- The Hidden Costs of Excess WIP

- The Root Causes of WIP Accumulation

- Fixing the Flow: Proven Strategies to Reduce WIP

- How SyncManufacturing Enables Greater WIP Control

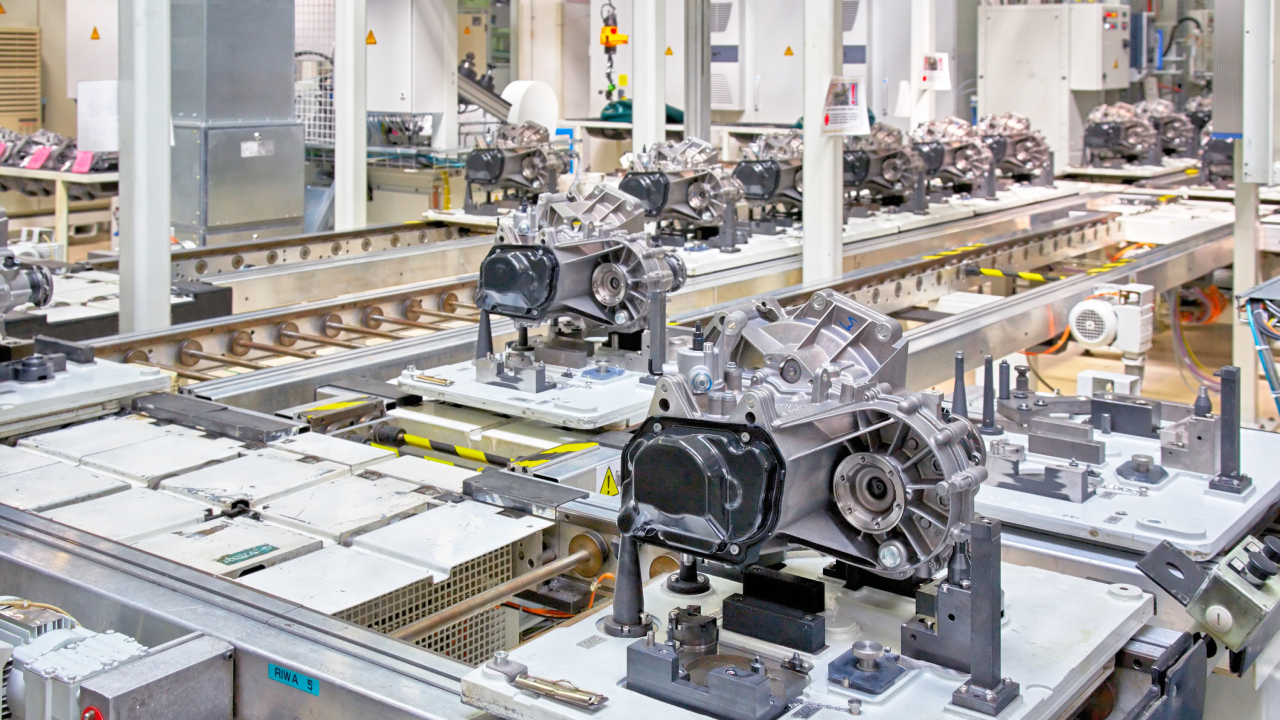

In manufacturing, WIP (Work in Progress or Work in Process) refers to partially finished goods that are at various stages of production but not yet completed. In accounting terms, WIP represents the value of raw materials, labor, and overhead that has been invested in unfinished product. Reducing WIP is a frequently cited goal for many manufacturers as WIP ties up capital and hinders production flow.

In this post, we explore the problems excess WIP causes, the operational issues it can reveal, and how Advanced Planning and Scheduling (APS) systems help manufacturers keep WIP levels under control by creating a stable and reliable manufacturing environment.

The Hidden Costs of Excess WIP

As noted in our introduction, excess WIP creates several issues for manufacturers, making it a prime target for continuous improvement initiatives.

Ties up capital – WIP is a normal component of manufacturing, as all products go through at least some processing. Lengthy cycle times can easily exacerbate WIP issues in complex manufacturing environments. Excess WIP ties up capital as the funds have already been invested, but the completed product cannot yet be shipped.

Increases storage and handling costs – WIP also takes up space, which can contribute to increased storage and handling costs. Excess WIP can also increase scrap costs as unfinished components that are moved around to make room for other production orders or inventory can easily be damaged or misplaced.

