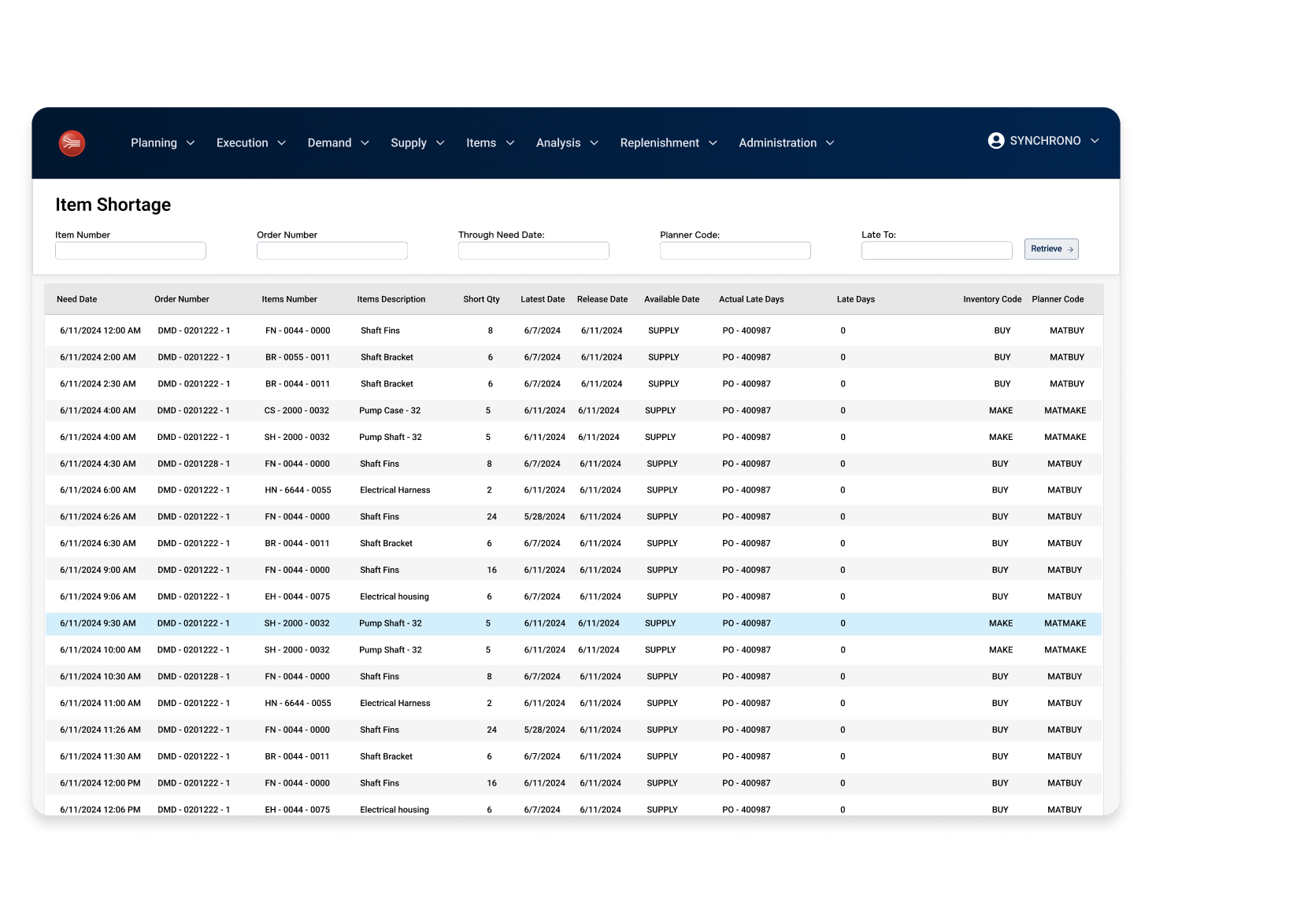

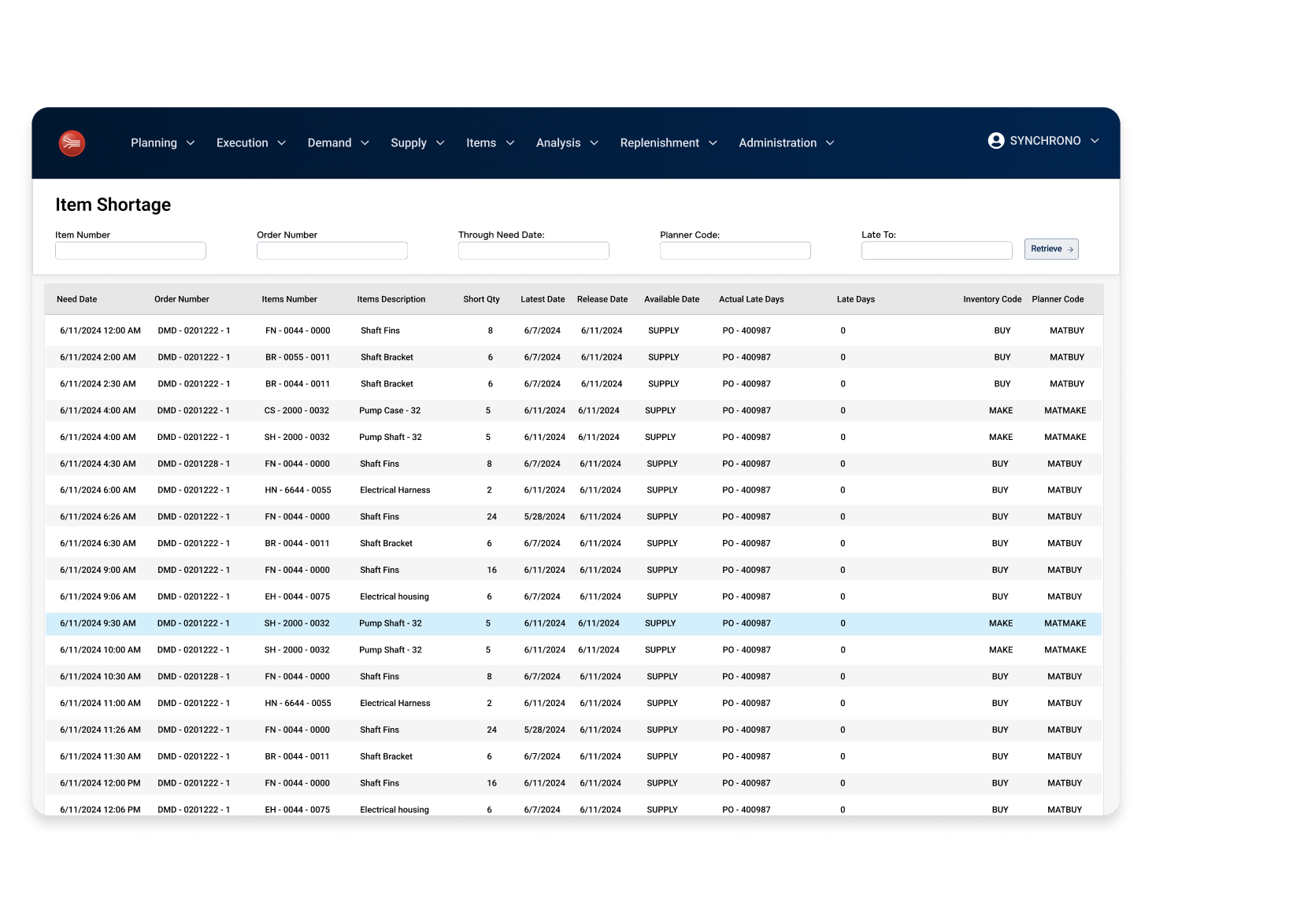

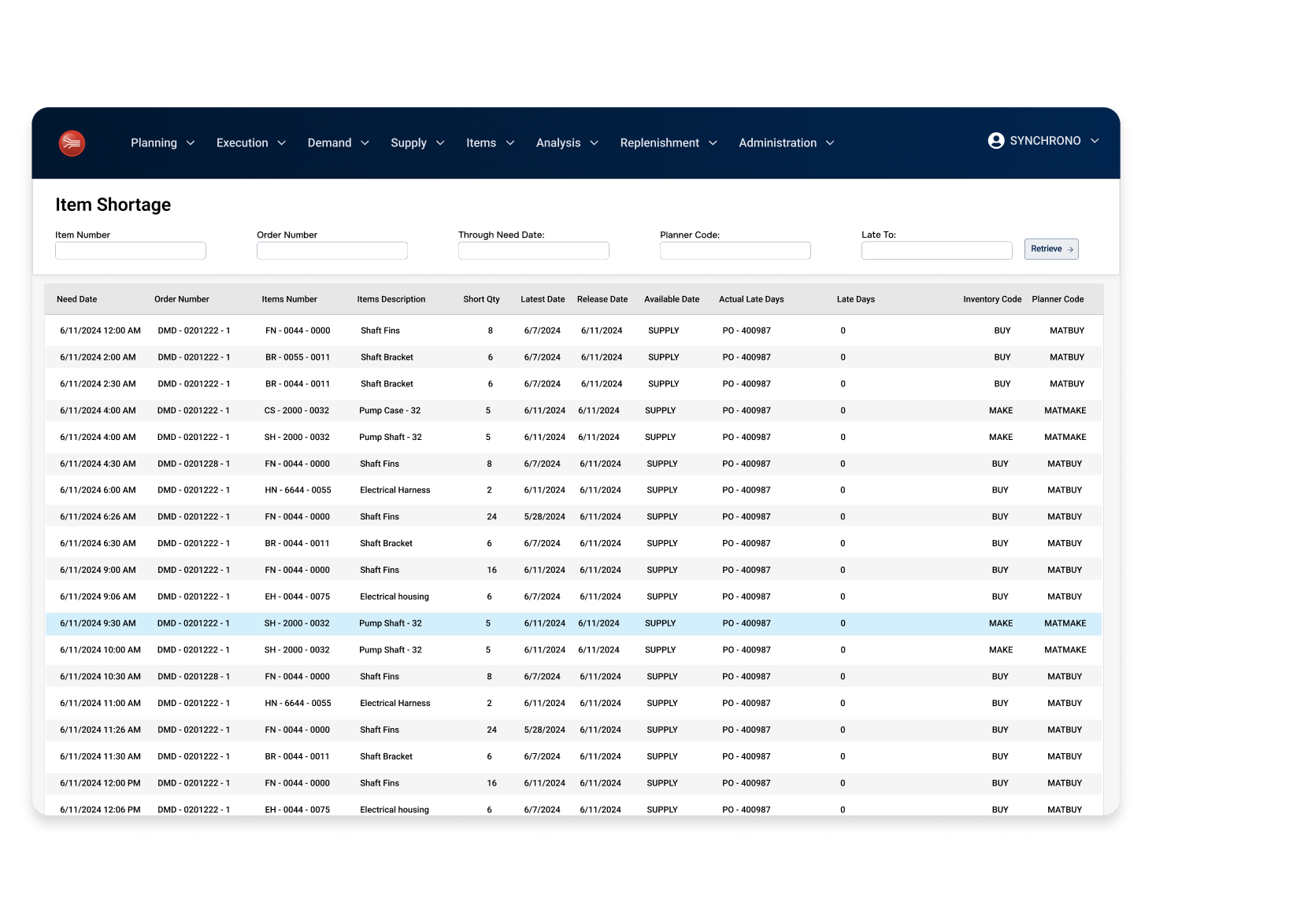

Traditional systems struggle with manufacturing disruptions such as material shortages, machine downtime, rework, and fluctuating customer demand. By the time schedules are rebuilt, conditions on the floor have already changed. This leaves teams reacting to problems instead of proactively managing them.

By adopting advanced planning and scheduling software (APS), discrete manufacturers can align with modern pull-based manufacturing principles and make decisions that keep operations synchronized and competitive.

Key Benefits of APS in Discrete Manufacturing

The ROI of APS is clear: better flow, fewer delays, and greater customer satisfaction. By replacing static methods with dynamic production scheduling, manufacturers can achieve:

- Improved due date performance by aligning schedules with real-world conditions, so customers get accurate delivery promises and reliable fulfillment. This reliability strengthens customer trust and reduces costly penalties associated with late shipments.

- Faster recovery from disruptions as the system adapts instantly when machines go down or material shortages occur, preventing cascading delays. With APS, manufacturers can quickly reallocate resources and keep high-priority orders on track.

- Increased throughput by managing constraints more effectively, keeping work flowing smoothly through bottlenecks that traditionally slow production. By continuously identifying and addressing constraints, teams can achieve higher output without new capital investment.

