Table of Contents

- What is ERP?

- ERP Limitations

- What is APS and How Does it Fill the Gaps?

- The Benefits of APS

- ERP and APS Integration

- Enhance Your ERP with APS

Enterprise Resource Planning (ERP) systems are often praised as all-in-one solutions for managing business processes. They digitize and automate workflows across an organization, offering a wide range of functionalities under one roof. However, when it comes to addressing the specific complexities of manufacturing—like finite capacity planning or managing labor resources—ERP systems can benefit from additional support. That’s where Advanced Planning and Scheduling (APS) applications come in.

APS software is purpose-built to handle the many challenges manufacturers face, without requiring you to “rip and replace” your current investment in ERP. In this blog, we’ll explore the key differences between ERP and APS systems, how they complement each other, and how APS can help manufacturers overcome planning and scheduling obstacles with greater efficiency and precision than traditional ERP alone.

What is ERP?

To understand how APS systems complement ERP, we must first acknowledge what ERP systems do well. These applications (often a collection of “modules”) are designed to manage and control core business functions, such as inventory, finance, human resources, vendors, customers, and basic operations. They’re great at managing the “master records” for these functions. In the manufacturing world, this would include elements like bills of material, pricing schedules, contract details, etc. They also deal with the “numbers,” e.g., how much material or finished inventory is on hand, what components are on order and when they are expected to arrive, what a vendor’s average lead time is, and so on.

Instead of duplicating what ERP systems do well, APS software leverages these functions and builds upon them to handle the things most ERP systems do poorly in a manufacturing environment.

ERP Limitations

ERP systems are typically oriented around business process logic, which doesn’t always map to the unpredictable behavior of equipment and material flows in a complex manufacturing environment. This disconnect can make it difficult for production schedules to reflect factory-floor realities. Here are a few of the limitations that create particularly painful headaches for manufacturers.

Infinite resource capacity assumed – ERP systems typically assume infinite resource capacity (including people and equipment), leading to a host of issues such as unrealistic delivery schedules, poor resource utilization, and on-going shop floor bottlenecks. Precise forward (or backward) scheduling tied to actual resource constraints often requires significant manual intervention.

Limited ability to handle disruptions – Agility is critical in today’s manufacturing environments, but ERP systems were built with a decoupling between modules (ie. purchasing, production, and sales) that makes it difficult to understand and respond to disruptive events. Complex manufacturing often requires a web of production resources, spanning multiple production lines and facilities. A bottleneck or delay in one area can have a ripple effect on the entire system. Even those ERP systems known for their manufacturing capabilities lack the ability to respond to operational or supply chain disruptions and dynamically adjust schedules throughout the enterprise.

Misalignment between supply and demand – As noted already, traditional ERP platforms are excellent for managing core business functions. However, their approach to operational processes is normally standard lead times an daily buckets instead of continuous flow and synchronization between supply and demand signals. This results in misaligned replenishment cycles and fragmented planning. Furthermore, most ERP systems decouple supply from demand at every level in the multi-level bill of materials, making it even more challenging to synchronize production stages with real-time demand.

Customization and adaptability limitations – ERP vendors often promote the customizability of their systems, but the intricate nature of manufacturing (multi-site, multi-product, variable batch sizes) makes it difficult for a single ERP configuration to handle all scenarios without extensive tailoring. This forces manufacturers to adapt their workflows to the software rather than the other way around. Furthermore, custom changes can be expensive, slow to implement, and complicate future upgrades.

What is APS and How Does it Fill the Gaps?

As we touched on above, most ERP systems treat resources as infinite. They may look at current and future inventory availability through materials requirements planning, but people and equipment are seen as inexhaustible. Production lead times are static estimates, typically stored in the master data file. Hence, the Master Production Schedule (MPS) produced by ERP is at best an estimate of what might be produced and by when under optimal conditions – which they rarely are.

Conversely, APS systems tie production to real-time, real-world data, including actual resource constraints. The production schedules produced by APS reflect operational realities and are far more realistic than the static guesses produced by ERP. When the inevitable disruptions happen and schedules are thrown off, APS can dynamically reschedule operations throughout the enterprise, optimizing resource utilization and safeguarding throughput.

