Driving Continuous Improvement.

Driving Continuous Improvement.

In Demand-Driven Manufacturing, there is only one measurement that is important to drive performance: Throughput. There are two subordinate measurements: Inventory and Operating Expense. These three measurements cover the gambit of what needs to be measured because they are directly related to customer orders, cash captured inside the organization, and the cash it takes to turn inventory into sales.

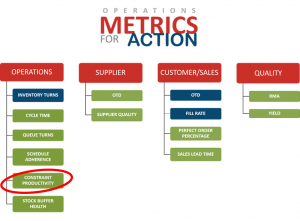

Demand-driven managers know that having too many metrics leads to conflicting measurements. From a Demand-Driven Manufacturing operations perspective, you want to pay strict attention to strategic control points for improving Throughput. We call these Metrics for Action.

Metrics for Action

Metrics for Action are not intended for overall business analysis or for simply reporting. Rather, they are metrics grounded in Lean Manufacturing, Constraints Management, and Six Sigma principles that serve as operational indicators that can be acted on to improve production flow and ultimately, Throughput.

Example: A specific actionable metric for Demand-Driven Manufacturers is Constraint Productivity; a metric that determines whether a constraint resource is operating at its optimal capacity. Manufacturers monitoring Constraint Productivity want to get to the point where they are releasing work onto the shop floor at a rate that equals the constraint resource’s optimal production level. This is the pace at which the constraint keeps flow moving throughout the entire production process. Think of it like a metered freeway entrance ramp – your car is let on to the freeway at a rate where you can easily merge and traffic keeps flowing. Without the meter, there would likely be a traffic jam, impacting everything up and down-stream.

Ultimately, the constraint is the pacemaker of the system, so by understanding Constraint Productivity, you understand the flow of the entire system.

Alignment Between Metrics for Action and Continuous Improvement

Sustainable metric improvements require a continuous improvement methodology—a cycle that is never fully complete. Continuous improvement (also referred to as Kaizen) is a process for becoming increasingly competitive by improving efficiency and quality through systemic, incremental changes. In demand-driven environments, continuous improvement efforts look to address the most significant disruptions to production flow. Toward that end, Demand-Driven Manufacturers monitoring Metrics for Action have a leg up. The goal of this concise set of actionable metrics is to provide real clarity around the elements that drive flow – and to quickly make adjustments to improve organizational excellence and enhance demand-driven results.

Example: If you applied a continuous improvement process to the Constraint Productivity example, you would work to understand the capacity of the constraint(s) and adjust the pace until you’ve achieved an optimal rate of flow (e.g., end-to-end production flow). In doing so, you may also create a competitive advantage in your market through improved lead times and/or increased capacity.

Example: If you applied a continuous improvement process to the Constraint Productivity example, you would work to understand the capacity of the constraint(s) and adjust the pace until you’ve achieved an optimal rate of flow (e.g., end-to-end production flow). In doing so, you may also create a competitive advantage in your market through improved lead times and/or increased capacity.

Like Demand-Driven Manufacturing itself, Metrics for Action are based on synchronization and managing constraints to drive flow. Improvements in these areas lead to improvements in the core metrics of Throughput, Inventory and On Time Delivery which in turn, leads to improvements in other key areas. Are your metrics really working for you? We welcome your comments – and any examples you have of how you’ve used actionable metrics.

Additional resources:

White paper: Demand-Driven Manufacturing Metrics for Action provides additional background on Metrics for Action and examples.

Article: CONLOAD™ is a software scheduling algorithm that will determine the pace of constraint resource(s) and automatically release work into production at an optimal rate to keep production constantly flowing.