Engineering design fiascos – spending thousands to save pennies

This is a true story. The names have been changed to protect the innocent. It’s meant to illustrate how using constraints-based thinking can uncover the hidden price of cost-cutting projects.

Several years ago, a friend of mine was working in the quality group at a large automotive company. We will call my friend Harry for the story. Harry’s position was to use statistical analysis to determine design flaws from a large data warehouse containing warranty data, recall data and state-by-state accident information collected about the products the company manufactured. This data was used to identify areas where leading indicators could prevent major recalls and point out where engineering might improve products. Although this effort was important to the organization, Harry thought that there were better ways to move the company ahead faster than looking at data from the past, which in many cases, was a byproduct of compromises in the design process.

After many years of working in the quality group, Harry decided to contact the CEO of the company. Harry felt that if they were to look at the issues and conflicts in new product development and in product design engineering, the company would be able to eliminate the design compromises, which led to the negative effects of recalls and warranty costs.

To Harry’s surprise, he received a response from corporate leadership and from an engineer named Edwin. Edwin was the Director of Engineering and Competitive Practices for the organization and was responsible for identifying methods or systems that competitors were using, and determine which should be adapted to benefit the company. Edwin wanted to know if Harry’s recommendation was possible, and arranged a meeting.

A fateful meeting

Another colleague with the company and I were lucky enough to be invited to the meeting with Edwin and Harry. The conversation started with questions and answers about the current process for new vehicle design. We were all interested in learning how new improvements to current models came about in the company.

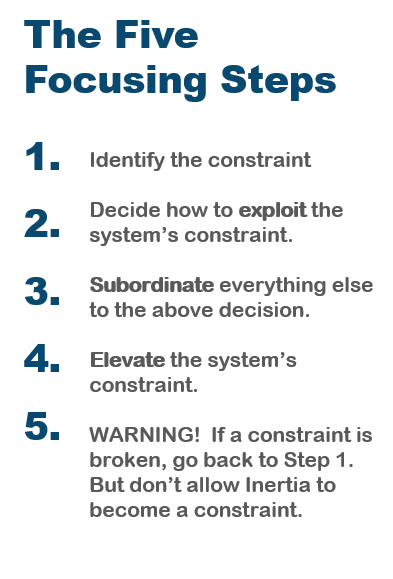

Edwin told us that during a new design, his group had little influence on the timeline, which would be handled by some other part of the organization. So, we asked for an example of how engineers were introduced to this process. Since Harry and I are Theory of Constraints Jonahs (A Jonah is someone who uses the socratic approach to problem resolution), we wanted to understand the baseline for the process and find out what they considered to be a successful project. We also wanted to learn how they chose products and measured performance. Edwin told us that the number one measurement was cost savings on an assigned project.

We were told that the group manager’s annual goal was to reduce component costs on each vehicle, for example, by $0.04/vehicle on a vehicle platform. In one case, the engineer looked at reducing the cost of the door locking system by $0.01 to $0.02. If the car is a 4-door, they would hit their cost-savings target over the total of vehicles they made that year. These goals are typically in the $400,000 to $5,000,000 range across the entire vehicle line.

An engineer redesigned the door-locking mechanism to reduce the cost of the components in the car — and sold the group’s idea to management. After some back and forth between various levels of the organization, the project was approved, and design money and resources were budgeted.

We asked several questions to determine if this was, indeed, a cost savings. Here’s what we learned from Edwin:

Q: How many door locking mechanisms does the company currently use?

A: Seven.

Q: If there is a new design, is one taken out of service?

A: Not usually; not until it is determined to be obsolete. Warranty and Service have a large influence on the determination of obsolescence.

Q: Since this is a door-locking mechanism, will the vehicles that use this new design have to be sent through crash testing to determine if the new device meets safety standards?

A: Yes.

Q: More than just the normal yearly testing?

A: Yes, since it was a change to a safety device, extra testing will be required to ensure the design meets or exceeds standards.

Q: Do the suppliers of the mechanisms need to fill the supply chain with parts so the new design can be used in production?

A: Yes, the suppliers would have been working with the design team during the process, so they would know what the supply chain needs to be prepared for production. They are very good about keeping up with the design process.

Q: With a new design, how often is it ready on time for assembly to begin the new model year?

