Advanced Planning and Scheduling Software

SyncManufacturing® is advanced planning and scheduling (APS) software powered by demand-driven, constraint-based algorithms. As a leading manufacturing scheduling software solution, it synchronizes and prioritizes the entire order-to-delivery process in real time. This helps discrete manufacturers reduce lead times, improve production efficiency, and ensure on-time deliveries while increasing throughput.

Transform Schedule Builders into Schedule Analyzers

Equip planners and schedulers with software designed to prioritize what truly matters at the right time. SyncManufacturing® takes on the heavy lifting, giving your team a smarter, more effective way to work.

Stop Rebuilding Schedules

Instead of manually rebuilding schedules, teams can focus on analyzing and optimizing them. SyncManufacturing eliminates repetitive tasks, freeing up valuable hours.

Leverage Advanced Algorithms

Advanced algorithms automatically optimize workflows, ensuring operations run smoothly even when disruptions occur.

Data-Driven Decision-Making

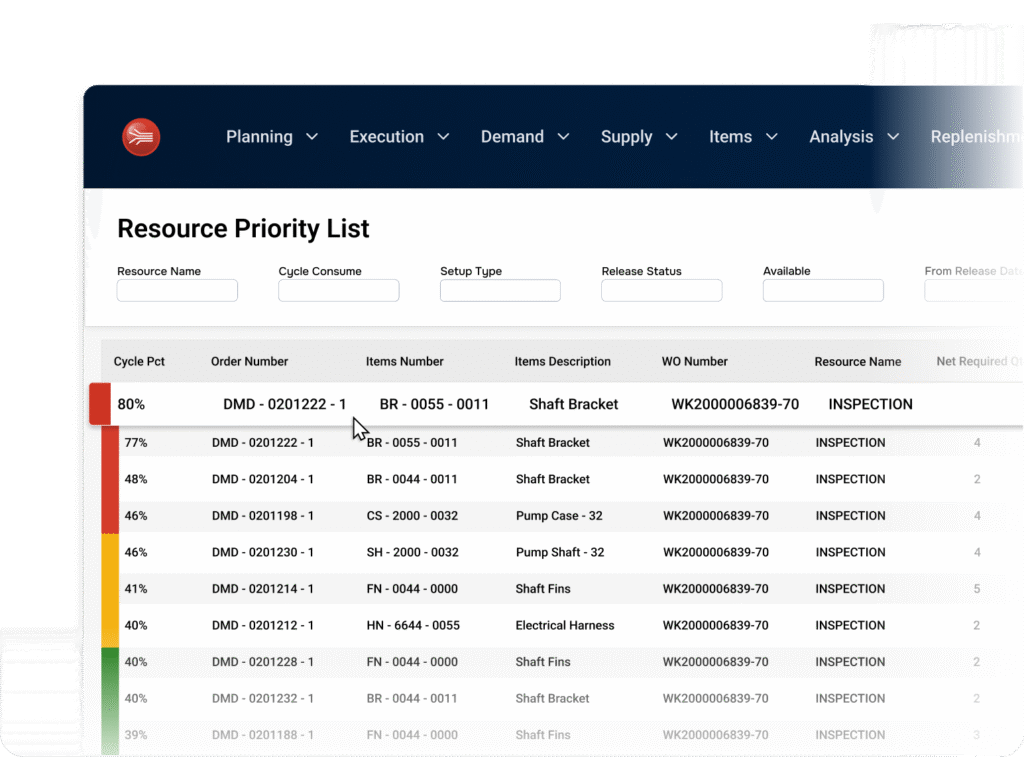

With access to comprehensive, real-time data, planners can visualize bottlenecks, evaluate constraints, and plan ahead with confidence—transforming their role from reactive schedulers into proactive decision-makers.

