Category: Lean Manufacturing

-

Real-Time Inventory and WIP Visibility for Discrete Manufacturing

Real-time inventory visibility gives discrete manufacturers a live, trusted view of material availability and work-in-process (WIP) across the plant. Instead of relying on static ERP reports, teams see inventory status as it changes, supporting better scheduling decisions, smoother execution, and more reliable delivery performance. By connecting inventory and WIP data to production priorities, manufacturers can

-

Efficiency vs. Productivity: Metrics that Matter…Until They Don’t

Measure efficiency and productivity against your REAL goal I keep seeing the word efficiency in manufacturing media. As someone who specializes in Constraints Management, this term is particularly vexing. It’s one of those words that I believe should be used with extreme caution. When we look at the organizations of today, words like efficiency and

-

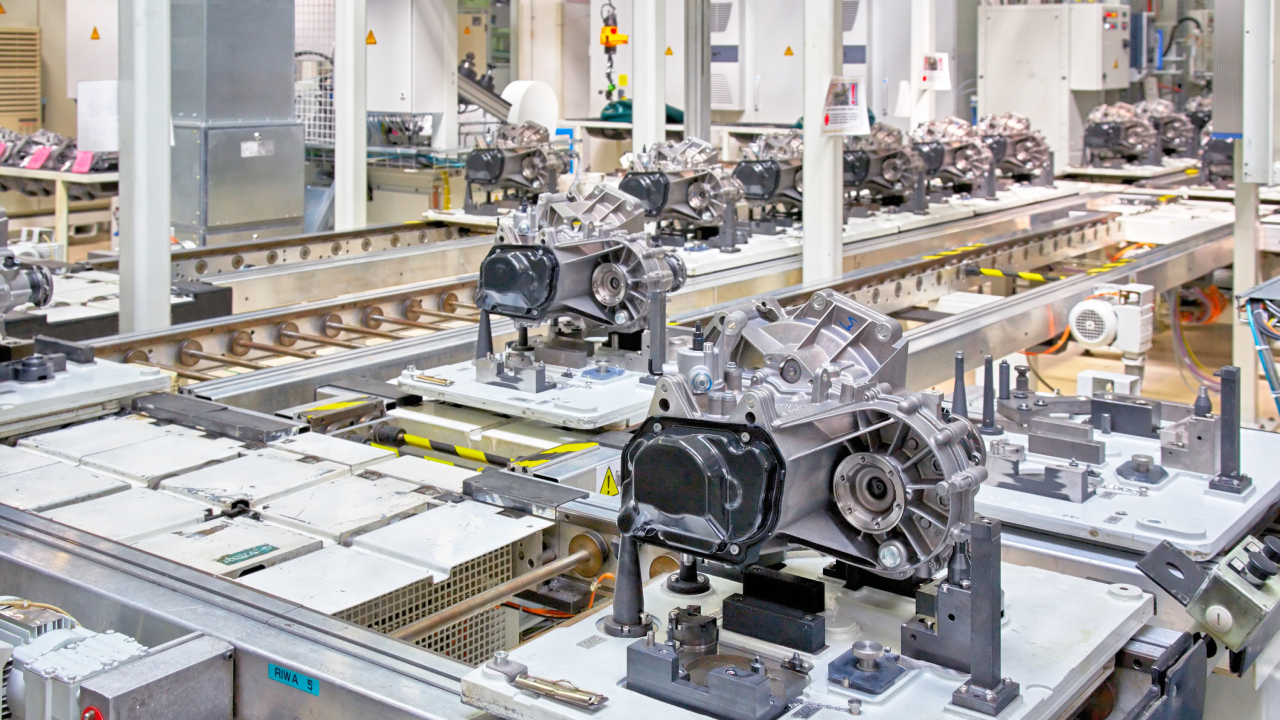

The Devastating Impact of Too Much WIP: How Excess Inventory Kills Manufacturing Flow

In manufacturing, WIP (Work in Progress or Work in Process) refers to partially finished goods that are at various stages of production but not yet completed. In accounting terms, WIP represents the value of raw materials, labor, and overhead that has been invested in unfinished product. Reducing WIP is a frequently cited goal for many

-

Finite Capacity Planning: The Key to Meeting Customer Expectations

Table of Contents In competitive markets, meeting customer commitments is critical. If resources like inventory, people, and equipment were always readily available, consistently delivering on time wouldn’t be such a challenge. The difficulty is that nearly all manufacturing operations have constraints. In this post, I will drill down into finite capacity planning, how it helps

-

Kaizen vs. Kaikaku

Kaizen vs. Kaikaku: 2 Approaches to Lean Manufacturing That Can Transform Your Factory The Lean Manufacturing world is littered with new terminology, and given the discipline’s origins, it’s not surprising that some of these words and phrases are Japanese. Being “fluent” with these words to the point that you can bring them up in

-

Why Data-Driven Manufacturing is Not Enough

Occasionally, someone will mix up DDM (Demand-Driven Manufacturing) with another DDM acronym in our industry: Data-Driven Manufacturing. There are similarities. For example, executing demand-driven principles relies heavily on data and shop floor visibility. However, it doesn’t stop there. In this post, we’ll take a look at Data-Driven Manufacturing and why it’s useful but not enough