Manufacturing Software Solutions for Discrete Operations

Synchrono® delivers purpose-built software that empowers discrete manufacturers to increase visibility, streamline flow, and drive measurable results.

Software Built for Discrete Manufacturing

Most manufacturing software is designed for broad use cases. Synchrono® focuses on discrete manufacturing systems, giving teams tools tailored to complex assemblies, unique orders, and multi-step production.

With Synchrono®, you can:

- Manage complex bills of materials and routings.

- Support lean manufacturing practices with built-in pull-based scheduling and execution functionality.

- Achieve synchronization in complex and highly variable processes.

- Simplify scheduling of high mix environments through sophisticated, automated scheduling algorithms.

Unlike generic ERP software, our solutions handle real-world complexity with ease, ensuring teams have the speed and adaptability to meet demand.

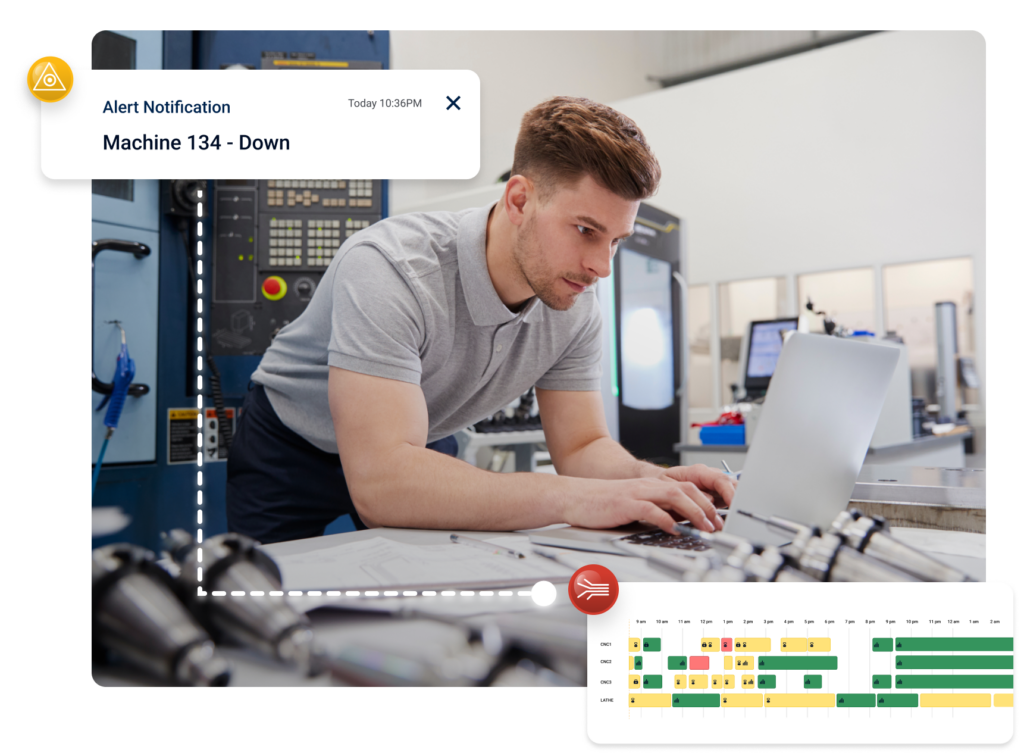

Real-Time Planning and Scheduling

Spreadsheets, homegrown apps, and basic manufacturing ERP software often fail when production gets complex. They can’t adapt quickly or manage variability.

SyncManufacturing®, our advanced planning and scheduling software, provides:

- Finite capacity scheduling that prevents overloading.

- Constraint-based scheduling to manage critical resources.

- Real-time production scheduling that adapts instantly to shop floor changes.

- Automated scheduling tools that eliminate manual work.

With SyncManufacturing®, operations teams shift from building schedules to analyzing performance and driving efficiency.