A: There are frequent delays for the new model year, and there will have to be some work to change over the new mechanism.

“I’m sorry, but I do not see how there is any cost savings in the method you described,” I said.

They answered, “Of course there is, the company saved $0.02 per vehicle!”

I explained that because the process described added a new assembly, each step represented new inventory to support the new assembly. Since the old design wasn’t discontinued, the inventory for the old design would not be removed from the system, so no savings there. If the new design is not ready for the model year changeover, the delay to production can be quite costly, the old parts would have to be used until the new parts are available, and then the old inventory would need to be removed, new inventory added and the assembly line would need training. In addition, the dealership network would have to be notified about when the old style was changed and in which vehicles. The dealership technicians would also need training on the new mechanism.

Every step costs

Every step they took added cost. Their $0.02 savings was eaten up before they began. In reviewing the entire process, we quickly realized that no one at the company had a holistic view of the process. Further, they didn’t have any comprehensive information to fully judge the impact of a change upon the system due to the silos and structure of the organization.

Edwin maintained that because they were measured for the $0.02 cost savings, they only needed to concentrate on that– they did not have any knowledge or responsibility for what the rest of the company was doing.

I simply said, “I think you are using the wrong measurements.”

On my way back from the meeting, Harry said, “What do you think is the number one warranty cost for the company?”

“I don’t know, please tell me,” I said.

“Door locking mechanisms,” he answered. “How about in the 1990s?”

“The same?” I asked.

“Yes,” he added. “In fact, the number one warranty item since the 1960s has been door locking mechanisms.”

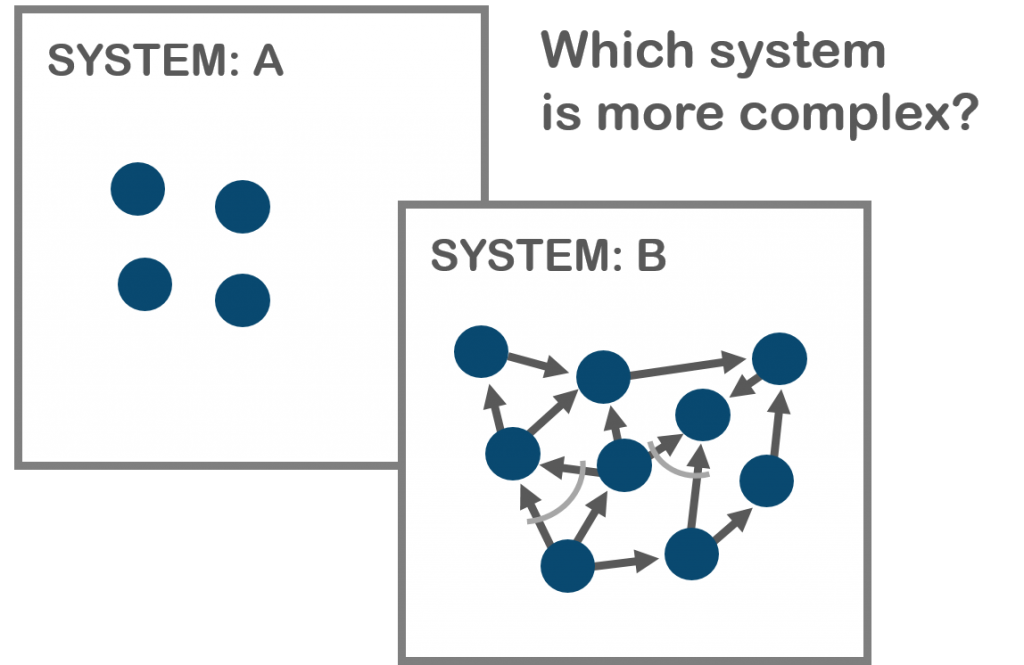

He went on to tell me that in the late 1980s, the company did a study between its door lock mechanisms and another car manufacturer’s design. At that time, Harry’s company’s door lock had 13 parts in the design compared to 7 parts in the competitor’s lock mechanism. Fewer parts are often more cost-effective—as there is less time to assembly them, fewer parts in the supply chain, and simplicity is its own form of effectiveness.

