Advanced Planning and Scheduling for Capital Equipment Manufacturing

SyncManufacturing® is a vital tool for capital and industrial equipment manufacturers looking to streamline production processes and ensure on-time delivery while staying within budget. Our Advanced Planning and Scheduling (APS) software provides real-time visibility into production schedules, enabling planners to anticipate bottlenecks, optimize workflows, and dynamically adjust plans as priorities shift or unexpected disruptions occur.

Production Scheduling That Works the Way You Do

SyncManufacturing from Synchrono integrates with your existing systems to set the foundation for smart planning and scheduling. Dynamic scheduling leverages live data to adjust production schedules to unanticipated delays and fluctuating priorities. With one click, adjusted schedules are shared throughout the organization, keeping everyone aligned to the current schedule and top priorities.

Increase Velocity

Using finite capacity production scheduling, SyncManufacturing helps ensure resources are not overbooked, preventing work center bottlenecks that can impede production flow. Dynamic scheduling also helps planners more accurately predict when a product or job will be completed. This predictability enables better coordination between successive stages of production, ensuring that all resources within the value stream are aligned with one another and ultimately to the customer demand. Maintaining a steady flow through the factory also helps decrease cycle times.

Enable Sales & Build Customer Confidence

With real-time access to accurate capable-to-promise dates, SyncManufacturing gives sales the insights they need to avoid overcommitting factory resources and build customer trust. With increased visibility, production supervisors also spend less time negotiating delivery dates with the sales team and expediting orders to meet customer promises.

Manage Supply Chain Volatility

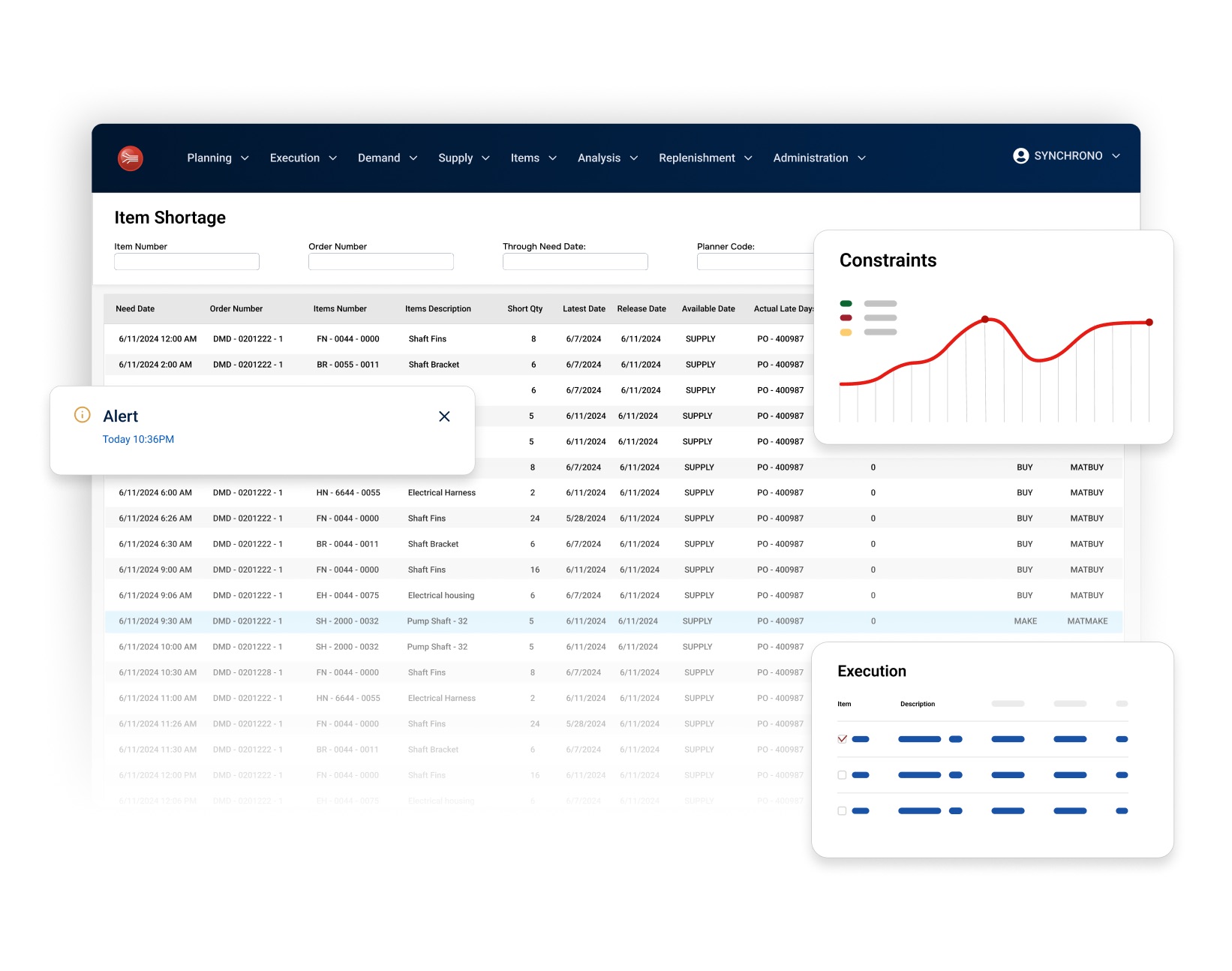

Lengthy cycle times in capital equipment manufacturing offer plenty of opportunity for supply chain disruptions to throw off production schedules. Integrating SyncManufacturing with existing ERP systems and other supply chain management tools helps capital equipment manufacturers stay agile in the face of fluctuating tariff rates, supplier costs, and material availability. Real-time visibility into supply and demand, inventory levels, and production capacity supports strategic decision-making that benefits the bottom line and helps ensure your team never misses a beat.

