Manufacturing Production Software for Synchronized Operations

Synchrono® delivers modern manufacturing production software designed to optimize efficiency, streamline operations, and keep production flow synchronized from end to end. Built with advanced planning and scheduling at its core, our solutions provide manufacturers with the visibility and control needed to meet today’s complex demands.

Key differentiators of the Synchrono® platform include:

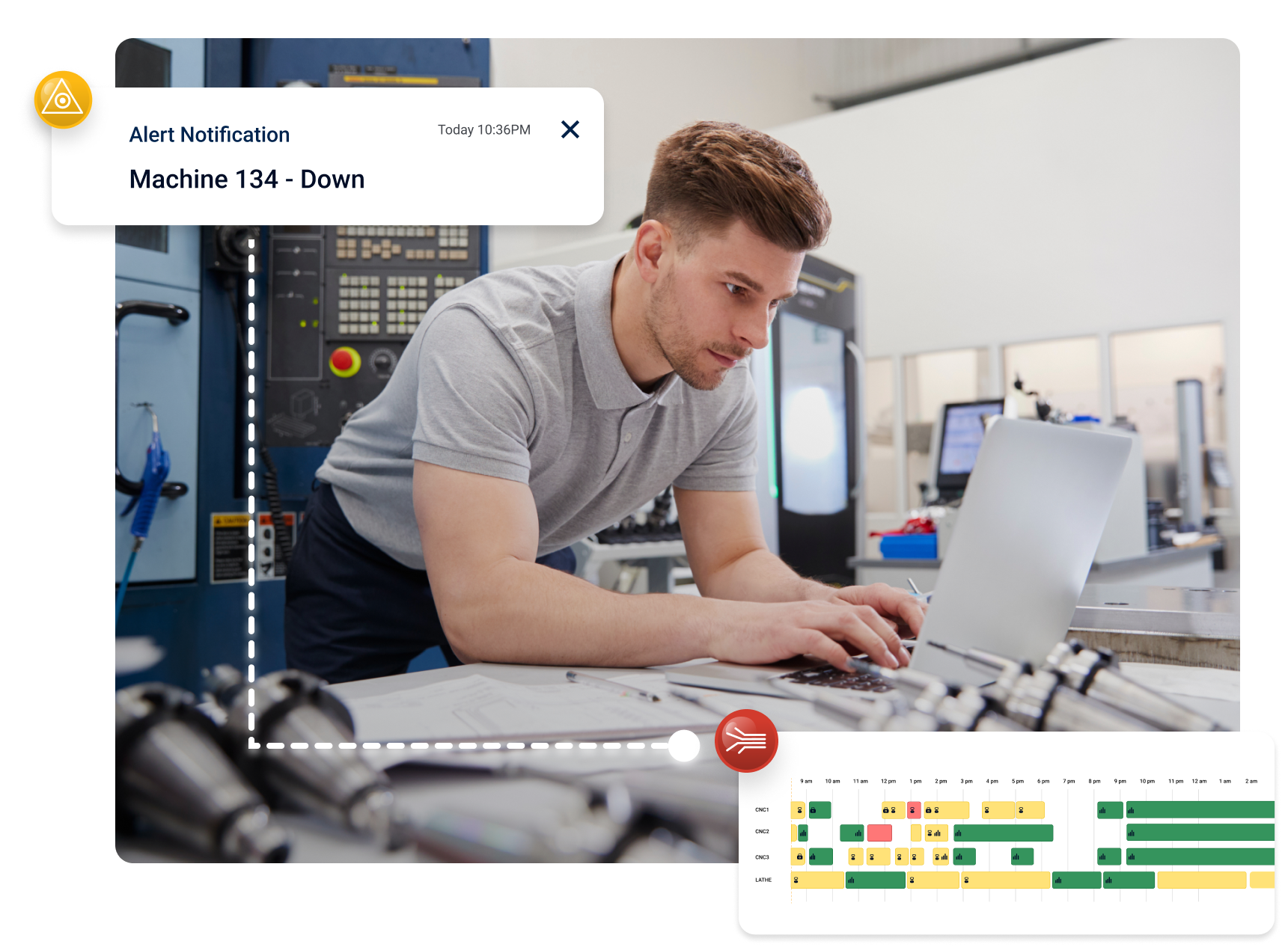

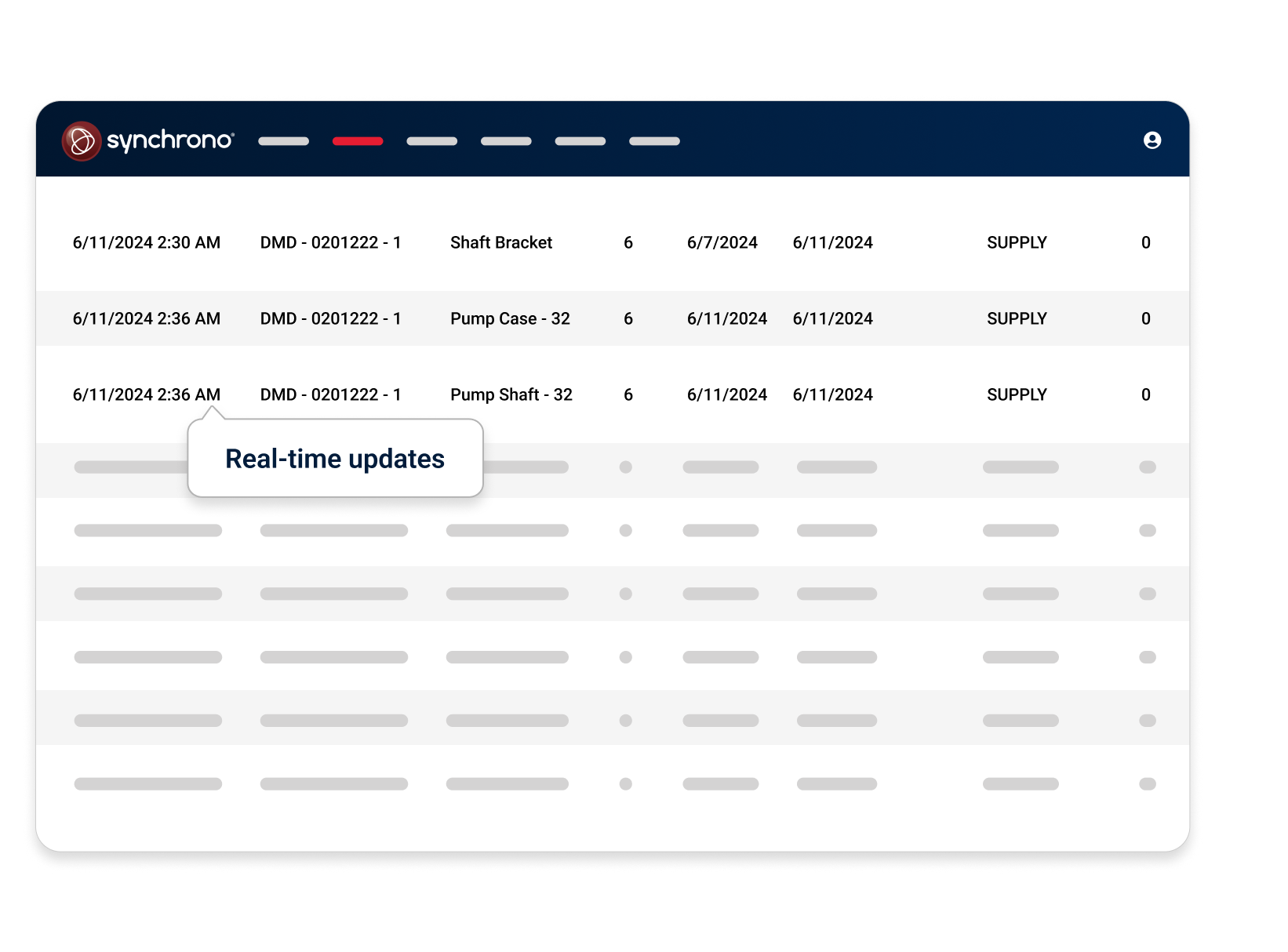

- Real-time updates that connect people, machines, and processes for instant alignment across the factory.

- Constraint-based planning that ensures schedules are realistic, achievable, and optimized for throughput.

- Integration flexibility with ERP and other enterprise systems, creating a unified digital ecosystem.

With Synchrono®, manufacturers gain the tools to increase throughput, reduce waste, and deliver on time—even in high-variability environments.

Designed With Real Manufacturing Challenges in Mind

Synchrono® solutions are built by manufacturing experts, for manufacturers. With more than 25 years of APS leadership we understand the realities of managing complex production environments where every order, machine, and material matters.

Our manufacturing production software is tailored to address challenges such as:

- Custom assemblies that require flexible scheduling and rapid changeovers.

- Multi-site production networks where visibility across facilities is essential.

- Regulated industries like medical devices or aerospace, where compliance and traceability are critical.

