Automated Production Scheduling for Modern Manufacturing

Modern discrete manufacturers face constant pressure to deliver faster, reduce costs, and remain competitive in a global market. Manual spreadsheets and outdated scheduling practices can’t keep up with today’s demands. Automated production scheduling replaces guesswork with data-driven precision, providing faster decision-making, fewer delays, and optimized throughput. For organizations seeking real-time production scheduling that supports Lean and demand-driven manufacturing, advanced planning and scheduling software offers a proven path forward.

Why Manual Scheduling No Longer Works

Traditional scheduling methods often rely on spreadsheets, whiteboards, or manual updates. While these tools may work for simple operations, they quickly fall apart in complex, high-mix environments. Manual scheduling is slow, error-prone, and reactive, leaving manufacturers vulnerable to disruptions.

Without automation, scheduling errors multiply. Missed deadlines frustrate customers, poor resource allocation drives up costs, and managers struggle to balance priorities across machines, shifts, and orders. Spreadsheets simply cannot provide the visibility needed to handle unexpected changes, such as urgent orders or machine downtime.

By contrast, an automated scheduling system powered by advanced planning and scheduling software adapts instantly to real-world conditions. Whether it’s a sudden order change or an equipment failure, schedules are recalculated in seconds, ensuring alignment with finite capacity planning principles. This approach supports both Lean manufacturing and Theory of Constraints methodologies, helping manufacturers focus on pull-based methodologies and constraint management to maximize throughput.

Risks of Manual Scheduling

Errors & Oversights

Human error in spreadsheets leads to incomplete or outdated schedules, creating cascading problems across the shop floor. These mistakes often go unnoticed until they disrupt production flow, forcing last-minute fixes that waste valuable time and resources.

Missed Deadlines

Inflexible systems cannot adapt to shifting priorities, resulting in late deliveries and disappointed customers. As order changes pile up, the lag in schedule updates makes it nearly impossible to recover lost time, damaging customer trust and repeat business.

Poor Resource Allocation

Without accurate data, managers overcommit or underutilize labor, machines, and materials. This imbalance inflates operational costs and reduces efficiency, making it harder to achieve throughput goals or scale operations profitably.

Local Optimization

Traditional scheduling methods often focus on optimizing a single resource or work center without considering how those changes affect the entire production flow. This siloed approach creates bottlenecks and idle time elsewhere in the process, reducing overall throughput and system-wide efficiency.

The Advantages of Automated Scheduling

Adopting production planning software gives manufacturers a competitive edge by aligning schedules with real-world capacity and constraints. The production scheduling software benefits extend far beyond efficiency. They directly impact customer satisfaction, profitability, and scalability.

Key outcomes of automated scheduling include:

- Increase Throughput – Automated scheduling systems optimize resource utilization with a focus on optimized flow and throughput of the entire value stream(s). This means higher productivity without adding new equipment or personnel. Manufacturers can scale production while maintaining efficiency.

- Meet Due Dates – By aligning schedules with finite capacity planning, manufacturers dramatically improve on-time performance. Instead of relying on guesswork, schedules reflect actual constraints, giving customers confidence that promises will be met.

- Reduce Waste – Automated scheduling not only greatly reduces the amount of time manually building schedules, but also minimizes idle time, overproduction, and costly rework in the production process. This aligns with Lean manufacturing scheduling practices by eliminating non-value-added activities. Waste reduction also frees resources for innovation and continuous improvement.

- Adapt in Real Time – When constraints shift, such as a priority order or unplanned downtime, the system automatically recalculates. This ensures schedules remain accurate and production flow continues without disruption.

By leveraging advanced planning and scheduling software, companies gain the agility to meet evolving market demands while building a foundation for sustainable growth.

