Inventory Replenishment Software for Demand-Driven Manufacturing

Inventory Replenishment Software for Demand-Driven Manufacturing

Manufacturers in discrete industries operate in environments where precision, speed, and reliability are critical. Inventory replenishment software helps manage these demands by replacing outdated manual systems with automated, digital workflows.

This technology ensures the right parts arrive at the right place at the right time, eliminating costly interruptions in production. By combining automation with demand-driven replenishment, manufacturers can reduce waste, improve responsiveness, and achieve real-time supply chain visibility.

The Problem with Manual Replenishment

Traditional inventory management often relies on spreadsheets, paper-based cards, or outdated manual methods. These systems are prone to errors, slow to update, and provide little visibility into actual consumption. When a Kanban card is misplaced or a spreadsheet entry is overlooked, the result can be severe: missing parts, halted production, and expensive emergency orders.

Manual replenishment also lacks real-time synchronization. By the time a shortage is discovered, production may already be compromised. Excess inventory is another common problem, as teams often overcompensate to prevent shortages, leading to overstocks that tie up capital and warehouse space.

Key risks of manual replenishment include:

- Lost or Delayed Signals – Manual Kanban cards or paper slips can be misplaced or delayed, leaving suppliers unaware of critical part needs. This creates uncertainty and jeopardizes production schedules. In some cases, suppliers may overproduce as a safeguard, creating additional inefficiencies further down the line.

- Outdated Tracking – Spreadsheets cannot keep up with real-time consumption on the shop floor. As a result, planners operate on incomplete or outdated data, making decisions that fail to reflect current conditions. This lag leads to reactive adjustments rather than proactive planning.

- Costly Consequences – Shortages lead to production halts, while overstocks inflate storage costs and strain resources. Both outcomes weaken competitiveness in fast-moving markets. Additionally, emergency freight and labor overtime only compound the financial hit.

By relying on outdated processes, manufacturers risk higher costs, weaker reliability, and damaged customer trust.

How Automated Replenishment Works

Inventory replenishment software, powered by electronic Kanban systems, transforms replenishment from a reactive process into a seamless, automated workflow. Instead of waiting for someone to notice missing parts, automated replenishment signals are triggered instantly when inventory is consumed.

An electronic Kanban system (eKanban) ensures that signals are delivered reliably and without delays. Every consumption event is recorded, creating immediate alerts that synchronize suppliers, production, and warehouses. By eliminating manual handoffs, errors are reduced and response times are dramatically improved.

Core capabilities include:

- Automatic Replenishment Signals – As soon as parts are consumed, an eKanban system generates replenishment signals, ensuring continuous material flow without human intervention. This eliminates lag time and prevents shortages. Over time, the system also helps manufacturers refine their order quantities to match real-world demand patterns.

- Real-Time Synchronization – Suppliers, warehouse teams, and production facilities share a single source of truth, allowing each group to respond in alignment with actual demand. This coordination is especially valuable in multi-site operations. Consistency across sites ensures no facility is left scrambling to catch up.

- Error Reduction and Speed – Automated signals minimize miscommunication, while digital tracking ensures accuracy in order quantities and timing. The result is a faster, more reliable replenishment cycle. By removing manual guesswork, teams can focus on higher-value activities like continuous improvement.

This approach transforms replenishment into a proactive, integrated process that keeps production running smoothly and efficiently.

Pull-Based Inventory Management in Action

Pull-based inventory management flips the traditional push model on its head. Instead of forecasting demand and pushing materials through the system, pull-based logic ensures that materials flow only when they are consumed.

This approach is foundational to Lean manufacturing inventory practices. By triggering replenishment only in response to actual demand, manufacturers reduce waste, minimize overproduction, and align production closely with customer orders.

Key aspects of pull-based replenishment include:

- Demand-Driven Flow – Replenishment signals are tied directly to actual consumption events, ensuring material flow aligns with real demand. This eliminates reliance on guesswork and reduces inefficiencies caused by inaccurate forecasts.

- Lean Principles – Pull-based logic supports Lean manufacturing by reducing excess, cutting delays, and focusing resources where they are needed most. The practice builds resilience into the supply chain by keeping flow responsive.

- Avoiding Overproduction – Unlike push or MRP software delays, pull systems prevent excess inventory and overproduction, which often burden supply chains with inefficiency. This also reduces carrying costs and frees up working capital.