- High-mix operations that depend on adaptability and lean workflows.

For example, aerospace manufacturers use Synchrono® to align production scheduling software with regulatory checkpoints, ensuring compliance without delays. Capital equipment manufacturers manage complex processes while keeping teams on track with real-time manufacturing software. In both cases, our tools connect planning and scheduling to execution, helping companies achieve key KPIs like shorter lead times, improved on-time delivery, and higher throughput.

Our approach is rooted in demand-driven manufacturing and pull-based strategies. By shifting focus from forecast-driven plans to actual demand signals, manufacturers gain agility, reduce inventory, and keep flow synchronized with customer needs. Our ability to adapt across industries means even the most diverse companies with the highest variety of manufacturing environments can achieve operational consistency along with strategic flexibility to scale and evolve with market shifts.

Built to Integrate with Your Entire Manufacturing Tech Stack

Modern manufacturers rely on a wide range of digital tools to keep operations running. Synchrono® ensures that our manufacturing software integrates seamlessly with your existing systems, protecting your investments and eliminating silos. Rather than forcing you into a rip-and-replace model, we connect with what you already use, creating a smarter, more connected environment.

Supported integrations include:

- ERP software (SAP, Oracle, Microsoft Dynamics, Epicore and Infor): Connect financial and operational data for stronger alignment between production and business performance.

- MES systems: Coordinate execution and shop-floor control, ensuring schedules translate directly into actionable tasks.

- MRP tools: Synchronize material requirements with production schedules, reducing shortages and overstock.

- PLM systems: Link product design with manufacturing to streamline engineering change orders and reduce delays.

- QMS software: Ensure compliance, traceability, and quality management across regulated industries.

- CRM platforms: Align customer orders and requirements directly with scheduling and production capacity.

By creating a unified digital ecosystem, Synchrono® supports smart factory technology initiatives and enables end-to-end supply chain synchronization. This integration delivers:

- Scalable growth, as systems expand alongside your business without disruption.

- Interoperability across platforms, removing the inefficiencies of disconnected tools.

- Streamlined decision-making, with one connected source of truth accessible to every department.

With Synchrono®, you’re not just running isolated systems—you’re building a foundation for Industry 4.0 and future-ready operations. Our integrations reduce duplicate work, accelerate adoption, and enable enterprise-wide visibility. The result is maximized ROI from your current IT stack while preparing your organization for long-term digital transformation.

Real-Time Visibility from Shop Floor to Enterprise

In today’s manufacturing environment, factory floor visibility is not optional. Without it, companies risk late deliveries, missed commitments, and costly inefficiencies.

