Blog

-

Thought Leadership: 4 Ways SyncKanban® eKanban Technology Drives Continuous Improvement

Every year, right-sizing inventory tops the list of strategic goals for many manufacturers. But right-sizing inventory is never a “once and done” initiative. Even in demand-driven manufacturing environments where replenishment is linked to demand, there is room for continuous improvement. This paper focuses on how you can use several features within SyncKanban® eKanban Software to

-

Fast Results Using TOC for Demand-Driven Manufacturing – Part Two

Manufacturers use constraints management first to gain the most demand-driven change Last time, we talked about focusing on enterprise improvements rather than local efficiencies using constraints management (TOC). We discussed that continuous improvement tools such as TOC, Lean and Six Sigma work like “sandpaper” on an organization’s processes, smoothing various stages of their demand-driven journey.

-

Turn Your Gemba Walk into a Power Walk

Gemba is a term that is increasingly familiar in the manufacturing world. Loosely translated from Japanese, it means “the place where the work is done.” The originators of the Gemba Walk – the practice of walking the shop floor to identify waste – knew that manufacturing process issues could not be identified or solved in

-

What Sandpaper Will You Use? – Part One

What to Use to Get the Most of Your Demand-Driven Changes Demand-driven manufacturing leaders are always refining their tools and tactics to ensure they’re spending their time wisely. This blog marks the first in a three-part series about using the tools of TOC, Six Sigma and Lean to help manufacturing leaders gain the most benefit

-

Getting Lean on Scrap

Getting Lean on Scrap eKanban focuses manufacturers on reducing inventory, lowering cycle times, and helps best practice operations reduce scrap as part of continuous improvement efforts…MORE

-

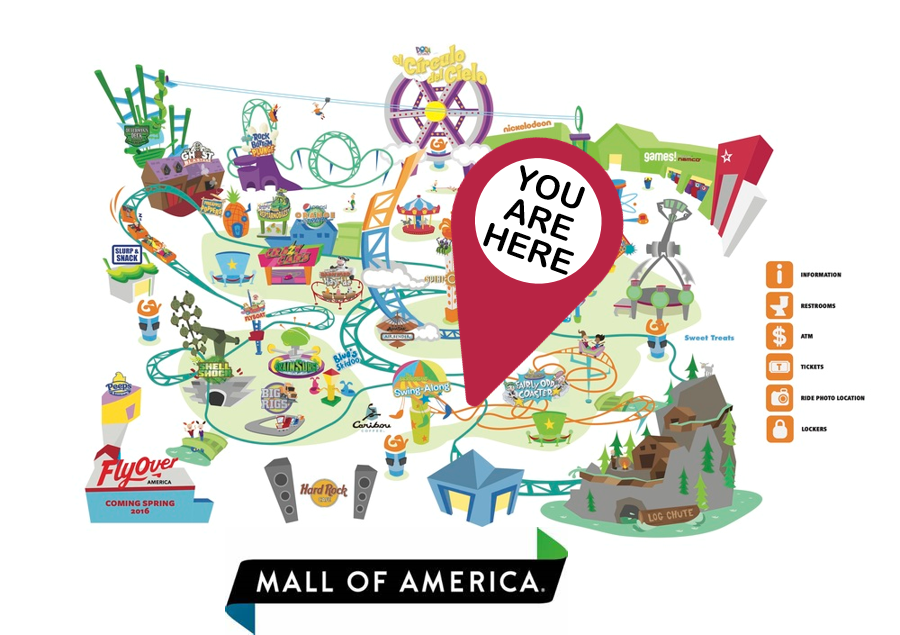

You are Here!

Where to Start Your Lean Journey There’s one sure-fire way to tell when someone has lived in Minneapolis long enough to be called a Minnesotan. No, it doesn’t involve rooting for the Vikings, though that helps. It’s when they can find their way around The Mall of America without a directory. Built in