- Lower overtime and expediting costs by reducing last-minute scrambling, minimizing the need for costly premium labor or emergency shipments. APS ensures resources are planned efficiently, so operations stay balanced even under variable demand.

- Drastically shorter lead-times by optimizing flow through the production process by creating end-to-end synchronization of the entire manufacturing process and the extended supply chain.

Teams can expect measurable improvements in both operational and financial outcomes. From reduced lead times to higher order fulfillment rates, APS directly enhances production scheduling and drives lasting gains in production efficiency.

Learn More →

SyncManufacturing®: Our APS Solution

Not all APS software is created equal. Synchrono® stands apart with SyncManufacturing®, an APS solution designed specifically for discrete manufacturers. Unlike black-box optimizers that generate static schedules, SyncManufacturing® applies pull-based manufacturing and demand-driven planning to continuously synchronize flow.

Key differentiators of the platform include:

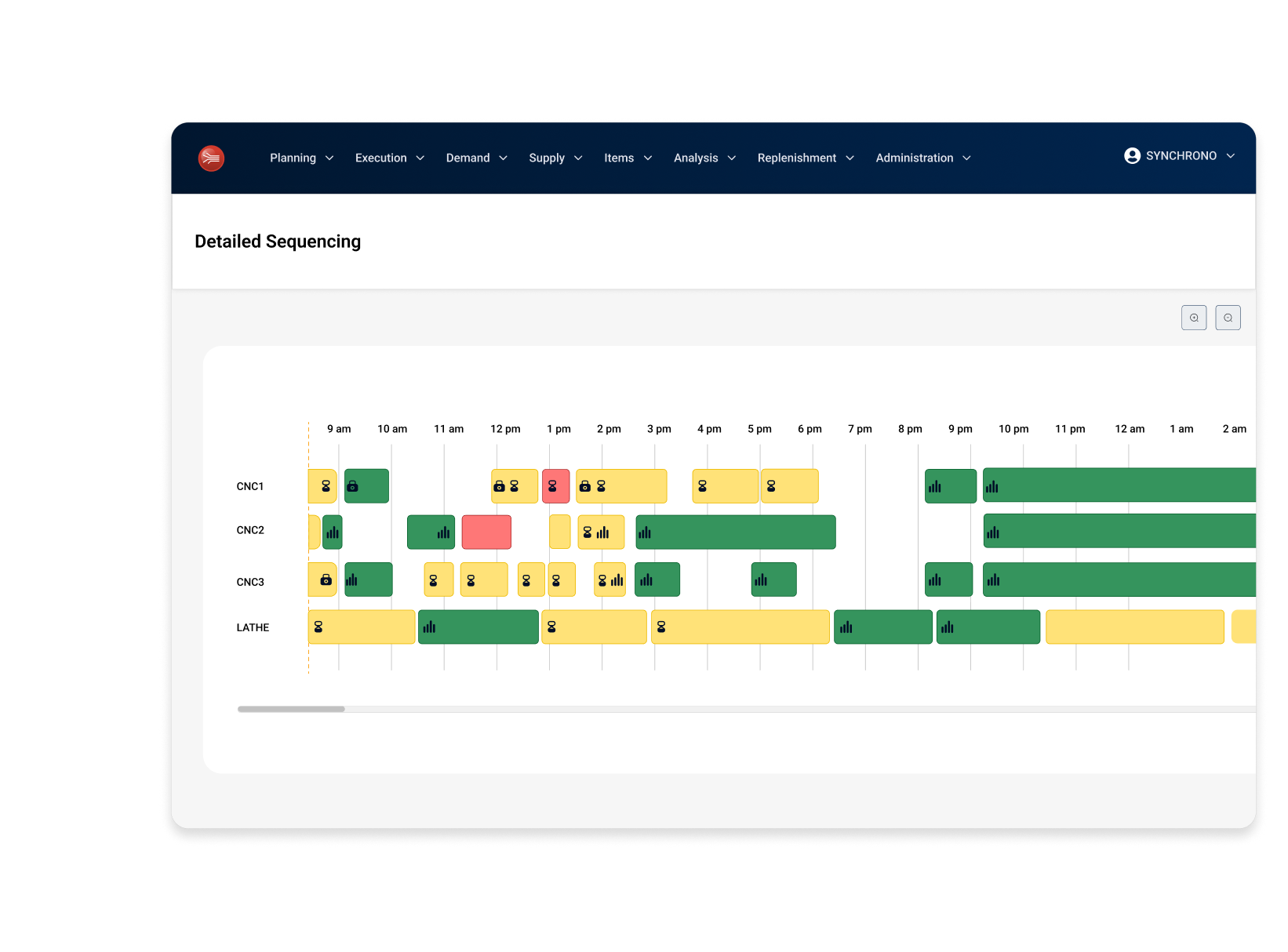

- Finite capacity scheduling to prevent overloading resources and ensure plans are realistic, achievable, and sustainable over time.