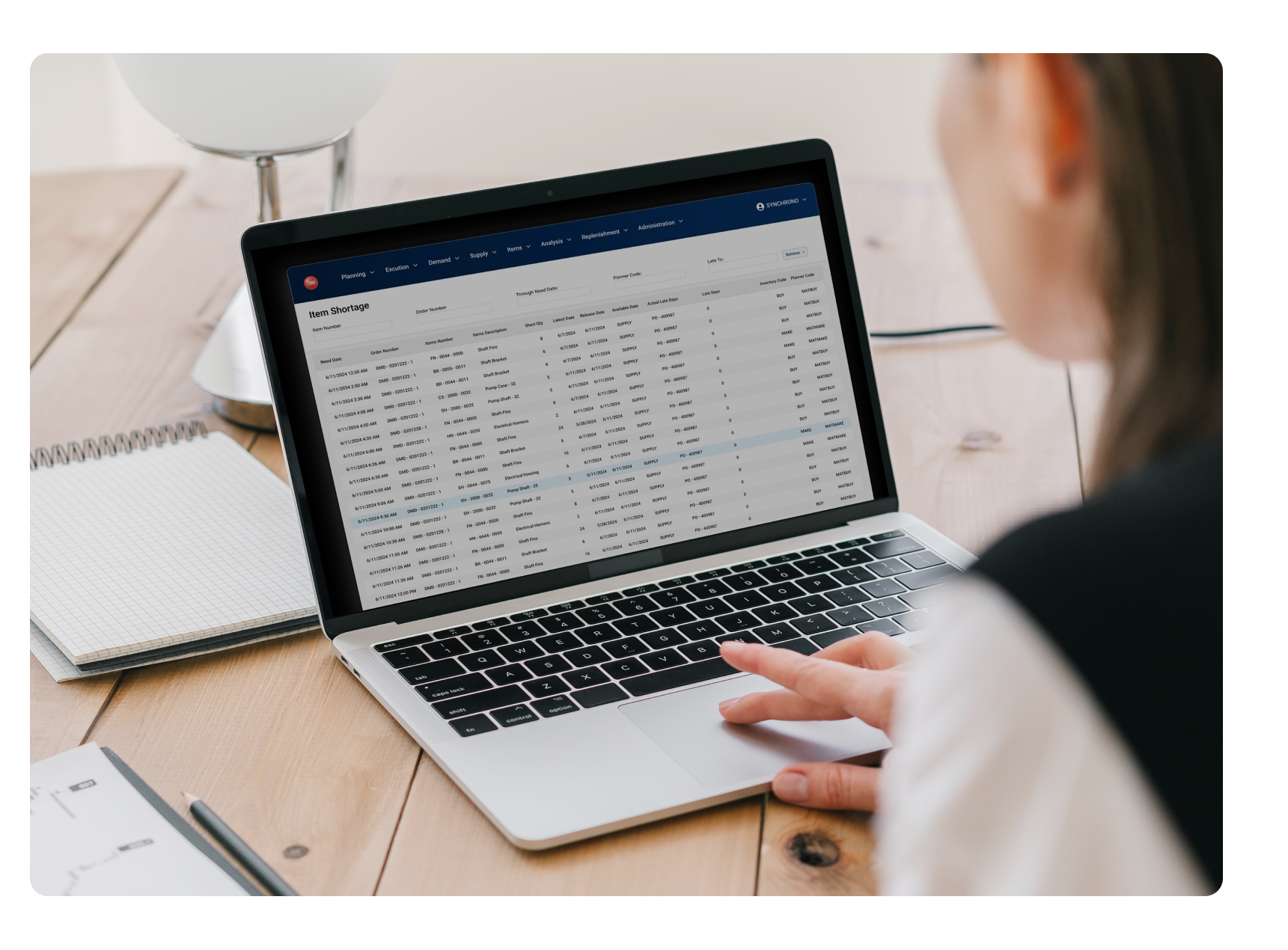

Synchrono® provides real-time manufacturing software that gives every stakeholder—from operators to executives—instant access to the data they need. From order release to final shipment, every update is tracked in real time. This eliminates guesswork, prevents misalignment, and ensures that priorities are clear at every level.

Use case example: When an order is released, Synchrono® automatically updates labor assignments, material availability, and machine schedules. Operators see their tasks instantly, managers gain insight into workflow progress, and executives monitor key performance metrics. This level of operational efficiency ensures your entire team works from one accurate version of reality.

Beyond shop-floor control, Synchrono® visibility tools strengthen collaboration between departments and across multi-site operations. Shared data enables consistent reporting, more accurate demand planning, and faster responses to disruption. Manufacturers that adopt this approach not only achieve greater efficiency but also gain a competitive edge through predictable, customer-focused delivery performance.

Transform Production with Data-Backed Decisions

True improvement comes from actionable data—not guesswork. Synchrono® aggregates, analyzes, and synchronizes information from across your enterprise, turning raw data into meaningful insights that fuel smarter decision-making. With advanced manufacturing analytics built into our platform, every team member has the visibility they need to act with confidence.

Our analytics tools provide insights into:

- Throughput trends: Identify where flow slows down and prioritize improvements to keep work moving efficiently.

- Cycle times and WIP levels: Highlight inefficiencies, bottlenecks, or rework areas that increase lead times.

- Capacity constraints: Pinpoint limits in labor or machines that prevent operations from meeting demand.

- Scheduling optimization opportunities: Reduce late orders, overtime, and costly expediting by aligning resources with demand.

The impact in real time: With live production updates, Synchrono® ensures plant managers, engineers, and executives always work from the same accurate data. For example, clients using SyncView®, a real-time dashboard software, report a 25% faster response to disruptions because issues are flagged early, preventing cascading delays and missed deliveries.

Why it matters: By combining analytics with production scheduling software, manufacturers gain the ability to adjust quickly, improve manufacturing flow, and achieve measurable ROI. These insights empower teams to:

- Lower operational costs by reducing waste and overtime.

- Boost throughput and order fulfillment without additional capital investment.

- Support continuous improvement programs with concrete performance data.

Ultimately, Synchrono® analytics help create a culture of improvement where decisions are backed by evidence, not assumptions—building long-term efficiency and competitive advantage in dynamic markets.

Why Manufacturers Choose Our Production Software

For more than two decades, Synchrono® has been helping manufacturers transform their operations with powerful manufacturing software for their production. We combine innovative technology, deep industry expertise, and proven improvement frameworks to deliver sustainable, measurable results that scale over time.