Pull-based replenishment enables a more agile, efficient system that adapts quickly to changes in customer demand.

Industry Use Cases

Inventory replenishment systems are valuable across many industries. However, they provide the most impact in discrete manufacturing sectors with highly complex supply chains and strict performance requirements. In these environments, precision, responsiveness, and compliance are critical—not just to maintain smooth production, but also to safeguard contracts, regulatory commitments, and customer trust.

Automated replenishment empowers manufacturers in these industries to shift from reactive problem-solving to proactive management, creating a supply chain that adapts as quickly as demand changes.

- Aerospace & Defense – Critical part availability is essential for meeting mission deadlines and maintaining compliance with strict regulations. Automated replenishment ensures readiness and reliability. By integrating real-time alerts, aerospace teams can also improve traceability for regulatory audits.

- Capital Equipment – Complex bills of materials and variable demand make replenishment challenging. Inventory replenishment software provides the agility needed to manage shifting requirements. With automatic signals, capital equipment manufacturers can respond faster to engineering changes.

- Medical Devices – Precision and traceability are essential in medical device manufacturing, where compliance and patient safety drive every process. Automated replenishment ensures that critical components are always available while maintaining complete documentation for audits and regulatory reviews.

- Industrial Machinery – High-volume replenishment cycles demand fast, accurate signals. Automated systems streamline coordination between suppliers and production teams. This reliability supports uptime in facilities where downtime is extremely costly.

- Automotive Suppliers – Multi-tiered supply chains require precision and collaboration. Real-time supply chain visibility ensures just-in-time inventory across multiple partners. Integration with warehouse management systems helps keep assembly lines moving without disruption.

For industries like aerospace, automotive, industrial machinery, and capital equipment, reliable replenishment is not optional. It is a competitive necessity. Automated systems don’t just reduce errors and improve efficiency; they also give manufacturers the confidence to pursue larger contracts, expand into new markets, and meet customer expectations consistently. By transforming replenishment into a strategic strength, companies gain both operational stability and a lasting advantage in highly competitive global supply chains.

Why Manufacturers Choose Synchrono

For over 25 years, Synchrono has been at the forefront of inventory replenishment and demand-driven replenishment strategies. Its systems integrate seamlessly with advanced planning, scheduling, and supply chain management platforms to create a unified digital ecosystem. By combining automation with proven methodologies like Lean and Theory of Constraints, Synchrono delivers solutions that adapt to diverse manufacturing environments while maintaining consistency, compliance, and speed.

What makes Synchrono different:

- Proven Expertise – Decades of success implementing inventory replenishment systems tailored to discrete operations. Clients achieve measurable results such as reduced carrying costs, faster lead times, and more reliable supply chain performance. This proven track record builds confidence for organizations navigating complex, global supply chains.