The company they used for the study was well known for their impressive reputation for quality. Keep in mind, he said– each new engineer goes through a required training course that uses this comparative study to show the differences between Harry’s company design and the premier competitor’s design. The objective is to reduce complexity and still provide world class quality. And, these engineers need to demonstrate that they understand the study and its implications for the company before they are allowed to do any design work.

“We have been teaching this class for 15 years. Do you know how many parts our current design has?” Harry asked me.

“I would guess eight or nine?” I looked at him hopefully.

“No,” Harry sighed. “We have 12 parts in our design and the competitor’s mechanism is now using 6 parts.”

I didn’t know what to say to that, other than shake my head in dismay.

Epilogue

That was 10 years ago. Since then, there have been several senior leadership changes at the company. And even though that company, like many others, further fractured into a flatter organization, it maintains many of the traditional silos.

This company eliminated or sold many vehicle lines to preserve cash to strengthen the parent company. And, after a long and hard struggle, they are again profitable. The company is making a better quality vehicle today, but the number of recalls is still higher than the global average for the same type of organization.

Many organizations still focus on cost savings to the detriment of a holistic view of constraints. They base design and engineering decisions on what looks like it will save money rather than the costs of instituting these changes. Next time, we will talk a bit about why erroneous metrics make projects like the $0.02 -savings door lock look good. Let me know about your experiences with constraints management—or share a story like this one. I’d love to hear from you.

– Rick Denison

Rick is the “Dr. Who” of manufacturing operations and logistics. And while Rick doesn’t travel through time, he is adept at leading change – and saving time – in a diverse range of manufacturing environments through Lean manufacturing, Six Sigma, and TOC techniques. Rick’s posts address how demand-driven matters and draws from his background in process improvement, change management, project management, information systems implementation, and profitability analysis.

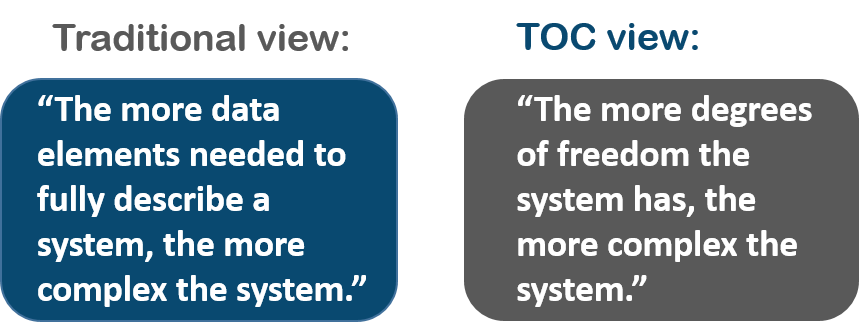

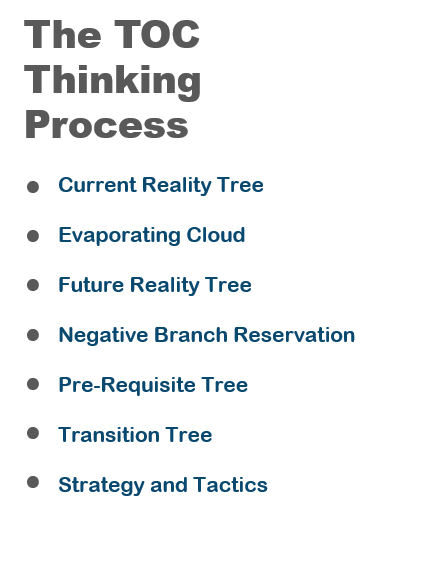

This causal relationship is used to describe the current reality of a system. The effect-cause-effect technique allows TOC Thinking Process experts to significantly reduce the number of elements that they must touch to influence the entire system. The degree of freedom in the system is defined as the number of items in the system that need to be touched to effect the overall system. In this way, an interconnected system is much simpler.

This causal relationship is used to describe the current reality of a system. The effect-cause-effect technique allows TOC Thinking Process experts to significantly reduce the number of elements that they must touch to influence the entire system. The degree of freedom in the system is defined as the number of items in the system that need to be touched to effect the overall system. In this way, an interconnected system is much simpler. However, all systems can be described by this process. Once completed, you’ve uncovered the inherent simplicity of the organization.

However, all systems can be described by this process. Once completed, you’ve uncovered the inherent simplicity of the organization.