How It Works: Inside the Synchrono® Approach

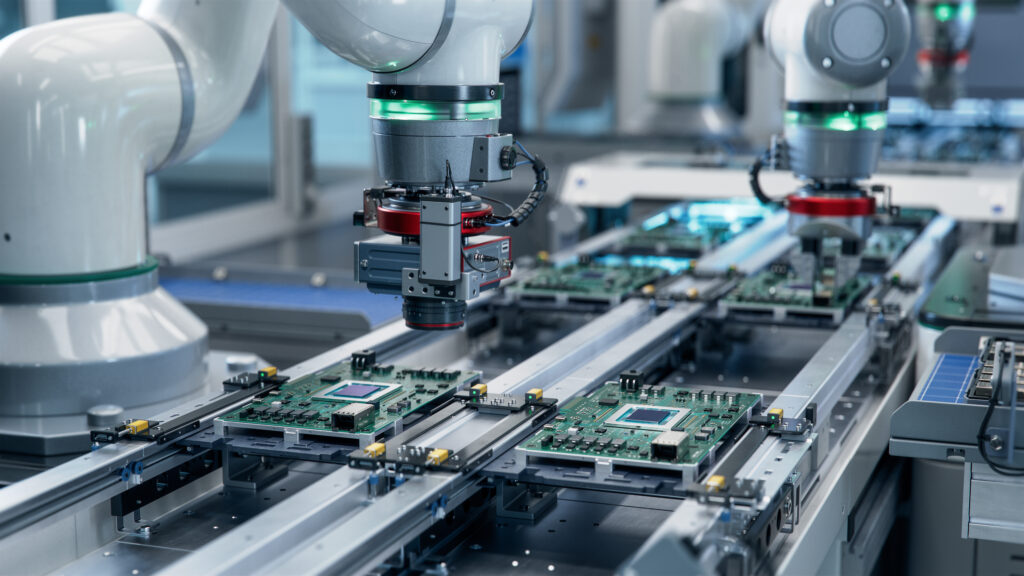

Unlike ERP or spreadsheets, Synchrono® APS software is purpose-built for discrete manufacturing scheduling. It goes beyond static planning to deliver real-time production scheduling that integrates with all layers of the manufacturing ecosystem.

At its core, Synchrono® software uses advanced algorithms to optimize schedules based on finite capacity planning and constraint management. Instead of overloading resources, the system calculates realistic workloads, ensuring commitments are achievable.

This approach integrates seamlessly with ERP, MES, and other systems to unify production planning and scheduling. By combining demand-driven manufacturing logic with pull-based scheduling, manufacturers can prioritize high-value orders while keeping flow responsive to real-world conditions.

The result: a proactive, synchronized system that maximizes efficiency while aligning with customer expectations.

Scheduling for Discrete Manufacturing Industries

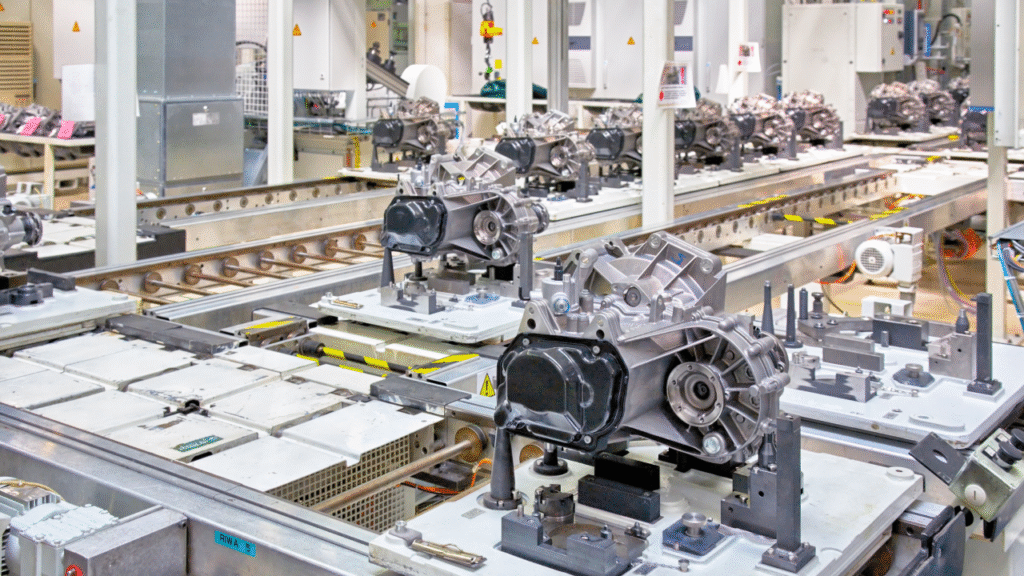

Automated production scheduling delivers value across industries, but discrete manufacturers with complex requirements often gain the most. These environments demand precision, agility, and coordination across extended supply chains.

