Escalation Management Software for Discrete Manufacturing

Manufacturers operate in complex, high-stakes environments where delays and unresolved issues can ripple across production lines, suppliers, and customers. Escalation management software is designed to bring order, speed, and visibility to these challenges—helping companies prevent delays and respond with confidence. By connecting alerts, workflows, and communication into one system, manufacturers gain the responsiveness needed to keep schedules on track.

Unlike manual methods, escalation tools provide a consistent, rules-based approach to handling disruptions. This ensures accountability across teams, reduces time wasted searching for root causes, and gives leadership clear visibility into what matters most. In fast-moving environments, that difference translates into fewer delays, greater reliability, and stronger performance.

The Cost of Unresolved Production Issues

In discrete manufacturing, even small problems can escalate into costly disruptions when left unaddressed. Delayed orders and missed deadlines lead to frustrated customers and strained supply chain relationships. Meanwhile, inefficiencies accumulate, idle labor, underutilized equipment, and expensive workarounds, all of which drive up costs.

Without a structured escalation management process, organizations often rely on reactive firefighting. By the time an issue is identified, production schedules may already be compromised, leading to longer lead times and unreliable delivery performance.

Key risks of unresolved issues include::

- Missed Commitments – Late shipments erode trust with customers and partners, often resulting in lost contracts.

- Increased Costs – Overtime, expedited freight, and excess inventory eat into margins and stretch resources thin. delays and guarantee that critical matters receive the attention they require.

- Damaged Reputation – Chronic delivery failures weaken competitiveness in demanding markets and create long-term brand damage.

When left unchecked, these issues cause companies to devote more energy to damage control than to continuous improvement. Over time, this limits scalability, stifles innovation, and undermines confidence with both customers and employees.