Key reasons manufacturers trust Synchrono®:

- 25+ years in manufacturing technology – We’ve supported companies of every size, from single-plant operations to global enterprises, delivering consistent results in throughput, cost savings, and delivery performance. Our long history provides not just software but also strategic guidance grounded in proven success.

- Trusted across industries – Our software powers operations in aerospace and defense, automotive, electronics, capital equipment, and more—each with unique complexities, regulations, and customer demands. By implementing our highly flexible tools in these environments, Synchrono® helps teams solve their most pressing production challenges while maintaining compliance.

- Supports continuous improvement – Designed to align with lean practices and the Theory of Constraints, our platform ensures that every investment you make also drives long-term efficiency and waste reduction. Synchrono® tools evolve with your processes, sustaining gains over years instead of months.

- Unified platform – By integrating scheduling software, analytics, replenishment, and alerts, Synchrono® eliminates silos and gives every department access to the same real-time insights. This creates alignment from the factory floor to the executive suite, ensuring strategic goals translate into daily actions.

- Scalable digital manufacturing solutions – Whether you’re modernizing a single site or deploying across multiple plants, our tools adapt to your needs, enabling growth without costly overhauls. With Synchrono®, you gain a roadmap to future-ready operations that expands at your pace.

Synchrono® isn’t just another vendor. We’re a manufacturing company’s partner in operational excellence, equipping teams with the visibility, control, and agility they need to thrive in today’s volatile markets. By combining advanced planning, production scheduling, and real-time insights, we help you not just compete—but lead. Manufacturers who adopt our solutions consistently report stronger customer relationships, faster time-to-value, and a foundation for continuous growth.

Real Results from Real Manufacturers

Synchrono® customers experience powerful, measurable outcomes that drive transformation. Using demand-driven manufacturing principles, organizations achieve results that go far beyond incremental improvement.

These case studies highlight how Synchrono® solutions deliver lasting ROI, scalable performance gains, and competitive advantage across industries—proving that true operational excellence is both achievable and sustainable. Here are real-world examples spanning multiple industries:

Orbital ATK – Aerospace & Defense

At the Aerospace Structures Division (ASD) of Orbital ATK, a lean initiative using SyncKanban delivered significant operational gains:

- 30% reduction in WIP inventory

- 90% reduction in scrap

- Consolidation of 16 replenishment processes into a single system

- Increased production rates from Airbus A350 ramp-up from 1× to 4×, with plans for 12×

These improvements not only reduced waste but also created a repeatable model for scaling production. By aligning replenishment with real customer demand, Orbital ATK achieved a level of agility that traditional scheduling systems could not provide.

Dynisco – Plastics Extrusion

Dynisco achieved remarkable improvements with real-time, demand-driven synchronization:

- 40% reduction in replenishment inventory

- 91% improvement in inventory turns

- Lead times dropped from 12 to 2 weeks, unlocking millions in new revenue

This transformation shows the impact of pairing advanced scheduling software with lean manufacturing practices. The ability to cut lead times so drastically allowed Dynisco to meet customer orders faster, improve competitiveness, and reinvest savings into growth initiatives.

GIW Industries – Heavy Equipment

GIW doubled its revenue within 2½ years after implementing SyncManufacturing. Key transformation metrics include:

- Sharper delivery predictability and shorter cycle times

- Added operating capacity that enabled entry into new markets, such as oil sands

For GIW, Synchrono® software provided more than just incremental improvements; it fundamentally shifted how the company approached capacity and throughput. By creating visibility into constraints and aligning schedules with real-world conditions, GIW turned operational efficiency into a strategic advantage.

Get Started with the Synchrono Platform

Synchrono® makes it simple for manufacturers to take the next step toward synchronization. Whether you’re exploring production scheduling tools, evaluating operational efficiency software, or seeking scalable digital manufacturing solutions, our consultative team will guide you every step of the way.

From onboarding to long-term support, we ensure a smooth adoption process. With seamless integration with your ERP software and existing factory systems, empowering your teams with minimal disruption.

Manufacturers who partner with Synchrono® gain confidence that their investment in manufacturing production software will deliver measurable returns. With capabilities ranging from real-time manufacturing software to supply chain synchronization, you’ll have the flexibility to solve today’s challenges while preparing for tomorrow’s growth.

The best way to see the potential is through a live demo. You’ll experience firsthand how Synchrono® connects planning, execution, and analytics to create a synchronized operation built for scalability, agility, and profitability.