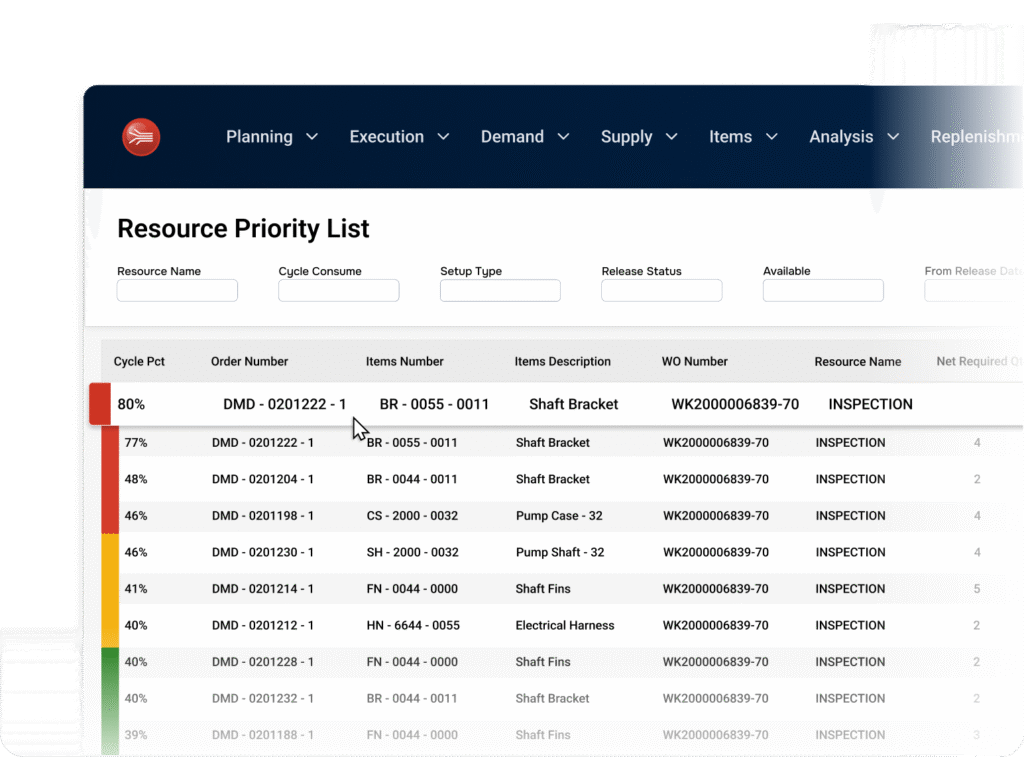

- Lean and Theory of Constraints alignment that targets constraints directly, reducing waste while maximizing throughput and resource efficiency.

- Integration flexibility with ERP and MES systems, enabling smooth adoption without disrupting existing business systems or processes.

- Dynamic production scheduling that automatically adjusts when variability occurs, ensuring teams always work from the most current and accurate plan.

Manufacturers in industries like aerospace and capital equipment have achieved dramatic improvements by deploying SyncManufacturing®. From cutting late orders in half to boosting throughput without new capital investment, our platform delivers measurable results.

Get Started With APS from Synchrono

Modern manufacturers cannot afford to let outdated scheduling tools slow them down. Synchrono® makes it simple to explore how APS can transform your plant. Whether you are evaluating options, looking for integration guidance, or seeking a proven aps solution, our consultative approach ensures you have the resources needed to make an informed decision.

From initial assessments to full implementation, we help tailor the system to your workflows and priorities. With our support, manufacturers gain confidence that their investment in advanced planning and scheduling systems will deliver both immediate and long-term value.

The next step is easy: request a demo and see how Synchrono® can unlock the full potential of your scheduling.

Request a Demo →