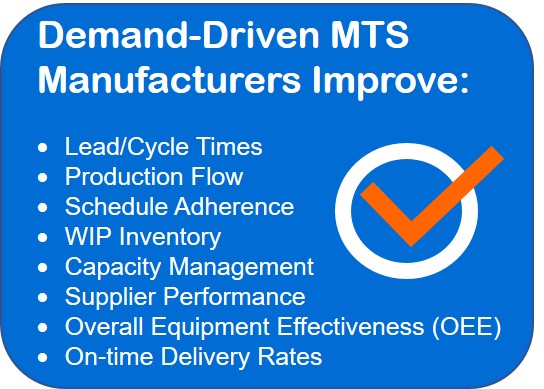

We talk a lot about constraints management in our work with customers who are implementing Demand-Driven Manufacturing (DDM) in their facilities. That’s because constraints management is fundamental for synchronizing the pace of production and keeping the demand (orders) flowing throughout the shop floor. But, our focus is naturally on physical constraints, e.g., that piece of equipment or workstation that is preventing you from delivering on time or offering shorter, more competitive lead times to your customers.

Not Everything is About Production

Those of you who have spent time studying the Theory of Constraints (TOC) in-depth understand that it’s not always all about the production process. Constraints can fall into one of four categories:

![]() Physical – These are the constraints we focus on with technologies like CONLOAD™ that set the pace for production based on the capacity of the physical constraint.

Physical – These are the constraints we focus on with technologies like CONLOAD™ that set the pace for production based on the capacity of the physical constraint.

Policy – These constraints dictate how work is performed. Sometimes you can do something about them (e.g., an old company policy that no longer makes sense), and sometimes you can’t (e.g., a regulation that still might not make sense but needs to be followed anyway).

Paradigm – This is a way of thinking that gets in the way of meeting commitments, such as the COO’s resistance to outsourcing processes to other companies even if they can do it faster, better or cheaper than you can.

Market – Put simply, capacity exceeds demand. Remember, TOC emphasizes throughput (The rate at which the system generates “goal units,” Goldratt) and not productivity.

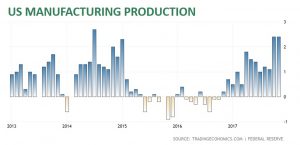

For some manufacturers, the real constraint over the last decade has been their market. Manufacturing production has seen its share of ups and downs in the last ten years. It wasn’t that our facilities couldn’t produce more, many manufacturers just didn’t have the orders to warrant increased production.

Shifting Your Paradigms

Early indications are that many of the market constraints on US manufacturers may be melting away in 2018 through 2020. (Along with a few policy constraints.) Manufacturing GDP is expected to slightly outpace GDP for all industries (2.5%) and grow by 2.8%. (Some analysts are predicting even higher numbers, but like our customers, we prefer to focus on more conservative estimates when doing mid-term forecasting.) The stock market is also at an all-time high, indicating strong investor confidence and more money for investment. Oil prices are expected to remain low, keeping the cost of manufacturing and transportation of goods to market in check.

In other words, it’s time to take your focus off the market constraints you can’t do much about and place it on the constraints that are within your control. If you have outdated policy or paradigm constraints, it’s time to rethink your thinking. If you have physical constraints – leverage them to set the optimal pace for uninterrupted production flow.

Time flies and so do great economies. Don’t let the best market in a decade pass you by without taking advantage of it. If your constraints are physical, here are a few resources that may help:

Video: Manage Manufacturing Constraints and Optimize Production Flow with CONLOAD

White Paper: Metrics That Drive Action

Case Study: GIW Industries