The Benefits of APS

Many manufacturers who come to us for help do so because they are missing core targets and KPIs like on-time deliveries, inventory turns, cycle time, equipment utilization, and more. Often, they were hoping their ERP system would help them achieve their goals. Unfortunately, regardless of how cleverly they are marketed, ERP systems were never designed to do what APS software can do.

Having the kind of clear execution plan that only APS can provide leads to several enterprise-wide improvements, including:

- Clear direction – Everyone knows what to work on and when to work on it.

- Less idle time – Factory workflow is optimized so employees and resources aren’t waiting for work to show up.

- Improved equipment utilization – Manual production scheduling can lead to pile-ups behind some equipment while other resources sit idle. APS takes advantage of available capacity to optimize equipment utilization.

- Lower cycle times/faster throughput – Optimizing workflow also speeds up operations lowering cycle times and improving throughout performance.

- Better constraints management – Some APS systems, like SyncManufacturing, can help identify the real shop floor bottlenecks so you can address them to further improve throughput and lower cycle times.

- Reduce lead times – Lower cycle times and increased velocity naturally lead to lower lead times. For example, this SyncManufacturing customer reduced lead times from 3-4 weeks to less than 5 days.

- Improved on-time delivery performance – Since APS uses finite capacity planning, production schedules are more realistic.

- Build customer trust – Since production schedules are more realistic, so are capable to promise dates.

- Less expediting – More realistic production schedules also mean less expediting, which can lower production costs, not to mention stress levels.

- Synchronize production – APS aligns the multi-level BOM structure, overcoming the decoupling effects of ERP / MRP.

- Lower inventory levels – By aligning procurement and WIP production to demand, many manufacturers are able to dramatically lower inventory levels. For example, this SyncManufacturing customer reduced WIP by 15% in the first three months after implementing APS.

See our customer case studies to learn more about how manufacturers are achieving these benefits by implementing SyncManufacturing.

ERP and APS Integration

As we’ve discussed, ERP systems excel at managing master data files across the business, from production to inventory to finance. This reliable and accurate data source is essential for the analyses that APS performs, so a solid ERP system that provides reliable data is still essential. APS leverages and supplements that data, providing insights across the enterprise and direction to production.

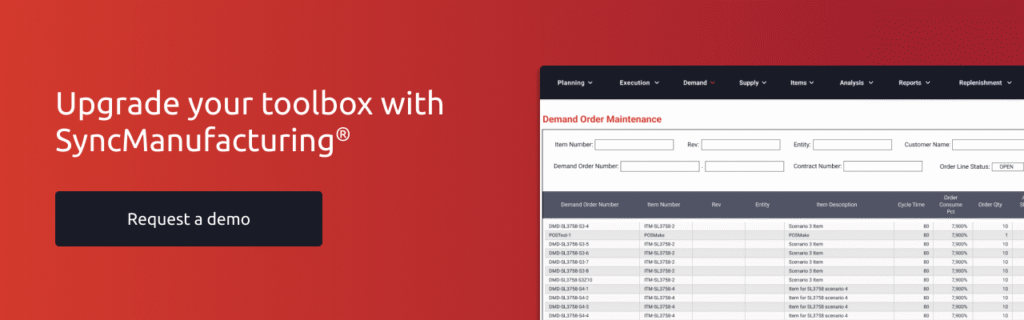

Synchrono currently integrates with a wide variety of ERP systems. Some of the most common ERP systems SyncManufacturing integrates with include SAP, Microsoft D365, Infor, Epicore, Oracle, Costpoint, and many more.

Enhance Your ERP with APS

If you’re aiming to elevate your planning, scheduling, and execution capabilities, it’s time to look beyond what traditional ERP systems alone can offer. Integrating APS with ERP allows you to fill critical gaps—optimizing production schedules, improving resource utilization, and increasing agility across your operations. APS brings the precision and flexibility needed to respond to real-world manufacturing complexities, enhancing your ERP investment with real-time insights and more dynamic, achievable plans.

Are you ready to take control of your manufacturing operations? Take the next step by setting up a demo of SyncManufacturing® and explore how our APS system can pick up where your ERP system leaves off.