- Aerospace & Defense – Manage long lead times and strict delivery requirements while ensuring compliance with regulatory standards. Automated scheduling provides the flexibility to adapt to engineering changes without sacrificing commitments.

- Capital Equipment – Handle engineer-to-order workflows and complex bills of materials with confidence. Real-time production scheduling ensures resources are allocated efficiently across multiple projects.

- Industrial Machinery – Improve delivery reliability for high-volume, high-mixorders. Automated scheduling reduces idle capacity and ensures production lines remain balanced.

- Automotive Suppliers – Balance just-in-time inventory requirements with multi-tiered supply chain demands. Integration with supply chain management systems ensures smooth collaboration with OEM partners.

For these industries, automated scheduling is not just a tool. It is a necessity for staying competitive in global markets.

Standout Features of SyncManufacturing®

Synchrono® offers a unique combination of features that extend beyond traditional manufacturing software solutions. Rather than treating scheduling as a standalone task, its approach integrates capacity, constraints, alerts, and visibility into one cohesive system. Each capability is designed to enhance flow, improve visibility, and strengthen collaboration, giving manufacturers the tools they need to meet today’s complex production challenges.

Finite Capacity Planning

Prevents overloading resources by aligning schedules with actual production capacity. This ensures commitments are realistic and delivery dates are met. By considering every constraint, machines, labor, and materials, finite capacity planning eliminates the unrealistic assumptions that often cause MRP software delays.

End-to-End Planning (via Supply Allocations)

SyncManufacturing® uses proprietary supply allocation logic to automatically link work orders across every level of the bill of material, from components and sub-assemblies to the finished product, creating one synchronized product flow. This end-to-end planning approach connects each work order to the final customer order, allowing manufacturers to plan and manage the entire build as an interconnected entity. By viewing the product structure as a whole, users gain advanced insight into critical paths, potential shortages, and the causes of delays, enabling faster, more informed decision-making.

Constraint Management

Identifies constraints and ensures resources are optimized around them, improving flow and throughput across operations. Instead of treating constraints as obstacles, Synchrono® turns them into focal points for improvement.