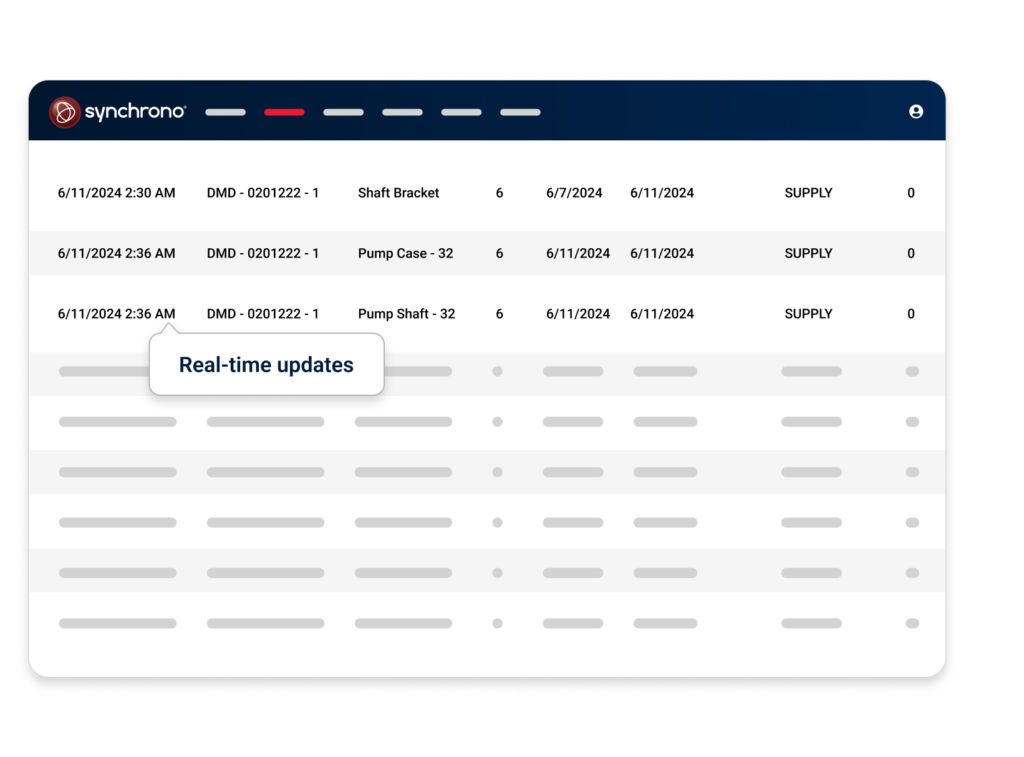

Flow and Inventory Control with eKanban

Traditional Kanban systems can’t keep pace with lean or just-in-time requirements. SyncKanban® modernizes replenishment by supporting pull-based manufacturing and demand-driven production.

SyncKanban® provides:

- Automated eKanban signals with no manual card errors.

- Reduced inventory waste through real-time replenishment.

- Full support for pull-based, demand-driven operations.

From single plants to multi-site enterprises, SyncKanban® ensures stable flow and smarter inventory control.

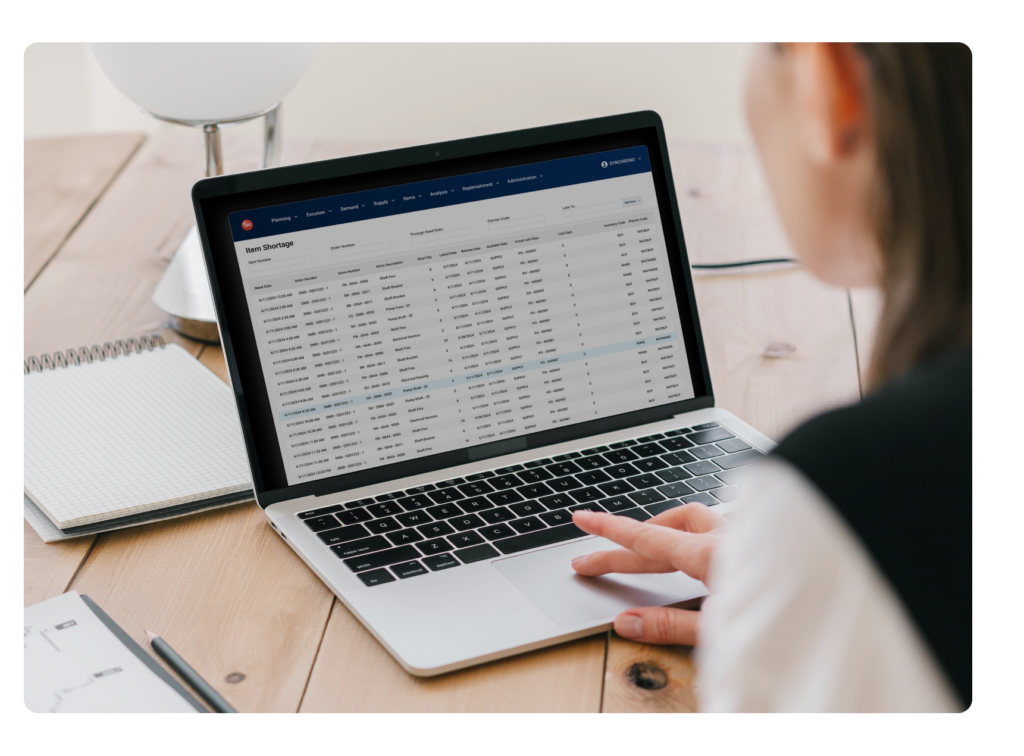

Analytics, Constraints, and Continuous Improvement

Synchrono® analytics give leaders insights that tie directly to production scheduling. Data connects to real scheduling and flow decisions, supporting continuous improvement.

Our tools help identify:

- Constraints slowing production.

- Throughput trends affecting performance.

- Inventory and cycle-time patterns that reveal lean opportunities.

Grounded in Lean and Theory of Constraints, Synchrono® equips manufacturers with confidence to refine processes and build long-term resilience.

Start Solving Production Problems Today

Synchrono® offers a full suite of manufacturing software solutions: SyncManufacturing®, SyncView®, SyncAlert®, and SyncKanban®. Start with one tool and effortlessly scale as you grow–data remains connected and systems work together to optimize your entire enterprise for maximum efficiency and control.

With Synchrono®, manufacturers gain:

- Greater visibility into orders and flow.

- Measurable improvements in throughput and delivery.

- The ability to move from reactive management to proactive control.

Now is the time to take action. Book a demo to see how Synchrono® can transform your operations.