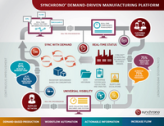

Why Demand-Driven Manufacturing is Focused on Metrics for Action

Driving Continuous Improvement. In Demand-Driven Manufacturing, there is only one measurement that is important to drive performance: Throughput. There are two subordinate measurements: Inventory and Operating Expense. These three measurements cover the gambit of what needs to be measured because they are directly related to customer orders, cash captured inside the organization, and the cash it takes to turn inventory into sales. Demand-driven managers know that having too many metrics