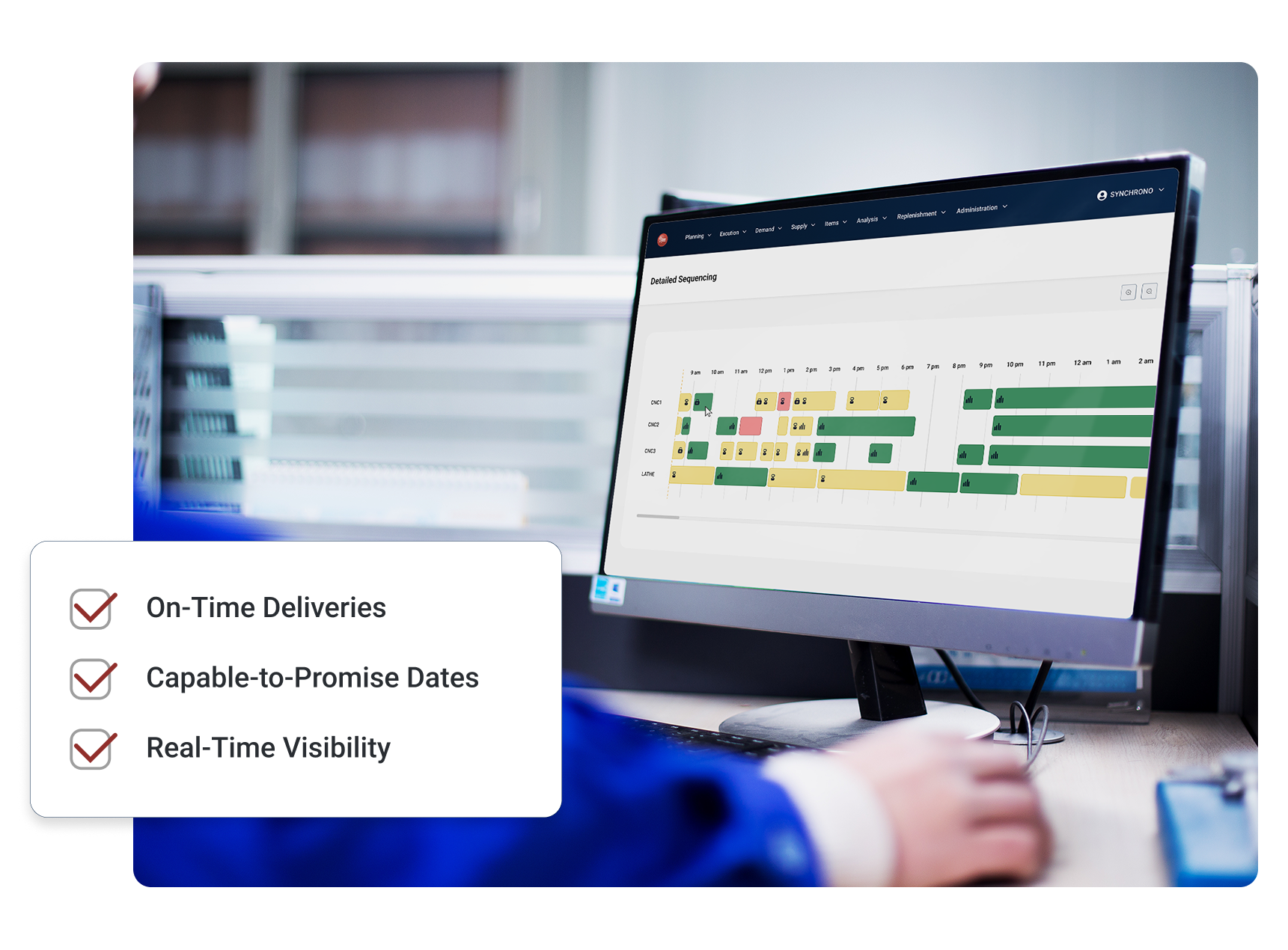

Reliable Planning with Finite Capacity Scheduling

SyncManufacturing® delivers finite capacity planning that ensures every resource—labor, machines, and materials—is scheduled within actual availability. By preventing overloads and accounting for constraints, manufacturers can provide accurate capable-to-promise scheduling dates with confidence.