Longer lead times – Excess WIP is often a symptom of process issues, such as over releasing work, poor flow, and process misalignment. If production orders aren’t properly prioritized and scheduled, excess WIP in the pipeline increases wait/queue times, leading to longer lead times and missed delivery dates.

Difficult to Manage – Having too much WIP makes it much more difficult to manage the production process. Excess WIP leads to wandering bottlenecks, increased batching, increased expediting, and a higher likelihood of resources running incorrect work. The more WIP in the system, the more orders to keep track, the more difficult it is for management to ensure focus remains on the highest priority work

The Root Causes of WIP Accumulation

Excess WIP is a telltale symptom of deeper operational problems rooted in misaligned philosophies, inefficiencies, or poor planning. Here are several root causes of excess WIP in complex manufacturing environments.

Push-Based Production Philosophy – The classic example of a push-based system is one that schedules production based on forecasts and pushes production through the process regardless of downstream processing capacity and actual customer need. Products are manufactured in advance, assuming demand will consume the supply. Poor forecasting and disconnects between production and actual customer demand lead to overproduction, a key driver of excess WIP.

In addition, in both make-to-forecast and make-to-order environments, push-based production increases WIP when work is released or started upstream without sufficient regard for the pace or capacity of downstream processes. This allows semi-finished goods to pile up at intermediate stages, drastically increasing queue times, until capacity becomes available. Constant expediting, changes in customer demand, and downstream bottlenecks further amplify the problem.

Batch Planning – Batch planning involves processing materials or components together in a “batch” rather than one at a time in a continuous flow. Larger batch sizes increase WIP because products must travel in bulk, waiting until the entire batch is ready before moving to the next step. If equipment or processes are delayed downstream, the entire batch is held up, further compounding the accumulation of WIP across stages. Changeovers or scheduling mismatches can also create periods where WIP sits idle between processes, waiting for subsequent operations.

Poor Constraints Management – Even when a push-based production philosophy isn’t followed, poor constraints management creates similar issues. When work is released to production and upstream processes produce at full capacity regardless of the constraint’s capacity, WIP piles up in front of the constraint, roving bottlenecks occur at the non-constraints, and overall throughput is reduced.

Misaligned and/ or Outdated KPIs – Key Performance Indicators (KPIs) are used to measure system performance, but if they incentivize the wrong behaviors, they can be counterproductive. This is especially true of KPIs like “machine utilization” or “line efficiency” that prioritize keeping equipment running at full capacity rather than focusing on overall system. Additionally, if production teams are incentivized to produce as much as possible without regard for demand or system constraints, WIP will accumulate unnecessarily.

Batch Planning with a Focus on Local Optimization – Closely tied to the issue of misaligned KPIs, local optimization occurs when individual departments or production zones prioritize their own efficiency over overall operational efficiency. This can lead to departments producing large batches or components ahead of time to avoid setup costs or to meet their own output targets. These efforts to maximize efficiency within one department often lead to mismatches elsewhere, missing parts at downstream convergence points, inconsistent work availability at subsequent work centers causing delays, inefficiencies, and excess WIP throughout production system.

Fixing the Flow: Proven Strategies to Reduce WIP

Addressing WIP buildup typically requires implementing lean principles, such as pull-based systems (e.g., Kanban), optimizing constraints (Theory of Constraints), reducing batch sizes, and using KPIs that reflect overall system performance rather than local optimization. The goal should always be to enable a smooth, synchronized production flow that minimizes waste while meeting actual demand. Within Lean and TOC are several frameworks that directly address the issue:

Just-In-Time (JIT) – JIT is a manufacturing methodology that aims to reduce waste by producing goods only as they are needed for the next phase of production or for customer delivery. By aligning production schedules closely with actual sales or downstream usage, JIT minimizes the time WIP spends queuing between each step. While production runs are typically smaller under JIT, this means fewer items are in the system at any given time and only what is needed is being produced.

While not synonymous, JIT is often a feature of Lean manufacturing environments as pull system techniques like Kanban are leveraged to create a workflow where production is “pulled” by consumer demand rather than “pushed” based on forecasts.

Implementation Best Practice

We’ve seen many JIT initiatives go wrong when the manufacturer tries to push ahead too fast. They immediately eliminate almost all inventory, anticipating immediate improvements. The best success is achieved when JIT is implemented as an incremental process:

- Start by reducing (not eliminating) inventory levels in one area of the business.

- Monitor the system to identify issues caused by the reduced inventory.

- Address the issues identified in step 2, then repeat the process starting at step 1.

Each time through the cycle will yield incremental performance benefits while minimizing business disruptions.