How Escalation Management Software Works

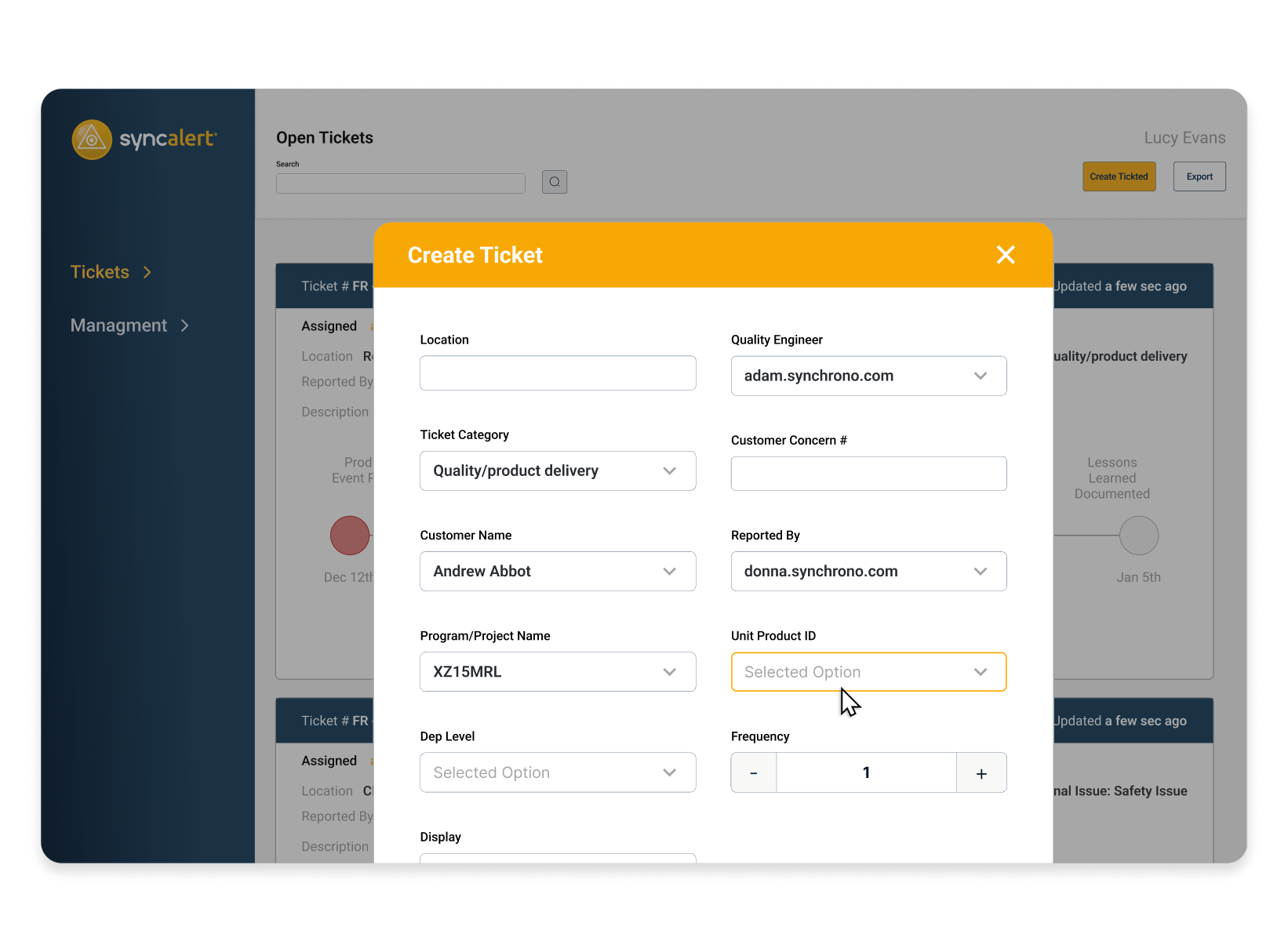

Escalation management software introduces automation and structure into the production issue resolution process. Instead of relying on phone calls, email threads, or manual tracking, manufacturers leverage a centralized system that identifies, assigns, and escalates issues in real time.

Core SyncAlert® Capabilities:

Real-Time Manufacturing Alerts

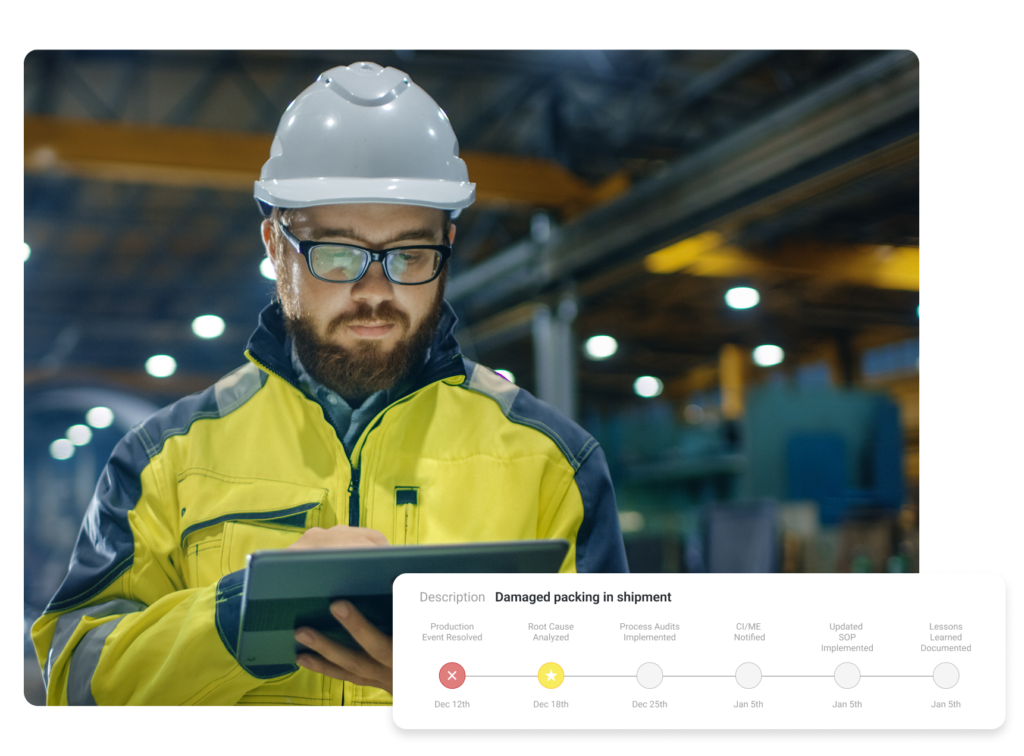

Problems are flagged as soon as they occur, with proactive notifications sent to the right personnel. This instant visibility shortens reaction times and ensures no issue goes unnoticed, even during shift changes or across multiple facilities.

Tiered Escalation Paths

Issues follow predefined workflows, automatically moving to the next level of responsibility if not resolved in time. By creating clear ownership and accountability, tiered paths prevent delays and guarantee that critical matters receive the attention they require.

Integrated Communication

Teams, suppliers, and customers can collaborate within the same environment for faster resolution. This eliminates the confusion of scattered updates, making it easy to align priorities and share accurate, up-to-the-minute information with all stakeholders.