This accuracy builds trust with customers and eliminates the costly cycle of expediting or rescheduling.

Stay Ahead and Stay Aligned

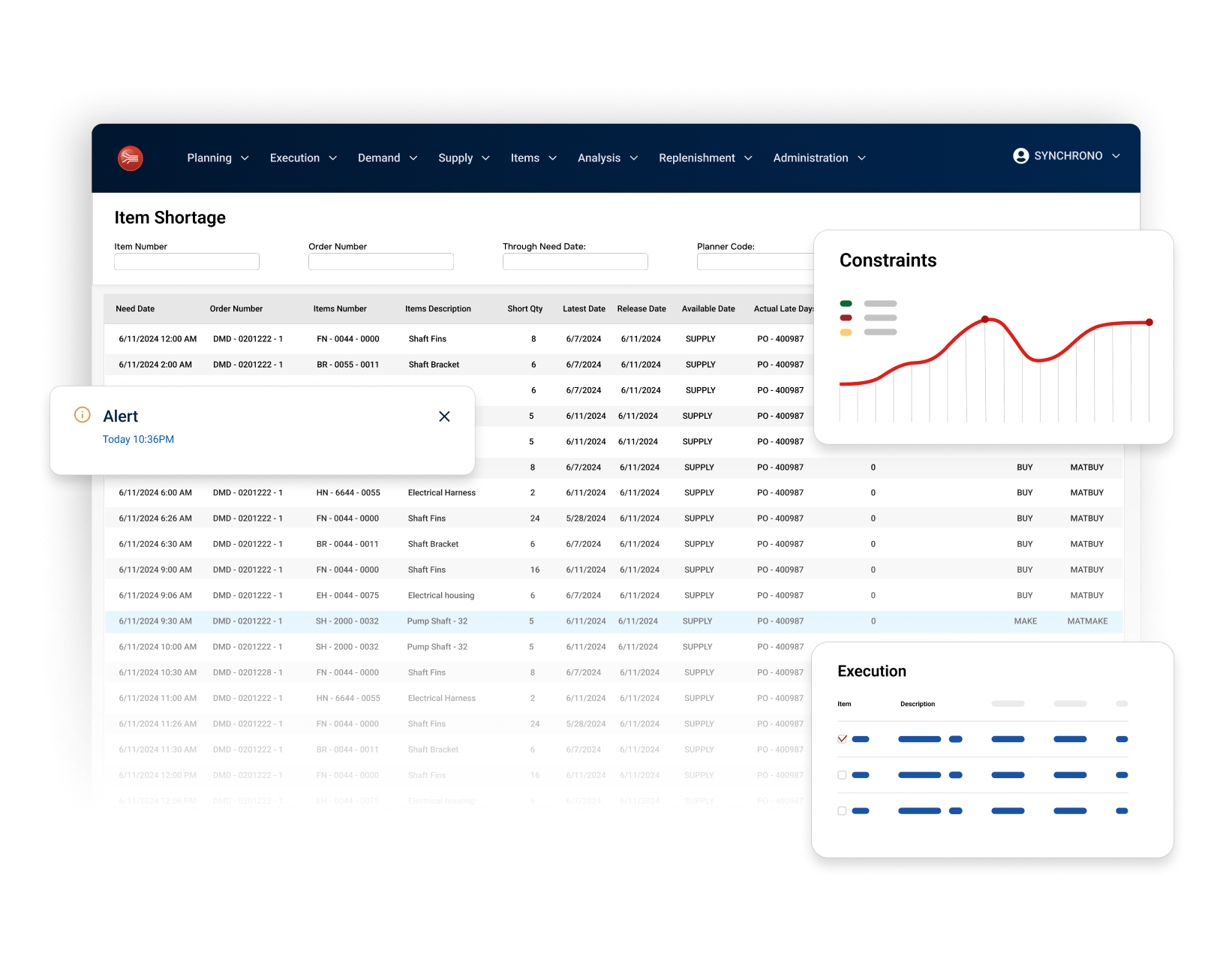

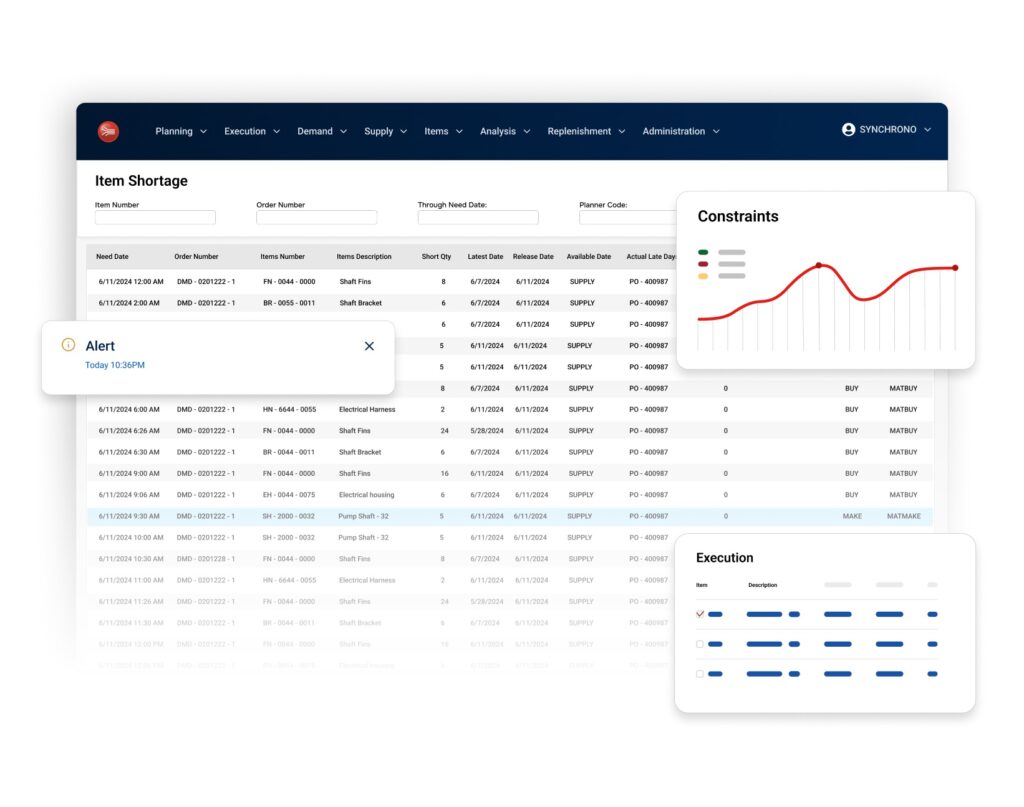

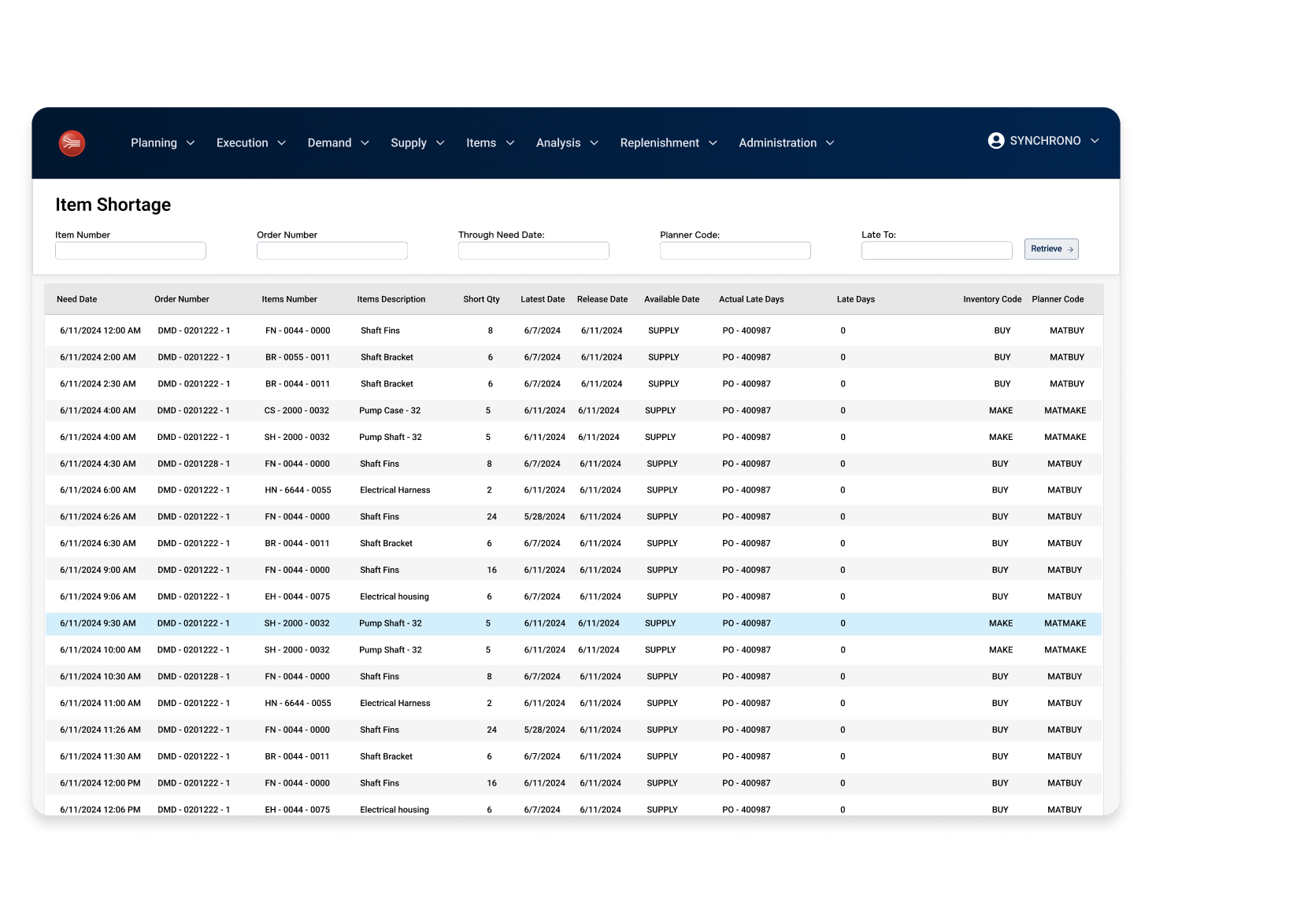

In today’s fast-moving markets, waiting for end-of-day reports isn’t enough. SyncManufacturing® gives every stakeholder real-time visibility into the production process, empowering faster, smarter decisions.

For example, one manufacturer prevented a major delivery delay when early alerts revealed a shortage in critical materials. This proactive insight exemplifies how demand-driven manufacturing keeps operations resilient, predictable, and responsive to customer needs.

Proven Results with SyncManufacturing Scheduling Software

For more than 25 years, Synchrono® has delivered measurable impact through its scheduling system for manufacturers. Customers consistently achieve dramatic improvements in speed, reliability, and revenue growth, including:

From 3-4 Weeks to Under 5 Days

Reduced Lead Times

Doubled Revenue

In 2.5 Years

From 50% to 98%

Improved On-Time Shipments

Why Choose SyncManufacturing?

- Demand-Driven: Improve synchronization, visibility, and throughput based on real-time demand signals. (e.g., reduced lead times across complex job shops).

- Built for Complexity: Handles constraints and excels in the most challenging discrete manufacturing environments. (e.g., improved throughput across multi-plant networks).

- Lean Manufacturing Principles: A true lean manufacturing software foundation that drives waste elimination and productivity gains. (e.g., reduced excess WIP and inventory).

- Expert Guidance: Synchrono® consultants tailor solutions to each client, ensuring smoother onboarding and faster ROI. (e.g., achieved CTP date reliability within 90 days).

