Blog

-

Real-Time Inventory and WIP Visibility for Discrete Manufacturing

Real-time inventory visibility gives discrete manufacturers a live, trusted view of material availability and work-in-process (WIP) across the plant. Instead of relying on static ERP reports, teams see inventory status as it changes, supporting better scheduling decisions, smoother execution, and more reliable delivery performance. By connecting inventory and WIP data to production priorities, manufacturers can

-

How Johnstech Reduced Lead Times by 50%

The semiconductor industry is competitive, with efficiency and reliability being paramount for success. Johnstech International has consistently delivered results that surpass industry standards, most notably achieving a remarkable reduction in lead times to just 3-4 weeks, compared to the typical industry standard of 5-8 weeks. This achievement underscores their use of advanced planning, scheduling, and

-

Advanced Cybersecurity: How NIST 800-171 Compliance Raises the Bar for Data Protection

Cyberattacks are growing in frequency and sophistication, targeting organizations of every size and in every industry. For manufacturers that rely on digital systems to deliver products, support customers, and safeguard intellectual property, a single breach can trigger financial losses, downtime, and lasting damage to brand trust. As a result, cybersecurity has shifted from a back-office concern to a board-level priority. Choosing systems that

-

Strategic Prioritization: The Manufacturing Leader’s Guide to Operational Excellence

Manufacturing organizations face an uncomfortable truth: having the capacity to produce something doesn’t mean you should. Every resource allocation decision—from accepting sales orders to scheduling production runs—directly impacts your bottom line. Without strategic prioritization driving these decisions, even the most sophisticated manufacturing operations can spiral into inefficiency, missed deadlines, and diminished profitability. Strategic prioritization extends far beyond simple task management or

-

Efficiency vs. Productivity: Metrics that Matter…Until They Don’t

Measure efficiency and productivity against your REAL goal I keep seeing the word efficiency in manufacturing media. As someone who specializes in Constraints Management, this term is particularly vexing. It’s one of those words that I believe should be used with extreme caution. When we look at the organizations of today, words like efficiency and

-

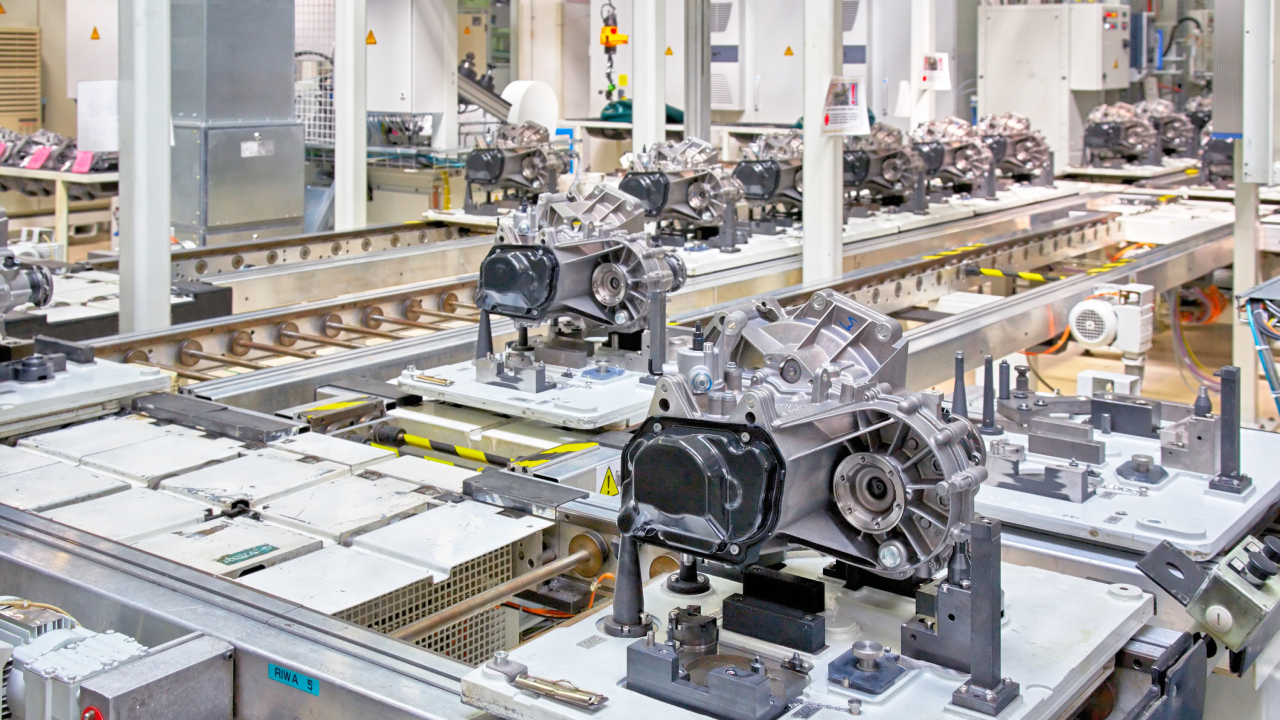

The Devastating Impact of Too Much WIP: How Excess Inventory Kills Manufacturing Flow

In manufacturing, WIP (Work in Progress or Work in Process) refers to partially finished goods that are at various stages of production but not yet completed. In accounting terms, WIP represents the value of raw materials, labor, and overhead that has been invested in unfinished product. Reducing WIP is a frequently cited goal for many