Category: Constraints Management

-

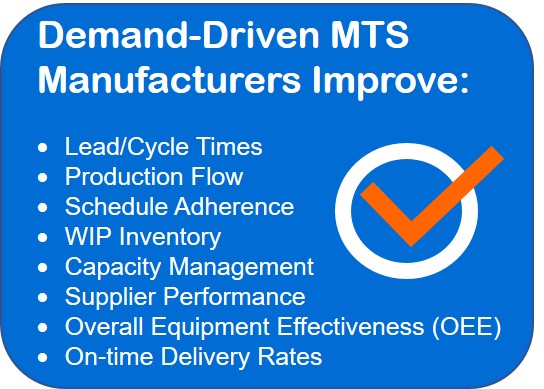

FAQ: Can I Use Demand-Driven Manufacturing in a Make-to-Stock Environment?

Demand-Driven Manufacturing seems like it was made for Make/Assemble-to-Order and Engineer-to-Order environments. It’s true that Demand-Driven Manufacturing can be beneficial for manufacturers who already produce goods based on customer demand because it improves their responsiveness to customers and lowers lead and cycle times. Demand-Driven Manufacturing is a method of manufacturing where production is based on

-

Why Demand-Driven Manufacturing is Focused on Metrics for Action

Driving Continuous Improvement. In Demand-Driven Manufacturing, there is only one measurement that is important to drive performance: Throughput. There are two subordinate measurements: Inventory and Operating Expense. These three measurements cover the gambit of what needs to be measured because they are directly related to customer orders, cash captured inside the organization, and the cash

-

Demand-Driven Technologies Evolved

By John Maher When I first began instituting demand-driven practices in the late 90s, we were into creating pull, eliminating waste, and getting on a path of continuous improvement. Technology at the time was seen as an inhibitor rather than an enabler. Most people active in Constraints Management and Lean Manufacturing were abandoning their technology

-

Smooth the rough spots with TOC, then Lean – and fine-tune with Six Sigma

What Grade of Sandpaper Will You Use? Part Four Here we are at the final installment of our four-part, Sandpaper blog series about when to use the tools of Lean Manufacturing, the Theory of Constraints (TOC) and Six Sigma to address constraints, drive flow and promote continuous improvement. With regard to sandpaper, I talked a

-

Common Lean Manufacturing Software Project Constraints

Leveraging Project “Constraints” and Maximizing Results As a project manager for demand-driven, lean manufacturing software, I have more than a nodding acquaintance with the theory of constraints (TOC). What I find quite remarkable is the ability to apply the theory of constraints to other

-

Using TOC, Lean and Six Sigma to Become More Demand-Driven

What Tools to Use to Get the Most of Your Demand-Driven Changes Last time, we looked at specific companies that I have worked with and how they became more demand-driven using the Theory of Constraints (TOC) as a first step. As you saw from these real-life examples, TOC works well as a pointer to see