Integrations and Compatibility

SyncManufacturing® integrates with your existing systems through standard APIs, reducing risk and eliminating data silos. With event-based integrations with the tools you already use, it ensures that production decisions are based on current, actionable information, creating ripple effects throughout your organization.

Key integrations include:

- ERP Software: SAP, Oracle, Microsoft Dynamics, others

- MES Systems: Aligns with shop floor execution tools

- Synchrono Suite: Works seamlessly with SyncAlert®, SyncView®, and SyncKanban®

Industry Applications

- Defense: Align high-compliance schedules with strict delivery deadlines.

- Aerospace: Manage complex, multi-step assemblies with full visibility.

- Capital Equipment: Adapt to custom builds and project-based workflows.

- Industrial Machinery: Support mixed-mode scheduling for make-to-order and make-to-stock.

See the ROI of SyncManufacturing Scheduling Software

SyncManufacturing® is more than just a manufacturing scheduling tool—it’s a scalable scheduling system for manufacturers that drives measurable returns. Discover how automation, integration, and continuous improvement can unlock new levels of production efficiency in your business.

What is Advanced Planning and Scheduling?

Advanced Planning and Scheduling (APS) is a method and toolset for building realistic, constraint–aware production plans that align actual capacity with customer demand. SyncManufacturing APS software goes beyond basic MRP or spreadsheet scheduling by considering finite capacity constraints, materials availability, and real time shop floor conditions so manufacturers can commit to reliable due dates, reduce lead times, and improve flow.

How does SyncManufacturing® APS software work?

SyncManufacturing APS software pulls data from your existing systems, such as ERP, MES, and shopfloor data sources, and applies scheduling logic that reflects real-world limits on factory capacity and material availability to generate an optimized production schedule that maximizes manufacturing throughput and on-time delivery while minimizing WIP.

