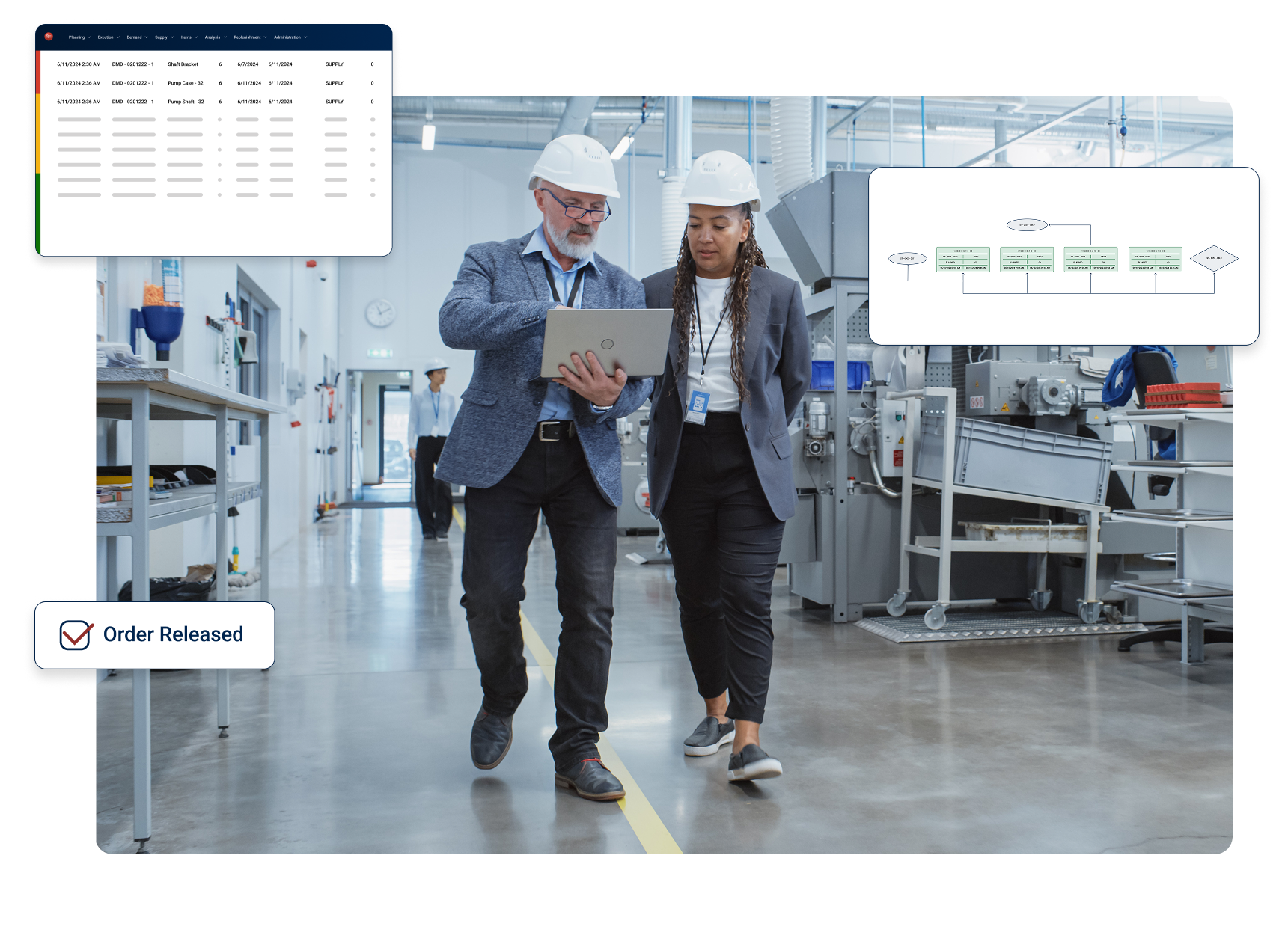

Advanced Planning and Scheduling for Automotive Manufacturers

In a fast-moving, high-stakes environment like the automotive supply chain, delivering on promises isn’t just a best practice – it’s a competitive necessity. Advanced Planning and Scheduling Software (APS) from Synchrono® helps automotive parts manufacturers overcome resource constraints, adapt to fluctuating priorities, and handle unforseen delays with confidence.

How APS Works

SyncManufacturing from Synchrono integrates with your existing systems to set the foundation for smart planning and scheduling. Scheduling aligns production to material availability and capacity by accounting for real-time equipment and tool constraints. Leveraging live data, production schedules are adjusted to adapt to unanticipated delays and fluctuating priorities. With one click, adjusted schedules are sent throughout the organization, keeping everyone aligned to the production schedule and priorities.

Key Benefits for Automotive Parts Manufacturers

With Just-In-Time (JIT) replenishment becoming a cornerstone of the automotive manufacturing industry, parts suppliers are often under intense pressure to meet their delivery commitments. SyncManufacturing from Synchrono helps automotive manufacturers:

Enable Sales

Provide your sales team with real-time access to accurate capable-to-promise dates that account for inventory and resource constraints. SyncManufacturing gives sales the insights they need to avoid overcommitting factory resources and build customer trust. With increased visibility, production supervisors spend less time negotiating delivery dates and expediting orders to meet customer promises.

Facilitate Partnerships

As complex as the automotive manufacturing supply chain can be, collaboration is essential. SyncManufacturing helps foster relationships with OEMs, technology providers, and other suppliers through transparent, standardized planning processes.

Optimize Resource Utilization

SyncManufacturing leverages finite capacity planning algorithms to align production to factory capacity. Improved resource utilization has helped our customers slash lead times by as much as 75% and improve on-time deliveries from 50% to 98%.

Stay Agile & Aligned

SyncManufacturing allows you to easily adapt to supply chain disruptions and unforeseen production delays with real-time scheduling adjustments. Schedule changes can be easily disseminated throughout the organization so everyone is working from the same plan.

Stay Lean & Lower Costs

Lower inventory costs and waste by synchronizing production schedules with actual demand and available capacity. SyncManufacturing allows you to focus on improving throughput, not just “staying busy.”

Automotive Supply Clients

Club Car is the world’s largest manufacturer of small-wheel, zero-emissions electric vehicles

Power Up Your Performance

SyncAlert®

Monitor and manage production performance from your mobile device. Receive alerts when issues need to be addressed and assign action items to the appropriate personnel.

SyncKanban®

The ultimate in lean replenishment techniques, our eKanban application aligns replenishment signals to actual demand. SyncKanban® can even dramatically resize your Kanban loops.

SyncView®

Have targeted KPIs? SyncView® provides a real-time, visual representation of factory performance. Dashboards can be defined by user type for targeted insights and improved focus.

Is Your Organization Firing on All Cylinders?

Digital transformation requires manufacturers to break down the silos within their organization so that every department and every team is working together toward a common goal. If you’re ready to transform your organization into a well-oiled machine, reach out to us today or request a live demo.