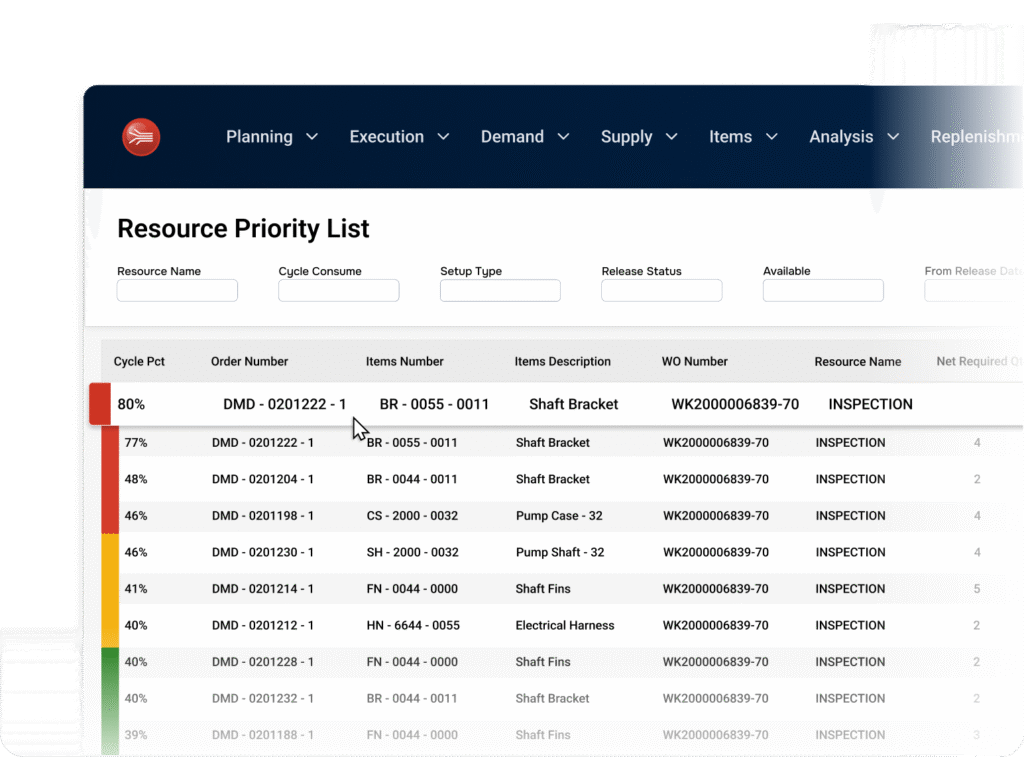

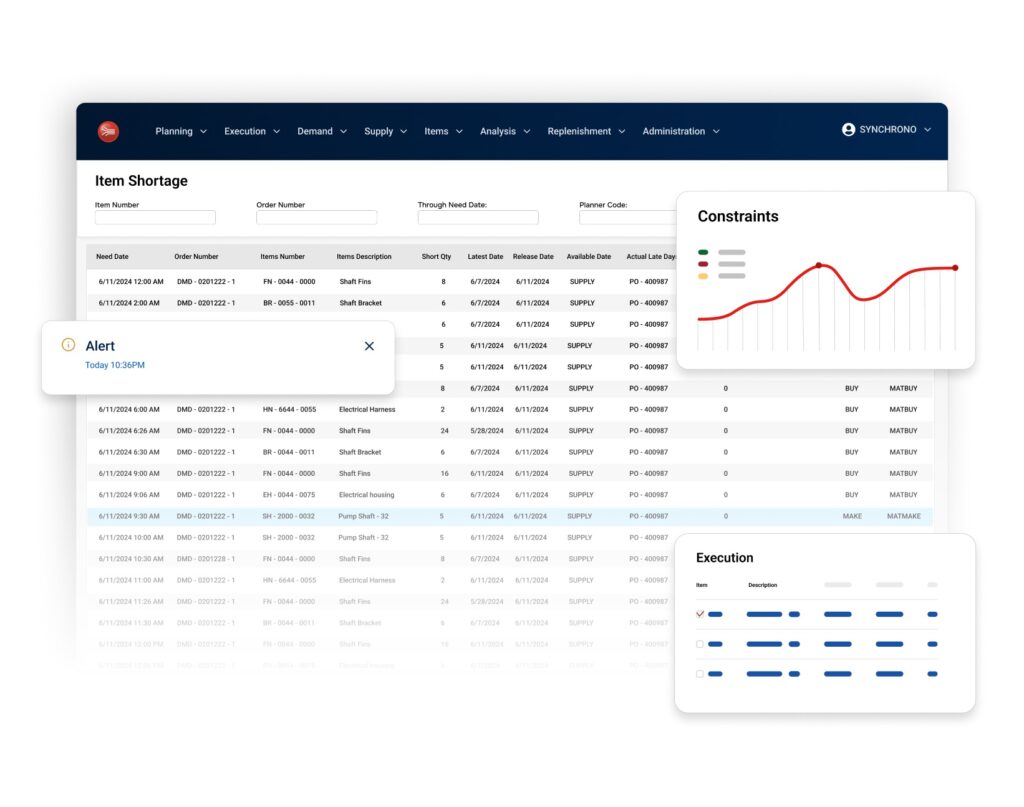

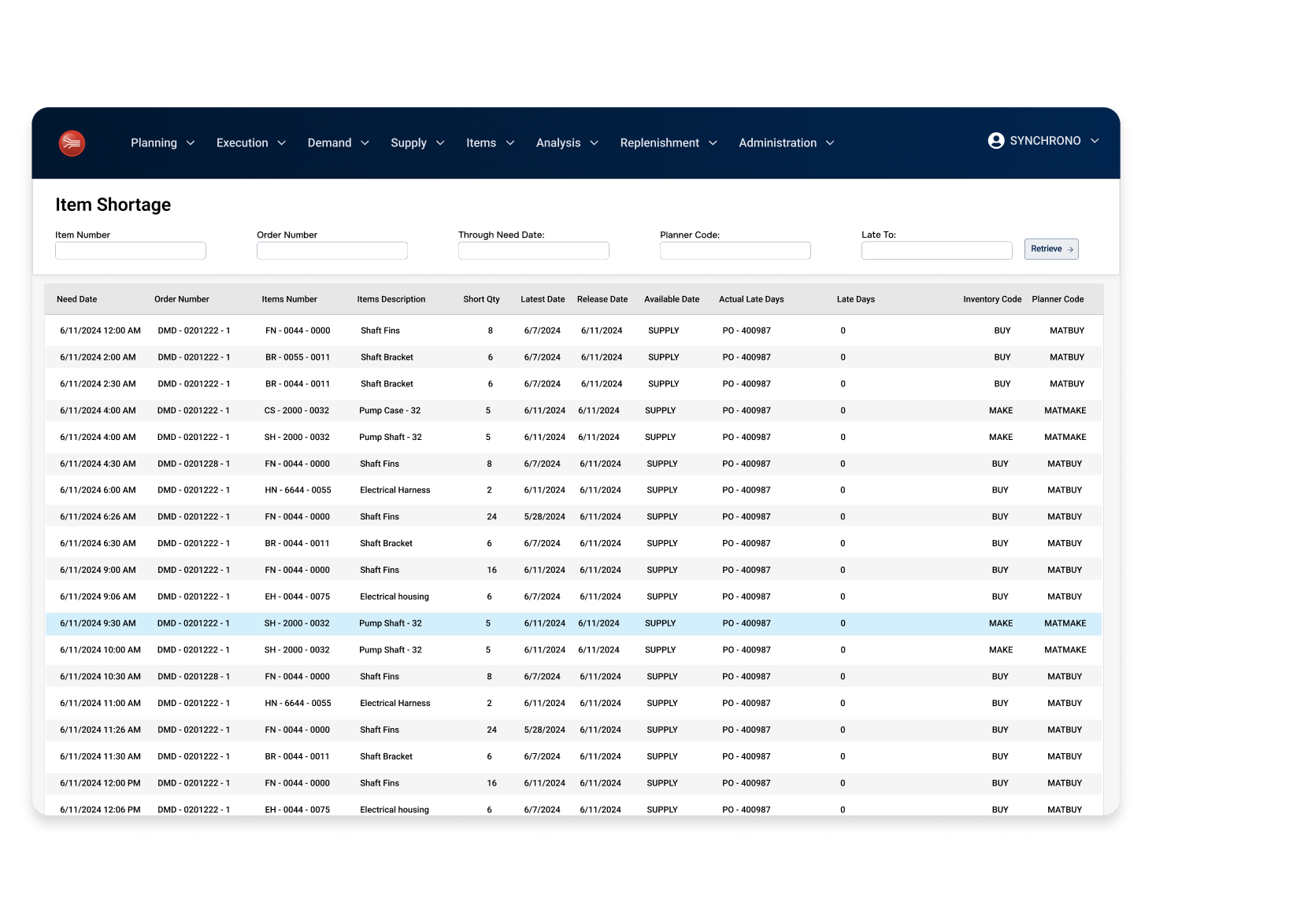

- End-to-End Integration – Seamless connections between SyncKanban®, SyncManufacturing®, SyncAlert®, and SyncView® provide unmatched visibility and control. This unified approach eliminates silos and ensures planning aligns with execution. Manufacturers benefit from a single platform that drives collaboration across departments and accelerates time-to-value.

- Industry Recognition – Recognition as a Gartner Cool Vendor highlights its innovative contributions to manufacturing technology. This distinction reflects a proven ability to deliver real-world results across industries. Industry thought leadership and continuous product innovation further demonstrate our role as a trusted advisor in discrete manufacturing.

- Commitment to Clients – Long-term partnerships, continuous improvement, and Lean problem-solving approaches ensure ongoing success for manufacturers in high-stakes industries. Teams receive ongoing support and guidance that extends well beyond initial implementation. Synchrono consultants work side by side with clients, helping refine processes and achieve sustainable gains year after year.

By aligning automated replenishment with demand-driven principles, Synchrono empowers manufacturers to prevent stockouts and overstocks, enhance collaboration, and scale with confidence. The result is not just a set of tools but a true strategic advantage—equipping organizations to thrive in competitive markets and respond effectively to changing customer needs.