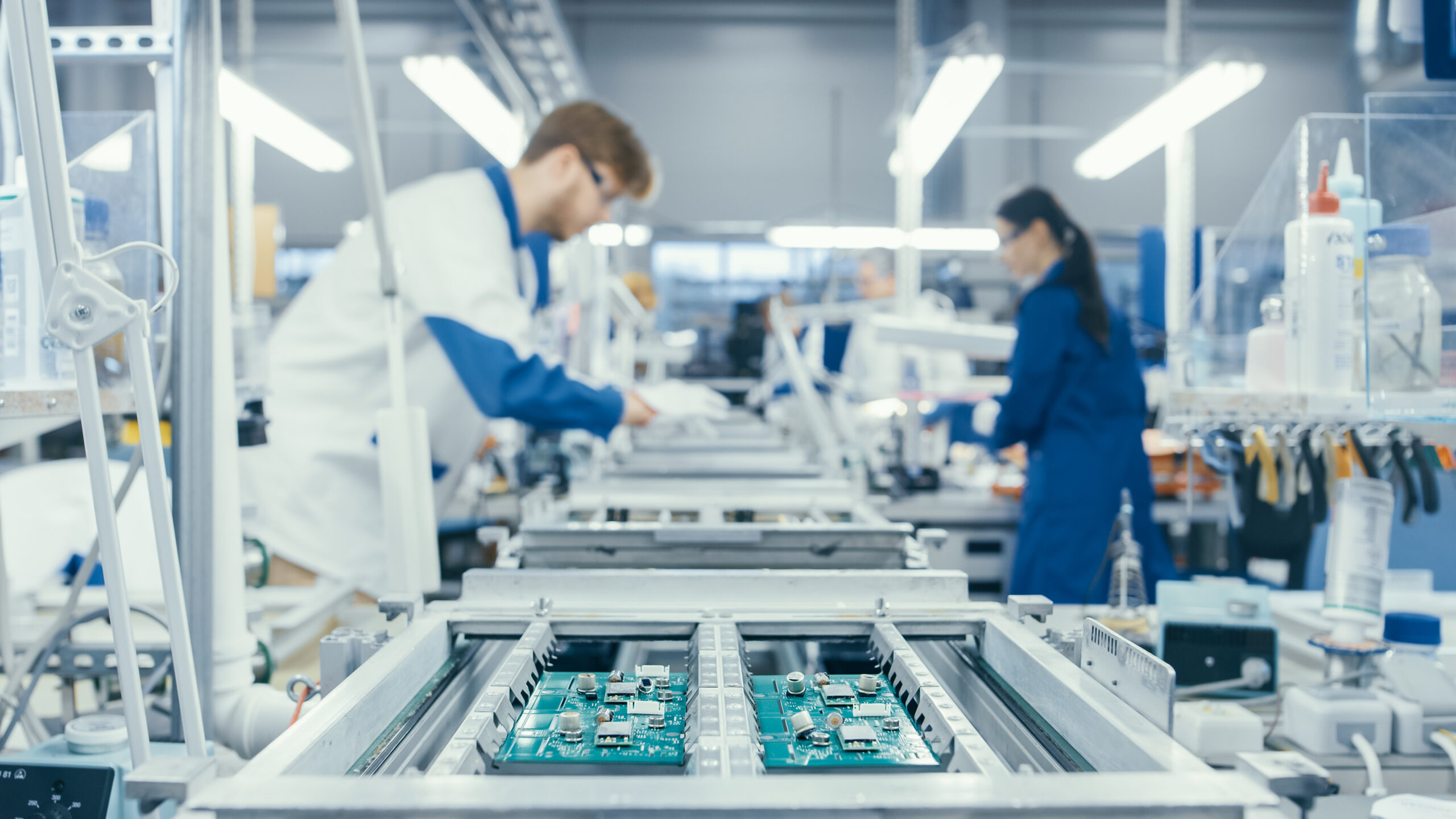

Advanced Planning and Scheduling for Electronics Manufacturing

SyncManufacturing® from Synchrono transforms the way electronics manufacturers operate by smoothing the path toward leaner, more agile operations. Our Advanced Planning and Scheduling (APS) software is designed with the complex, dynamic manufacturing environment in mind. With a suite of advanced, yet easy-to-use features, SyncManufacturing enables electronics manufacturers to align their production processes with demand, improve resource utilization, increase throughput, and more.

