Manufacturing productivity is a useful metric for measuring the health of manufacturing at a national or global level because it tells us something about whether our factories, in general, are working or sitting idle. But at the level of the individual factory, productivity as a performance metric can be problematic. Before we travel too far down that path, however, perhaps we should start by defining what we mean by manufacturing productivity.

What is Manufacturing Productivity?

The Business Dictionary defines productivity as a measure of the efficiency of a person, machine, factory, system, etc., in converting inputs into useful outputs. Productivity is computed by dividing average output per period by the total costs incurred or resources (capital, energy, material, personnel) consumed in that period.

In short , the MBAs are defining productivity as a measure of how efficiently you are using resources, not how effectively you use them.

, the MBAs are defining productivity as a measure of how efficiently you are using resources, not how effectively you use them.

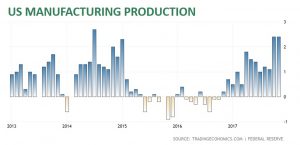

At a macro level, manufacturing productivity has been increasing for years. We’re producing more than ever. In large part, this reflects the level of automation in our factories. Automation helps us get more done, in less time, with fewer resources.

Productivity and Throughput Are Not the Same

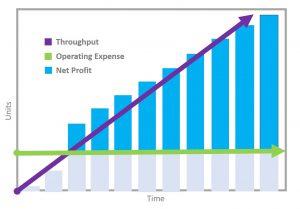

To be clear, we’re not saying productivity is a bad thing. Just that seeking to increase productivity for the sake of the metric can lead to unintended consequences such as increased inventory levels. A better metric, and one that those of you raised on Lean manufacturing principles are no-doubt familiar with, is throughput.

But once again, we need to avoid defining the word the way the rest of the world does.

A straight dictionary definition defines throughput as the amount of material or items passing through a system or process. Lean adds a bit of an accounting wrinkle to that definition by looking at throughput as the net profit made from selling a product or service.

If it’s been awhile since your last accounting class, look at it this way:

You have a machine that produces ten pieces an hour. By the standard definition, those pieces are throughput. However, under Lean principles, those pieces are not throughput until they are converted into revenue (a.k.a. “sold”). Demand-Driven Manufacturing incorporates Lean theory, with special emphasis on this idea of throughput.

Productivity: Use with Caution!

If you’re measuring your factory or individual resources (employees, work centers, etc.) based on the standard dictionary definition of productivity (or throughput), don’t be surprised if you wind up with inflated inventory levels, missed delivery dates, and long lead times.

There are better ways of measuring productivity that take net revenue into account. For example, one analyst firm recommends a productivity metric that measures profit per hour. Not bad. However, to drive continuous improvement, metrics need to serve two purposes:

- Provide actionable input

- Provide that input while there’s still time to have an impact

Profit per hour doesn’t serve either of these well. Knowing that your profit per hour is X doesn’t really tell you much about how to get it to X+1. The danger in this is that employees and managers may see a focus on profit per hour as a mandate to “work faster,” and as we all know, this is not the same thing as working smarter.

a focus on profit per hour as a mandate to “work faster,” and as we all know, this is not the same thing as working smarter.

The second problem with metrics like profit per hour is that they are lagging indicators, telling you only how you did in the past. They do nothing to predict future performance. Lagging indicators are how the executive team, the market, and investors look at performance, so it’s not a bad idea to monitor them. But on the shop floor, we also need metrics that will help us influence future performance.

There is one caveat I need to make about measuring productivity. If you’re measuring productivity of a constraint in a Demand-Driven Manufacturing environment, constraint productivity is a very useful metric. If you’re interested in learning more about this, we have a plethora of additional resources on our website regarding constraints management (Theory of Constraints).

If Not Manufacturing Productivity, Then What?

In our continuous improvement efforts, we need to leverage Pearson’s Law: That which is measured improves. That which is measured and reported improves exponentially. If we aren’t going to measure performance or productivity, at least not at the employee or non-constraint work center level, what are we going to measure?

Two metrics can be particularly useful at the work center level, especially in a Lean Manufacturing environment. These metrics support behaviors desired to drive flow and maximize throughput:

Schedule Adherence: Perform work in the order that maximizes global throughput. Schedule Adherence measures how effectively your employees work through orders in the queue. Are they sticking to the plan? Improved schedule adherence leads to better on-time delivery performance and decreased expediting.

Queue Turns: Maximize flow by working to turn queues as quickly as possible. In a typical manufacturing environment, 85-90% of cycle time is made up of the time materials spend in-queue, waiting to be processed. Queue turns measure how often the queue in front of a resource turns over in a given time period. More queue turns means less time waiting and lower cycle times.

Schedule Adherence and Queue Turns are metrics that represent what working effectively in a production environment is all about.

What to Use to Get the Most of Your Demand-Driven Changes

What to Use to Get the Most of Your Demand-Driven Changes