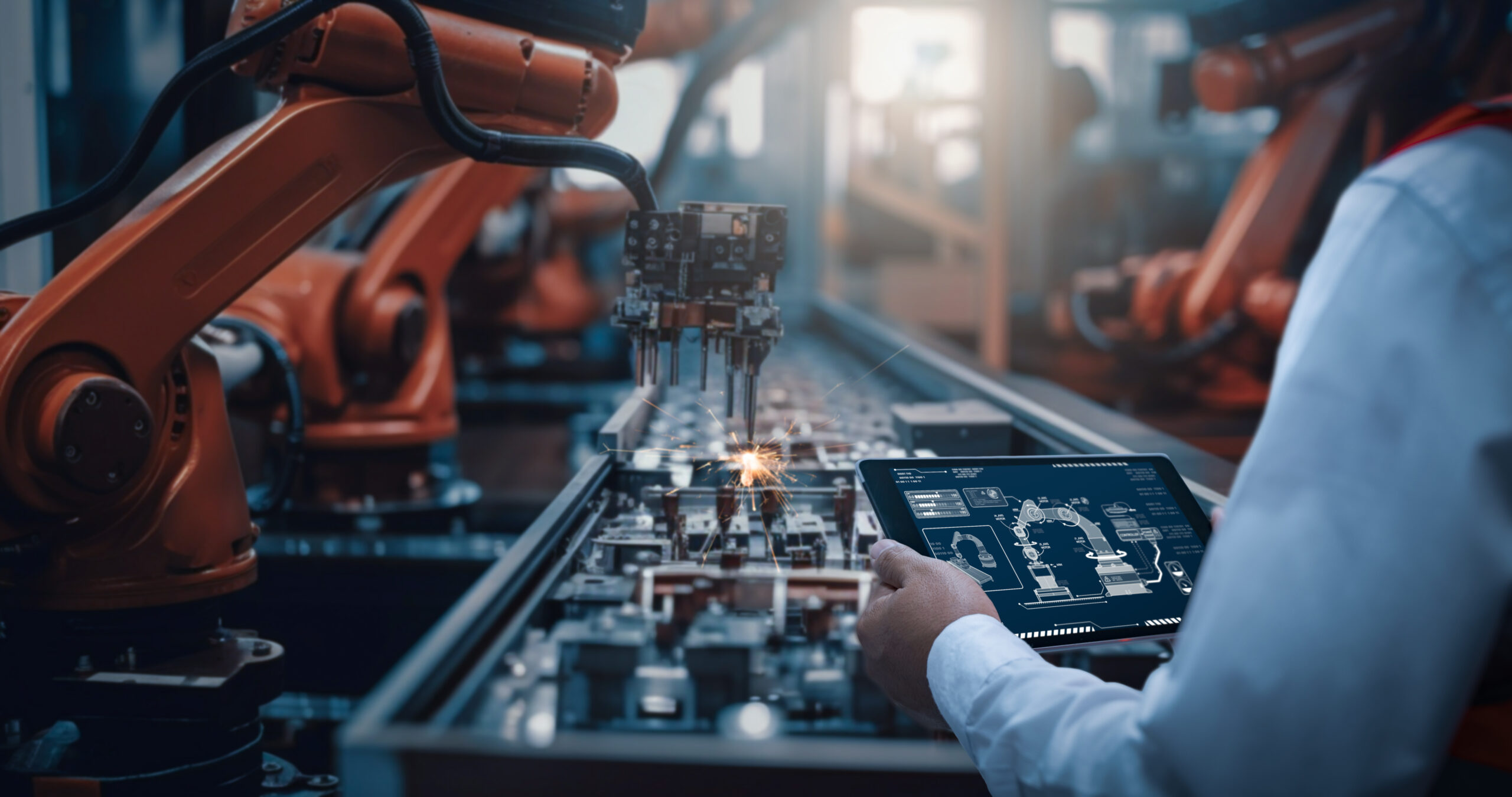

Adaptive Planning and Scheduling

Rather than relying on offline, batch scheduling, SyncManufacturing® enables real-time, incremental adjustments as conditions change. This keeps the schedule aligned with current data and priorities, ensuring the shop floor stays synchronized, responsive, and focused on maintaining flow.

Real-Time Alerts

Immediate notifications and automated escalation ensure that disruptions, such as machine downtime or supply delays, are addressed quickly. This reduces the risk of production delays. Powered by SyncAlert®, real-time alerts escalate issues to the right people instantly, preventing small disruptions from growing into serious problems.

Visualization

Provides full production transparency through dashboards and visual tools. Managers, operators, and executives can all access the same real-time information, improving alignment across the organization. Delivered through SyncView®, visualizations transform complex scheduling data into clear, actionable insights, enabling everyone to see priorities, progress, and risks at a glance.

Why Manufacturers Choose Synchrono®

For more than 25 years, Synchrono® has specialized in automated production scheduling for discrete manufacturing. Unlike general-purpose systems, its advanced planning and scheduling software is designed to handle the unique challenges of high-stakes industries such as aerospace, defense, capital equipment, and industrial machinery.

Proven Expertise

With decades of focus on manufacturing scheduling, Synchrono® has delivered measurable results for clients worldwide. Companies achieve better throughput, higher on-time performance, and reduced costs.

Demand-Driven, Pull-Based Scheduling

Synchrono® solutions are built on demand-driven manufacturing principles, aligning schedules with actual customer orders through pull-based scheduling methods.

Integrated Ecosystem

The Synchrono platform operates within a connected manufacturing ecosystem, aligning planning, scheduling, and execution through continuous integration with ERP, MES, and other manufacturing systems.

Built by Manufacturers for Manufacturers

Synchrono has been shaped by decades of hands-on manufacturing experience. Our team has a practitioner-first mindset that allows us to cut through the assumptions, expose hidden constraints, and design solutions grounded in reality.

Get Started Today

Automated production scheduling delivers measurable ROI by improving throughput, meeting due dates, and reducing waste. For manufacturers navigating increasing complexity, the right production planning software provides both immediate efficiency gains and long-term resilience.

Synchrono® offers an automated scheduling system that integrates seamlessly with your existing ecosystem, supports continuous improvement, and helps prevent the costly consequences of manual scheduling. By adopting a demand-driven approach powered by real-time production scheduling, you can reduce risk, strengthen customer relationships, and scale with confidence.