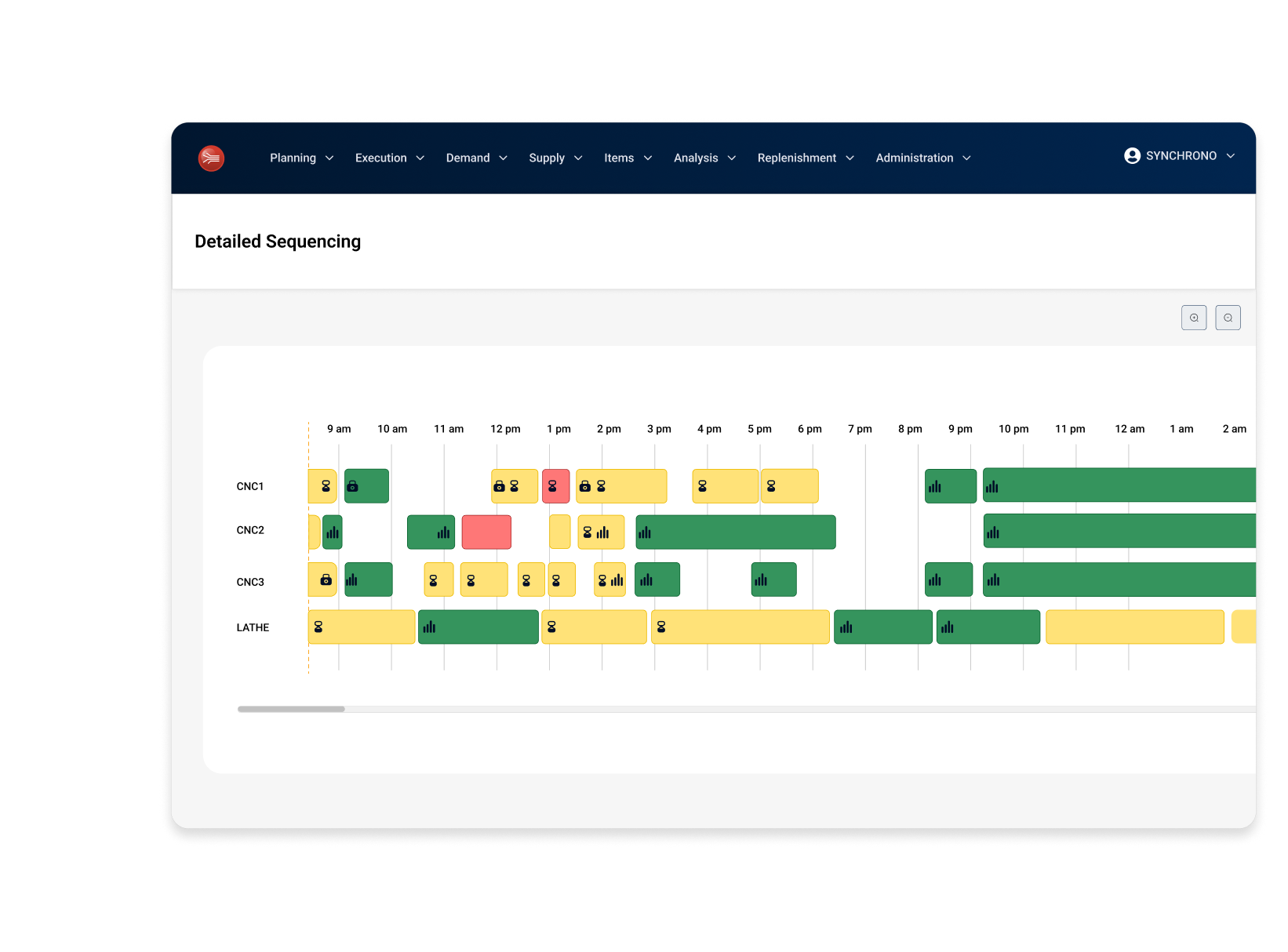

SyncManufacturing also uses real-time shop floor feedback to adjust schedules as conditions change, so planners and supervisors always work from a current, feasible plan instead of static snapshots. Drag and drop functionality gives planners and schedulers an easy way to fine tune schedules and immediately see how each change impacts the production schedule.

Becoming more customer-focused is a strategic objective for our organization. Can APS software help us do that?

SyncManufacturing APS software helps manufacturing organizations become more customer-centric by aligning production plans with real customer demand, improving delivery reliability, and enabling faster, more accurate responses to changing customer needs. Here are four specific examples of how our customers are using SyncManufacturing to strengthen customer relationships and build trust.

Improve on-time delivery rates: SyncManufacturing uses finite capacity scheduling so promised ship dates are based on real resource availability, not rough estimates, which improves on-time delivery and due date performance. Consistently meeting promised delivery dates strengthens customer trust and also reduces the need for expensive expediting or last-minute rescheduling that can disrupt other customer orders.

Respond faster to demand changes: Real-time production updates to quickly adjust plans when customers change order quantities, request rush jobs, or alter priorities while still protecting overall schedule performance and minimizing the impact on other customer orders.

Support reliability and continuous improvement: SyncManufacturing APS highlights manufacturing bottlenecks and production constraints, helping teams address the root causes of late orders and long lead times that impact on-time delivery rates. Over time, consistently addressing bottlenecks and managing constraints translates into shorter lead times, higher service levels, and a reputation for dependable delivery.

Increase visibility for customer service: SyncManufacturing gives sales, customer service, and planners instant, detailed visibility into order status, constraints, and capacity, enabling proactive communication with customers. Customer-facing teams can answer “when will I get my order?” without having to bother operations, reducing the time it takes to provide a reliable answer and lessening the burden on production managers.

Can SyncManufacturing® APS help us implement Lean manufacturing principles?

SyncManufacturing APS is built on Lean manufacturing principles and demand driven concepts and is designed to help manufacturers reduce waste and improve flow. Here are some examples:

SyncManufacturing uses pull based, demand driven planning to release work only as needed, which helps limit WIP, shorten lead times, and avoid overproduction. Synchronizing materials, machines, people, and information around actual customer demand reinforces core Lean manufacturing goals of improving flow and responsiveness.