What is APS Software?

APS systems help production planners and schedulers optimize production to meet demand and improve manufacturing efficiency by aligning production to actual demand and resource availability. Unlike traditional Material Requirements Planning (MRP) solutions, APS systems account for capacity constraints (also known as finite capacity planning or scheduling), inventory availability, and lead times. By synchronizing materials, capacity, and labor with demand, APS helps improve resource utilization and ensure equipment and people are effectively deployed to meet delivery commitments while minimizing waste and costs.

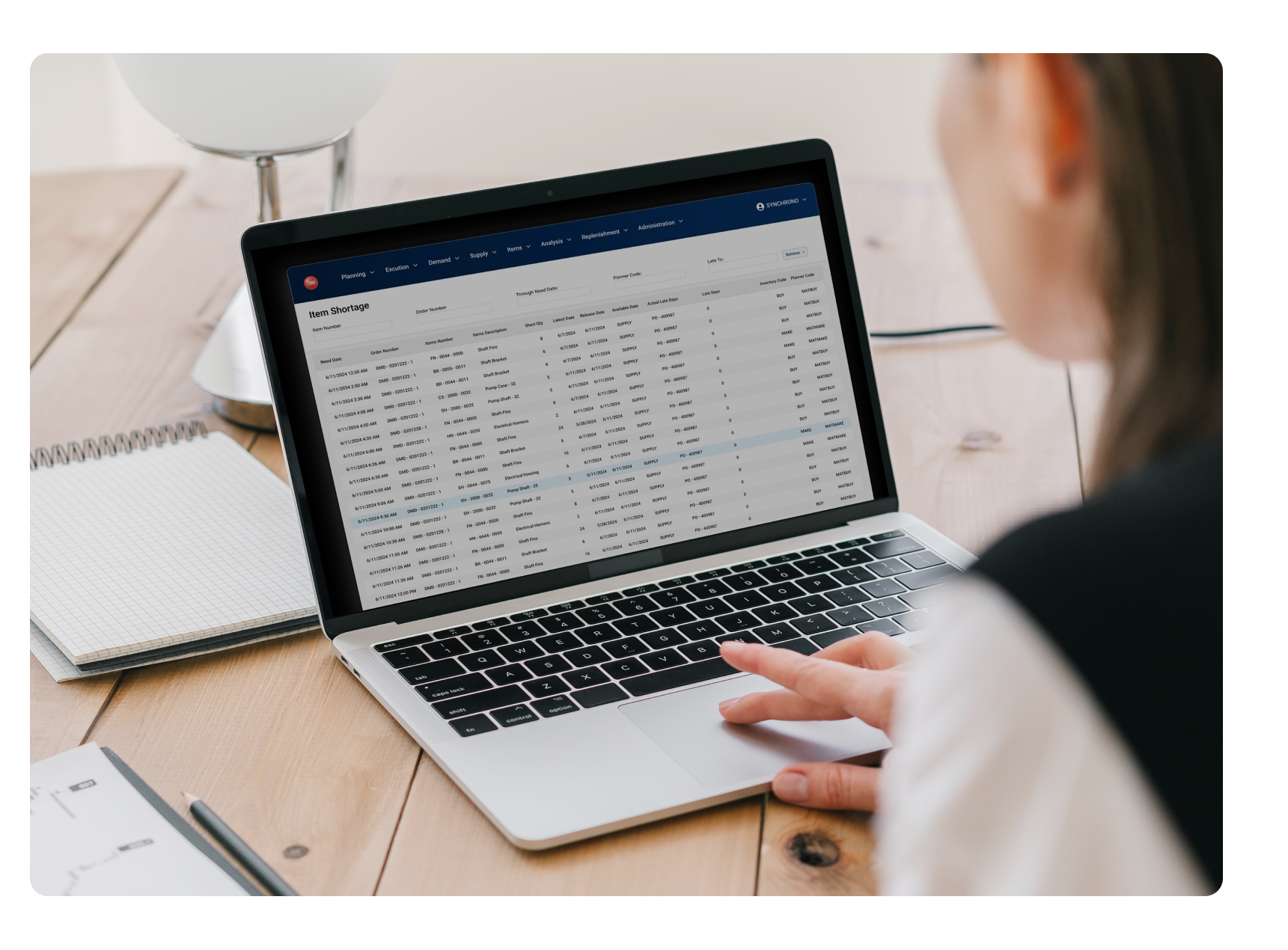

Production Scheduling That Works the Way You Do

SyncManufacturing integrates with your existing systems so you don’t need to resort to custom-built (and hard-to-maintain) spreadsheets or manual calculations. Leveraging live data from your current systems (MRP, Sales Orders, Inventory Management, etc.) SyncManufacturing automatically aligns resource allocations and production schedules to demand and provides you with insights and operations management tools that traditional ERP systems just don’t offer.

Be Agile

These days, production schedules can be impacted by any number of external events. While some factors, such as materials shortages, tariffs, and trade restrictions, may be outside your control, APS software can help you remain agile and adaptive. When an alternate source is used, SyncManufacturing automatically updates production schedules to reflect new lead times. This reduces idle time waiting for components that have yet to arrive and decreases cycle times by keeping work flowing smoothly through the factory.