Improve Workforce Utilization

Talent shortages, high wages, and fast turnover can make managing today’s production workforce challenging. SyncManufacturing’s finite capacity scheduling capabilities include workforce constraints. Advanced algorithms and real-time data ensure labor resources are allocated effectively, aligning workforce capabilities with production demand to reduce idle time, ensure smoother operations, and improve overall productivity.

Minimize Downtime

Capital equipment manufacturers understand the importance of regular maintenance for industrial equipment. SyncManufacturing helps align preventative maintenance schedules to production priorities. Of course, equipment malfunctions don’t always follow the planned maintenance schedule, so our APS software allows planners to minimize the impact of unplanned downtime by quickly rerouting and realigning resources to ensure work keeps flowing through the factory.

Johnstech provides top-performing test contractors and services, delivering unmatched electrical and mechanical reliability. Trusted by global semiconductor manufacturers and test houses, their solutions ensure accurate, stable testing across diverse applications.

Improve On-Time Delivery Performance

SyncManufacturing helps capital equipment manufacturers ensure everyone is working on the most critical activities first.

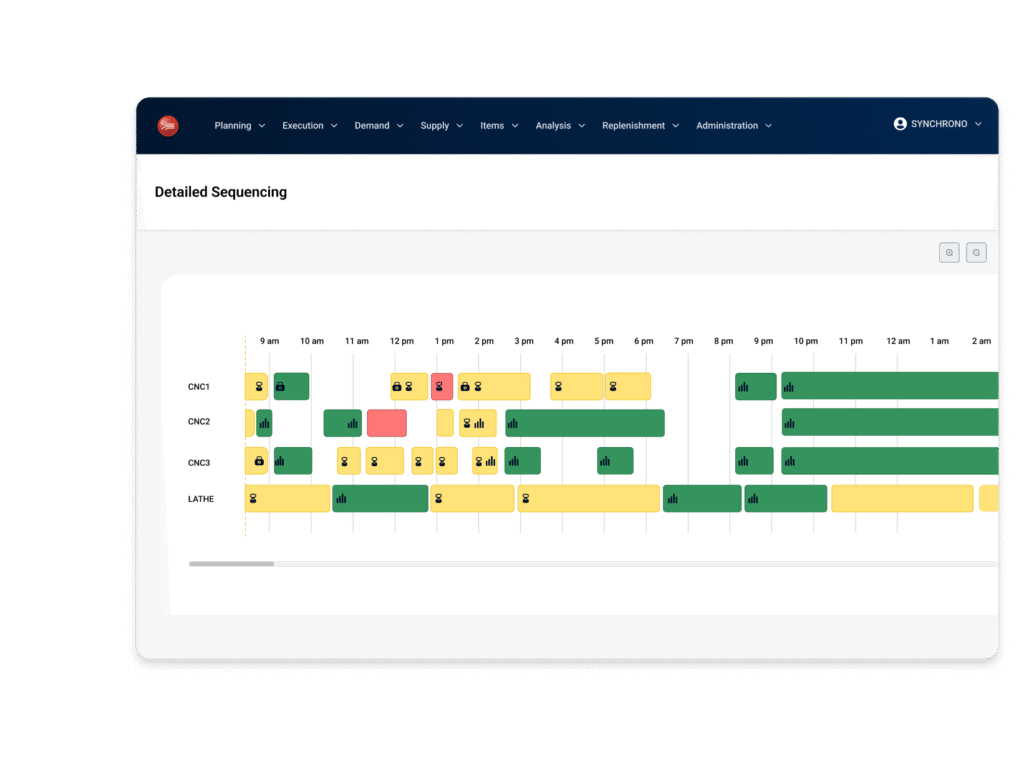

- Work order sequencing ensures that production tasks are scheduled based on priority, capacity, and dependencies to minimize delays created by bottlenecks or mismanaged resources.

- Visual scheduling boards provide a graphical representation of scheduled operations against finite machine and work center capacity, allowing planners to identify bottlenecks and adjust priorities.

- Color coding, filters, and drag-and-drop functionality make it easier to locate and reschedule operations, contributing to faster decision-making and better alignment with delivery timelines.

- Real-time alerts enable proactive troubleshooting, ensuring that problems are addressed before they impact delivery schedules.

Power Up Your Performance

Give your continuous improvement initiatives the boost they need with these SyncManufacturing add-ons.

SyncAlert®

Monitor and manage production performance from your mobile device. Receive alerts when issues need to be addressed and assign action items to the appropriate personnel.

SyncKanban®

The ultimate in lean replenishment techniques, our eKanban application aligns replenishment signals to actual demand. SyncKanban® can even dramatically resize your Kanban loops.

SyncView®

Have targeted KPIs? SyncView® provides a real-time, visual representation of factory performance. Dashboards can be defined by user type for targeted insights and improved focus.

Does Your Organization Run Like A Well-Oiled Machine?

Shouldn’t your organization function as well as the equipment you manufacture? Making that happen often requires breaking down silos within the organization so that every department and every team can work together toward a common goal. Advanced Production and Scheduling software from Synchrono can help turn that dream into a reality. So, if you’re ready to transform your organization into the highly calibrated, profit-producing engine it was meant to be, reach out to us today or request a live demo.