A new study in Modern Materials Handling reports that 86% of industrial organizations are currently adopting IoT (Internet of Things) solutions, and 84% believe those solutions are very or extremely effective. Manufacturers lagged behind the industrial segment as a whole, with only 77% of manufacturers implementing IoT in their facilities.

So, what is holding manufacturers back? Anecdotally, I can share that many of the manufacturers I talk to intend to implement the IoT in their facilities or have already started a project. But, they are less sure about their results than the respondents to the study.

In this series of posts, our goal is to break through the hype and the uncertainty around the IIoT (Industrial Internet of Things) by focusing on projects you can execute and for which you can achieve a measurable ROI in 2018.

In the first post, we looked at how the IIoT can help manufacturers lower inventory levels. (Read the full post here.) We also shared how one of our customers was able to reduce inventory by as much as 55% in one factory, while at the same time reducing lead times from twelve weeks to two.

Some of the customers I talk to are initially skeptical that they can both reduce inventory AND reduce lead times. Achieving these results at the same time seems counter-intuitive because they think they need to keep high levels of inventory on hand and in process to meet customer demand. In today’s post, I want to unpack that by focusing on how the IIoT and Demand-Driven Manufacturing (DDM) can help you achieve both objectives in your facility by implementing one specific manufacturing philosophy.

The IIoT in action: TOC

Today’s IIoT project leverages the Theory of Constraints (TOC) or constraints management principles. Like the Kanban project we talked about (see How the IoT Can Help You Lower Inventory Levels), TOC isn’t inherently an IIoT project. You can implement TOC manually, but when IIoT data-sharing technologies are leveraged, your TOC efforts are turbocharged for even greater benefit to your bottom line.

Many of you are, no doubt, familiar with TOC, but let’s quickly cover what it is so we’re all on the same page. TOC says that, in any given manufacturing environment, there are a small number of constraints that limit the throughput of the factory. Increasing productivity at any other point in the system will not increase overall productivity because the constraint cannot keep up.

For more details on the four types of constraints, refer to my recent post: It’s Time to Revisit Your Constraints.

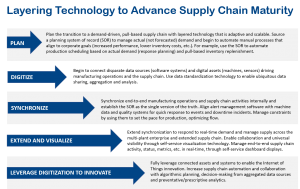

In the Demand-Driven Manufacturing environments we work in, we apply constraints management technology (based on TOC) to constraints in the system. By understanding the constraints – and their capacity – we can set the optimal rate of flow to that constraint (see CONLOAD™ Scheduling Methodology: Set the Right Pace for Production). This reduces congestion and keeps work flowing throughout production. Real-time, IIoT data allows for automated adjustments based on changes in demand, priorities, etc.

So how does synchronizing the pace of production to the constraint in real time lower both lead times and inventory levels? In a traditional make-to-stock manufacturing environment, as much as 90% of cycle time is queue time, that is, a part waiting for its turn on the machine or in the work center. By synchronizing the flow of material to the constraint in the system, material spends less time in queue and cycle times are shorter. And, because less material is in queue, WIP drops as well.

Related Post: It’s Time to Revisit Vendor Managed Inventory

Some of you may be thinking, “Ok, that explains how cycle times and WIP inventory drop, but how does constraints management affect lead times? We measure lead time from the time an order is taken until it is shipped. I still can’t manufacture anything faster than my constraint, and it doesn’t lower lead times if I can’t start the order any faster.”

Good point. But, what we’ve found is that lead time typically drops as well for a variety of reasons such as better prioritization of projects at the constraint and increased capacity. When all work throughout the facility is synchronized to the pace of the constraint, everyone knows what they need to do next, and no time is wasted running orders through the system that aren’t a priority. This is especially impactful in facilities where changeovers take time either because of retooling or a paradigm constraint, such as a focus on productivity at every workstation that slows the overall factory down.

impactful in facilities where changeovers take time either because of retooling or a paradigm constraint, such as a focus on productivity at every workstation that slows the overall factory down.

In my last post, I shared the example of Dynisco, a leading manufacturer of materials-testing and extrusion-control instruments that reduced inventory levels by 55% in one of its facilities while at the same time reducing lead time from 12 weeks to 2. Today, I want to tell you about another Synchrono customer that addressed a lead time issue with Demand-Driven Manufacturing.

Rex Materials Group (RMG) manufactures custom vacuum-formed ceramic-fiber products. In the late 1990s, the company implemented TOC and modified its home-grown systems to apply drum-buffer-rope principles. That system worked for a while, but eventually, the company decided they needed something better to feed their continuous improvement efforts.

RMG implemented SyncManufacturing™ synchronized planning, scheduling and execution software from Synchrono® across three separate facilities. The first facility went live in 90 days and the second and third in 45 days each. By accelerating their TOC efforts, RMG went from lead times of three to four weeks, on average, to delivering 30-40% of products within five days of receiving the order. They can even ship some overnight. Read the full case study.

Want to learn more? Here are some related resources that can help you get started on your next IIoT project in 2018:

Video: What is Demand-Driven Manufacturing?

White Paper: Three Key Strategies of Modern Demand-Driven Manufacturing (Watch the video here.)

Video: Manage Manufacturing Constraints and Optimize Production Flow with CONLOAD