Theory of Constraints (TOC) – TOC states that there is generally one or a limited number of constraints (the weakest link) in any system at any given time. Production should be synchronized to these constraints. Failure to identify and manage constraints properly can lead to excessive WIP throughout the system, hindering material flow and increasing lead times.

Value Stream Mapping (VSM) – VSM is another tool used in Lean manufacturing to visualize and analyze the flow of materials and information required to bring a product or service to the customer. Identifying all the steps in a value stream makes it easier to see where WIP is piling up and why.

Waste Reduction – A fundamental principle of Lean, waste reduction involves eliminating anything that does not add value for the customer. JIT and VSM are useful tools for identifying excess waste. In addition, Kaizen events, where employees at all levels of an organization work together to proactively identify potential improvements to the manufacturing process, can also help reduce WIP.

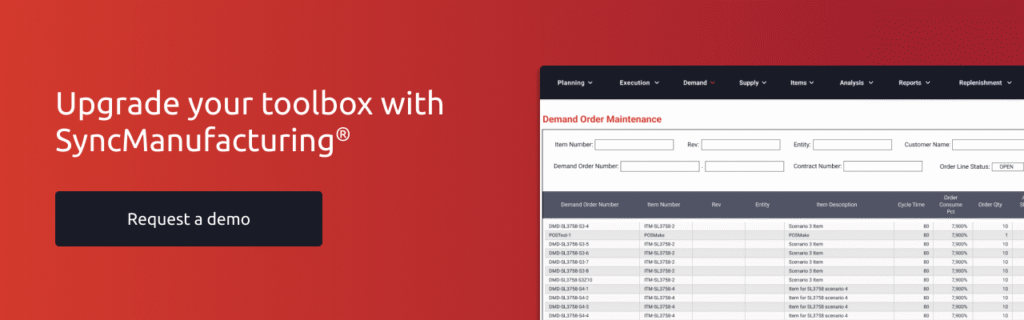

How SyncManufacturing® Enables Greater WIP Control

Technology plays an important role in implementing continuous improvement philosophies such as Lean Manufacturing and TOC. SyncManufacturing APS is our customers’ control tower for implementing proven, demand-driven processes that lower WIP and improve flow. Here’s how it works:

Finite capacity scheduling: Most ERP systems create production schedules based on material availability but assume infinite factory capacity. SyncManufacturing leverages finite capacity scheduling (also known as finite capacity planning) to create production schedules based on the actual availability and capacity of resources, including machines and personnel. Production schedules at upstream resources are optimized for capacity downstream. This minimizes queue times and smooths the flow of materials and WIP through the factory.

Real-time demand-driven scheduling: While SyncManufacturing can be used in a make-to-stock environment, many of our customers leverage our APS system to move towards true demand-driven manufacturing. As customer orders come in, SyncManufacturing uses real-time resource availability and capacity data to produce realistic capable to promise dates. When orders are accepted, schedules are updated and resources are allocated to the job.

Dynamic scheduling: SyncManufacturing adjusts and updates production schedules in real-time based on changes in the production environment, such as equipment downtime, material shortages, or changes in demand. This adaptability ensures that the flow of work remains efficient and prevents bottlenecks, which can lead to excess WIP.

Global flow optimization: SyncManufacturing aligns all production activities to ensure a seamless flow of materials and tasks across the entire value stream. By analyzing and optimizing the overall system rather than individual processes, it balances production loads and eliminates unnecessary buildup of inventory and WIP.

Constraints management: CONLOAD™ is our proprietary algorithm for managing constraints effectively. The most critical resources (constraints) are identified, and the amount of work released into the system is controlled based on these constraints to minimize queue times, improve flow, and decrease WIP.

Real-time visibility and decision support: SyncManufacturing provides real-time visibility into every aspect of the production process using dashboards and integrated monitoring tools. This allows manufacturers to monitor WIP levels, identify bottlenecks, and make informed decisions instantly. Decision-support tools include predictive analytics and alerts, which help manufacturers proactively address potential issues before they escalate.

Do You Have Too Much WIP?

Excess WIP is more difficult to hide than other inventory management issues. Data trends like increasing queue and cycle times or decreasing inventory turns are good indicators of WIP that is becoming bloated. Production managers may also walk around the production environment and spot piles of work sitting in front of workstations or teams sitting idle as they wait for materials.

This excess WIP may be costing you more than you think! Contact us or schedule a personalized demo to see how you can improve and get rid of excess WIP to cut costs and improve production flow.