Industrial Internet of Things

Building manufacturing intelligence through a fully connected enterprise. The Industrial Internet of Things (known as IIoT) has been a dominant theme among both industry and personal technology trends lately. Envisioning an IoT-enabled, fully connected industrial environment – like a manufacturer’s factory floor – is very enticing. Imagine that machines and tools are networked and sending data instantly as production happens and customer orders progress, giving up-to-the-second feedback on status, environmental conditions, and machine readings. But what happens to all of the data being collected?

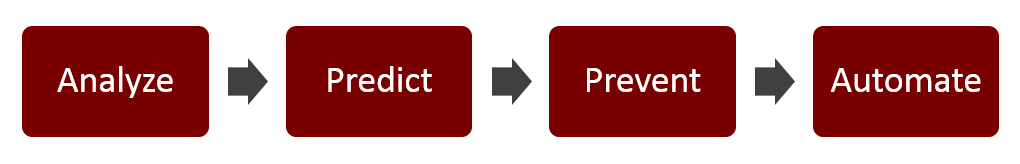

IIoT is only the first step in realizing true manufacturing intelligence. A connected manufacturing environment lays the framework for the utility of collecting data. To realize true business transformation, a solution should go beyond data collection by enabling integration and aggregation, to drive manufacturers to:

Figure 1: The Data Action Maturity Model

SyncOperations software, powered by Savigent, is a proven industry solution that goes beyond the IoT and turns a manufacturing environment into a data-empowered enterprise primed for customer satisfaction and growth. While some applications only fulfill a part of the Data Action Maturity Model, SyncOperations does it all. Built upon a powerful integration platform, SyncOperations enables both machine connectivity as well as application and enterprise software integration.

Analyze – Machine and application data is aggregated into contextualized, usable information within the SyncOperations analysis tool called Information Model Explorer. Full production diagnostics are achieved by putting all relevant data into the hands of the engineers, who are able to visualize and evaluate all conditions and parameters down to the fraction of a second through dynamic charts and graphs.

Predict – Patterns in data are used to predict manufacturing results, which fuels an organization to understand prime performance conditions.

Prevent – Understanding the data behind a manufacturing system enables meaningful corrective actions to be taken, driving smarter decisions on preventative maintenance and minimizing downtime.

Automate – Using the same collected data, SyncOperations software can execute automated workflows, which enforces standard operating procedures and consistent action.

SyncOperations delivers a complete IIoT vision that goes beyond just connectivity. Through SyncOperations software, a single thread of data is transformed into valuable information providing powerful manufacturing and business results.

See for yourself what SyncOperations and the other solutions in the Synchrono® Demand Driven Manufacturing Platform can do for your organization – request a demo!