Get Lean

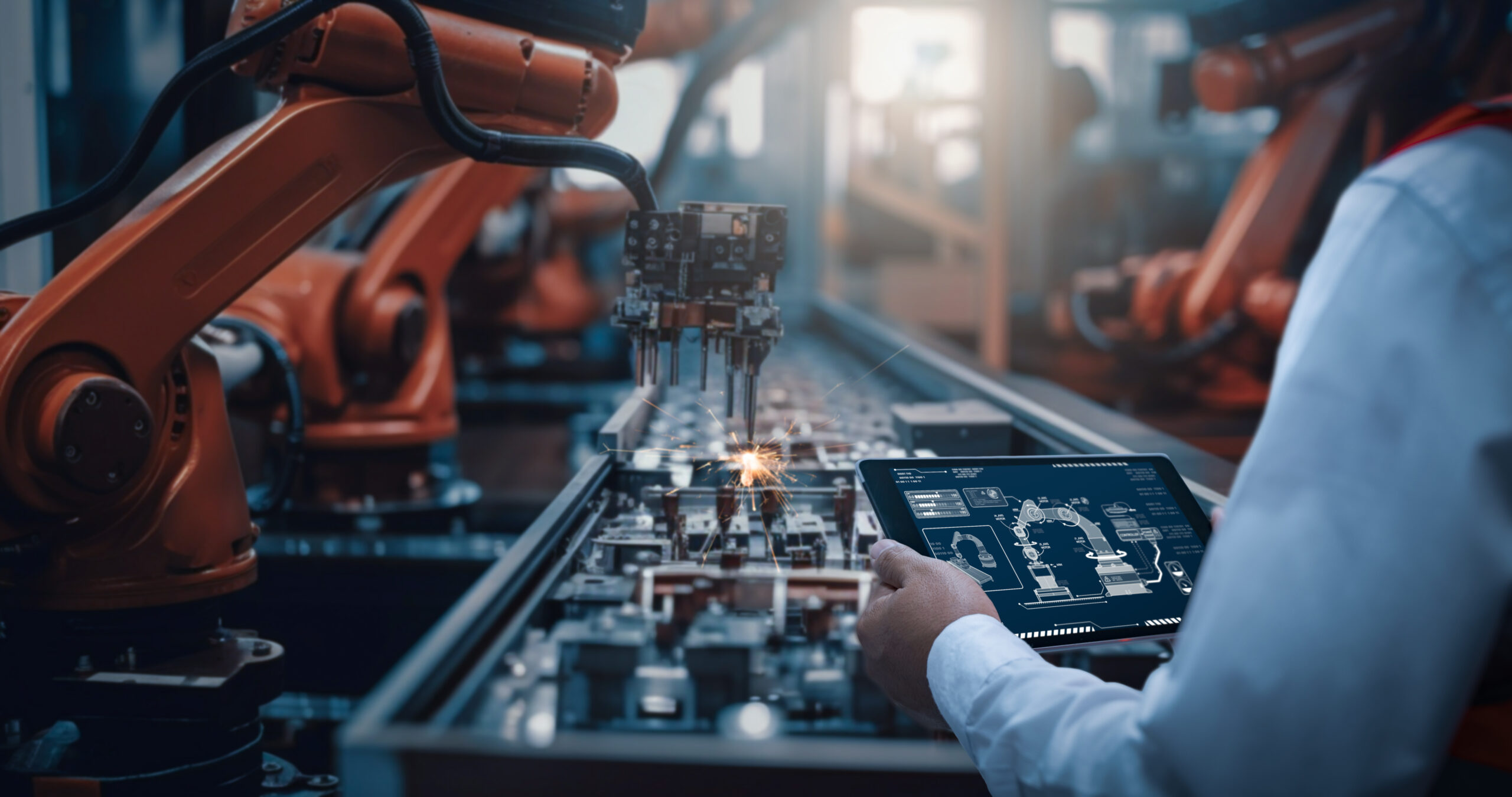

Optimizing resource utilization is critical to minimizing waste. Using finite capacity production scheduling, SyncManufacturing helps ensure resources are not overbooked, preventing work center bottlenecks that can impede production flow. If production is delayed, dynamic scheduling can quickly readjust schedules to work around the challenge to minimize idle time while focusing on throughput. Our add-on solution, SyncKanban, can help you take your lean initiative to the next level by right-sizing inventory with real-time demand signals and other powerful lean management tools.

Increase Throughput

The SyncManufacturing adaptive scheduling algorithms manage production from a value-stream perspective. Our patented continuous-load methodology CONLOAD™ controls when work is released to the shop floor and determines the overall pace of the manufacturing process. CONLOAD™ embodies the theory of constraints approach to lean manufacturing by focusing on constraints to set the pace and by gating work into production based on actual performance and the capacity of the shop floor. Demand signals are delivered upstream to work centers to produce only when downstream control points – or customers – indicate.

Enable Sales

Short product lifecycles can create opportunities, but meeting delivery dates can also make or break the company’s reputation. SyncManufacturing gives your sales team real-time access to accurate capable-to-promise dates, so they can build customer trust and take advantage of market dynamics. With increased visibility, production schedulers also spend less time negotiating delivery dates with the sales team and expediting orders to meet customer promises.

Improve On-Time Deliveries

SyncManufacturing’s visual scheduling boards provide a graphical representation of scheduled operations against finite machine and work center capacity, allowing planners to identify bottlenecks and adjust priorities. Color coding, filters, and drag-and-drop functionality make it easier to locate and reschedule operations, contributing to faster decision-making and better alignment with delivery timelines.

Power Up Your Performance

Give your continuous improvement initiatives the boost they need with these SycManufacturing add-ons.

eKanban Helps Instrumentation Manufacturer Hit KPIs

Leveraging the Synchrono eKanban system alongside APS helped this instrumentation manufacturer coordinate inventory management and production across multiple sites for substantial improvements in several key metrics.

- 51% reduction in inventory

- 91% improvement in inventory turns

- 83% drop in lead times

- 29-43% reduction in inventory

- 55% reduction in inventory carrying costs

Synchronize Your Operations with SyncManufacturing

Manufacturing optimization requires breaking down silos within the organization so that every department and every team can work together toward a common goal. Advanced Production and Scheduling software from Synchrono can help turn that dream into a reality. So, if you’re ready to transform your organization into the highly calibrated, profit-producing engine it was meant to be, reach out to us today or request a live demo.