Automated Escalation Workflows

Rules-based triggers ensure critical issues never stall or fall through the cracks. These workflows standardize responses across the organization, reducing dependency on tribal knowledge and ensuring consistency in how problems are handled.

This structured approach ensures accountability, reduces ambiguity, and eliminates wasted time. When paired with solutions like SyncAlert®, escalation processes become a reliable safeguard for maintaining flow and protecting delivery schedules. It also strengthens collaboration between departments, creating transparency from the shop floor to executive management.

Key Advantages of Escalation Management

When companies adopt escalation management software, the benefits are immediate and measurable. Unlike traditional methods that rely on manual tracking or reactive firefighting, automated escalation ensures every issue follows a logical path until resolution.

Faster Response

Address problems before they cascade into delays, protecting on-time delivery performance. By ensuring the right people are notified instantly, production teams can act within minutes rather than hours, preventing small disruptions from escalating into major setbacks.

Improved Reliability

Build credibility with customers by ensuring schedules align with real-world constraints. Consistency in meeting commitments not only strengthens trust but also creates a competitive edge in industries where missed deadlines can mean lost business.

Better Collaboration

Use manufacturing collaboration software to connect teams, suppliers, and customers instantly. This shared environment eliminates silos, making communication seamless and ensuring that everyone involved in the scaling process has the same accurate information.

Reduced Firefighting

Replace chaos with systematic automated escalation workflows that prioritize prevention. Instead of wasting time chasing problems, employees focus on strategic improvement initiatives, creating a calmer, more productive working environment.

Enhanced Visibility

Track patterns and recurring issues to eliminate repeat problems over time. With clear reporting, managers can identify root causes and implement sustainable fixes, leading to stronger process discipline and fewer surprises in production.

Manufacturing Industry Applications

While escalation management is valuable across all manufacturing, some industries benefit most due to the complexity and stakes involved:

- Aerospace – High compliance and strict delivery contracts demand flawless production issue resolution supported by data collection on every production event, enabling analysis to proactively identify potential threats to workflow and velocity.

- Industrial Machinery – Complex assemblies require tight coordination across suppliers and component manufacturers.

- Automotive Tier Suppliers – Just-in-time environments depend on rapid response to disruptions to keep assembly lines moving.

- Defense – Government contracts leave no margin for delays or quality failures, requiring strict escalation logic.

These industries often operate under strict regulations, complex supply chains, and unforgiving delivery schedules. For them, escalation management is more than a best practice—it is an operational necessity that secures customer trust and strengthens competitive advantage.

Connection to Demand-Driven Manufacturing

Synchrono pioneered systems designed to support demand-driven manufacturing, where production follows actual customer demand rather than forecasts. Escalation management is a natural extension of this philosophy.

By aligning alerts and escalation paths with demand signals, manufacturers can quickly adapt to shifting priorities without introducing chaos. This is particularly important in pull-based manufacturing solutions where the flow of materials and work must stay synchronized to real orders.

Benefits of this approach include:

- Shorter Lead Times – Issues are resolved quickly enough to protect order responsiveness.

- Improved Flow – Escalations prevent disruptions from disrupting throughput.

- Resilient Operations – Demand-driven systems remain flexible even under stress.

In practice, escalation ensures that any disruption to flow, whether material shortages or constraint overloads, is managed swiftly and consistently. This enables manufacturers to scale operations while maintaining customer satisfaction.

Why Manufacturers Choose Synchrono

‘For more than two decades, Synchrono has specialized in advanced manufacturing software solutions for discrete manufacturers. Expertise in constraint management, Lean principles, and Theory of Constraints, Synchrono is a trusted partner across a variety of manufacturing industries.

What sets Synchrono apart:

Proven success with escalation management software tailored to discrete operations.

Synchrono has consistently demonstrated measurable results by helping manufacturers streamline production issue resolution, reduce waste, and ensure that every escalation follows a clear, logical path toward escalation.

Seamless integration of SyncAlert® with SyncManufacturing® and SyncView® for enterprise-wide visibility

This cohesive ecosystem connects planning, scheduling, and analytics with real-time alerts, empowering teams at every level to work form a single, accurate version of the truth.

Commitment to long-term partnerships, continuous improvement, and demand-driven principles.

Synchrono collaborates closely with clients beyond implementation, supporting them with ongoing optimization, Lean problem-solving strategies, and adaptation to evolving production challenges.

By combining escalation tools with advanced planning and scheduling, Synchrono helps manufacturers prevent delays, enhance reliability, and strengthen customer relationships. The company’s solutions provide not just technology but also expertise, guiding clients through change management and continuous improvement programs.