SyncManufacturing improves flow by managing constraints and making bottlenecks and material shortages visible so operations managers can uncover the root causes and ensure work flows smoothly through the value stream. This supports Lean efforts to eliminate waiting, excess inventory, and unnecessary motion or rework. Realtime, finite-capacity scheduling also reduces expediting, which cuts wasteful overtime and helps stabilize processes.

SyncManufacturing makes it easy to adjust the model to reflect gains from kaizen and value stream improvements. Visibility into performance, constraints, and WIP levels also gives teams the data needed to prioritize Lean continuous improvement projects and sustain these improvements over time.

Learn how SyncView can improve visibility across the enterprise.

How can SyncManufacturing® help us improve manufacturing KPIs like on-time deliveries and lead time?

SyncManufacturing APS software helps improve on– time delivery and reduce lead time by creating realistic, constraint-based schedules that synchronize production with actual customer demand. Instead of pushing work into the plant based on infinite capacity assumptions, SyncManufacturing acknowledges finite resources and material availability so due dates are achievable and work is released and prioritized appropriately. This reduces chaos, expediting, and rework—all common causes of late orders and long, unpredictable lead times.

Using patented CONLOAD™ gating and demand-driven logic, SyncManufacturing limits WIP and keeps queues under control at critical constraints, shortening cycle times and smoothing factory flow. Planners can see the impact of changes on delivery promises, capacity, and constraints in real time, then adjust sequences or priorities with intuitive tools rather than relying on spreadsheets or manual reshuffling.

Does SyncManufacturing® work with my current ERP software, or will I need to replace it?

SyncManufacturing APS software is designed to integrate with your existing ERP system to enhance its planning and scheduling capabilities rather than duplicate or replace them. Your ERP system remains the system of record for orders, inventory, and master data.

Using standard APIs, our team has effectively implemented SyncManufacturing alongside SAP, Microsoft D365, Infor, Epicor, Oracle, and many other ERP systems. This approach protects your existing ERP investment, eliminates duplicate data entry, and lets ERP continue doing what it does best while APS handles constraint-based, finite-capacity scheduling and real-time synchronization.

How “clean” does my ERP data need to be before implementing SyncManufacturing®?

Many ERP systems lack the agility needed to keep up with real-world production environments. In fact, we rarely walk into a manufacturing environment where the customer is happy with their data accuracy at the start of the implementation. During a SyncManufacturing implementation, our team will help you focus on the data that matters most to determine the most effective implementation path.

What types of manufacturing environments are best suited for SyncManufacturing®?

SyncManufacturing is best suited for complex discrete manufacturing environments where variability, high mix, and multistep routings make traditional ERP or spreadsheet scheduling unreliable. Examples include aerospace and defense, automotive supply, capital equipment, electronics, heavy equipment, medical devices, and other discrete industries that manage complex bills of material, frequent changeovers, and tight customer commitments. In these environments, SyncManufacturing constraint-based, finite capacity scheduling and real-time synchronization help manage complexity, prevent resource overloads, and keep flow aligned with actual demand.

Can SyncManufacturing® support advanced planning and scheduling across multiple locations?

Yes, SyncManufacturing can help synchronize planning and scheduling across multiple facilities so everyone works from one accurate version of reality.This allows planners to coordinate load, priorities, and promise dates across plants instead of scheduling each site in isolation, balancing demand with enterprise capacity, reducing cross site firefighting, and maintaining more reliable lead times and on–time delivery across the network.

How quickly can we start seeing the benefits of implementing SyncManufacturing®?

While every implementation is unique, many sites can go live in as little as 120 days once the project is scoped and resourced. This timeframe includes configuration, integration with existing systems, testing, and user training. Multisite rollouts are often staggered, but in organizations where processes are standardized across the enterprise, additional sites can typically be brought online even faster. Having a clear project team, defined objectives, and executive sponsorship helps manufacturers realize advanced planning and scheduling benefits sooner.

View our case studies to learn more about real-world SyncManufacturing implementation experiences.