- Focus on Metrics that Matter

- Gain Greater Workflow Control

- Achieve End-to-End Visibility

- Keep Complex Builds in Sync with Supply Allocation

- Be Fast and Future Ready

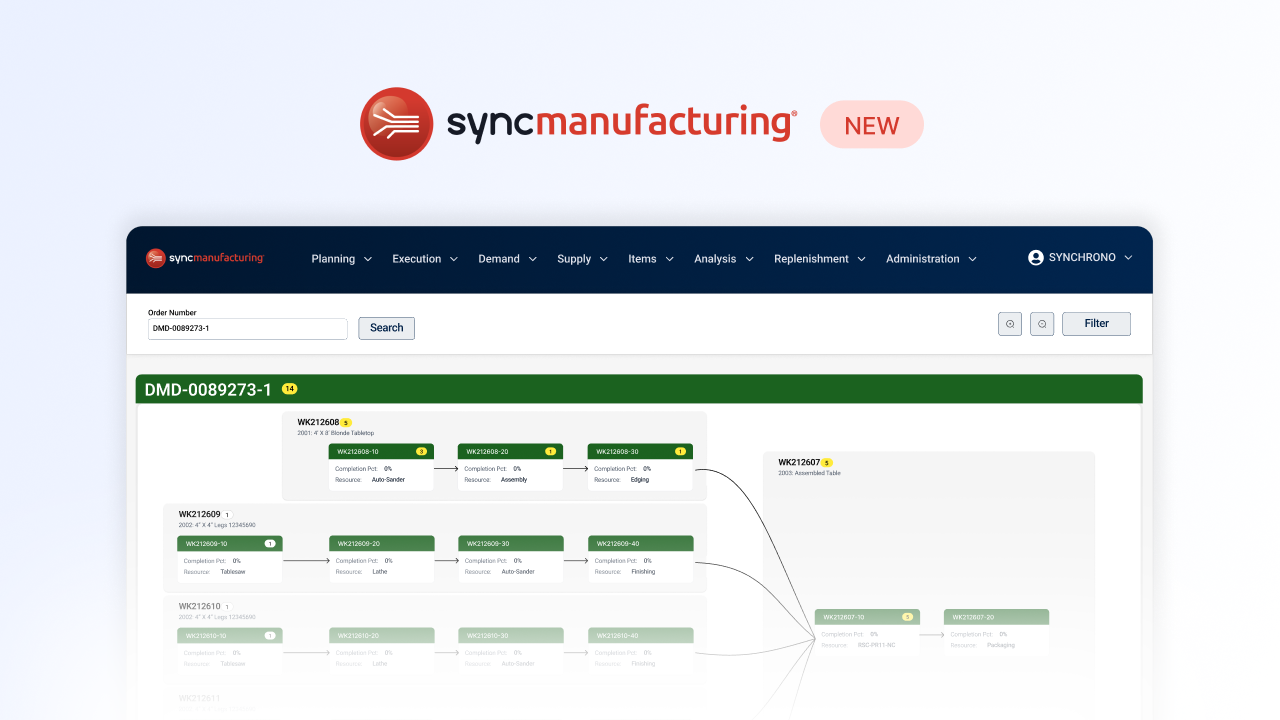

- See the New SyncManufacturing in Action

More Visibility, More Power, More Control for Even the Most Complex Manufacturing Environments

Synchrono® is excited to share what’s new in SyncManufacturing® Version 8, a release shaped by the real-world challenges and ideas of manufacturers like you. With improved operational visibility, smarter controls, streamlined production planning, a modernized technology platform, and several user-driven enhancements, Version 8 delivers a powerful, more intuitive experience across even the most complex manufacturing environments.

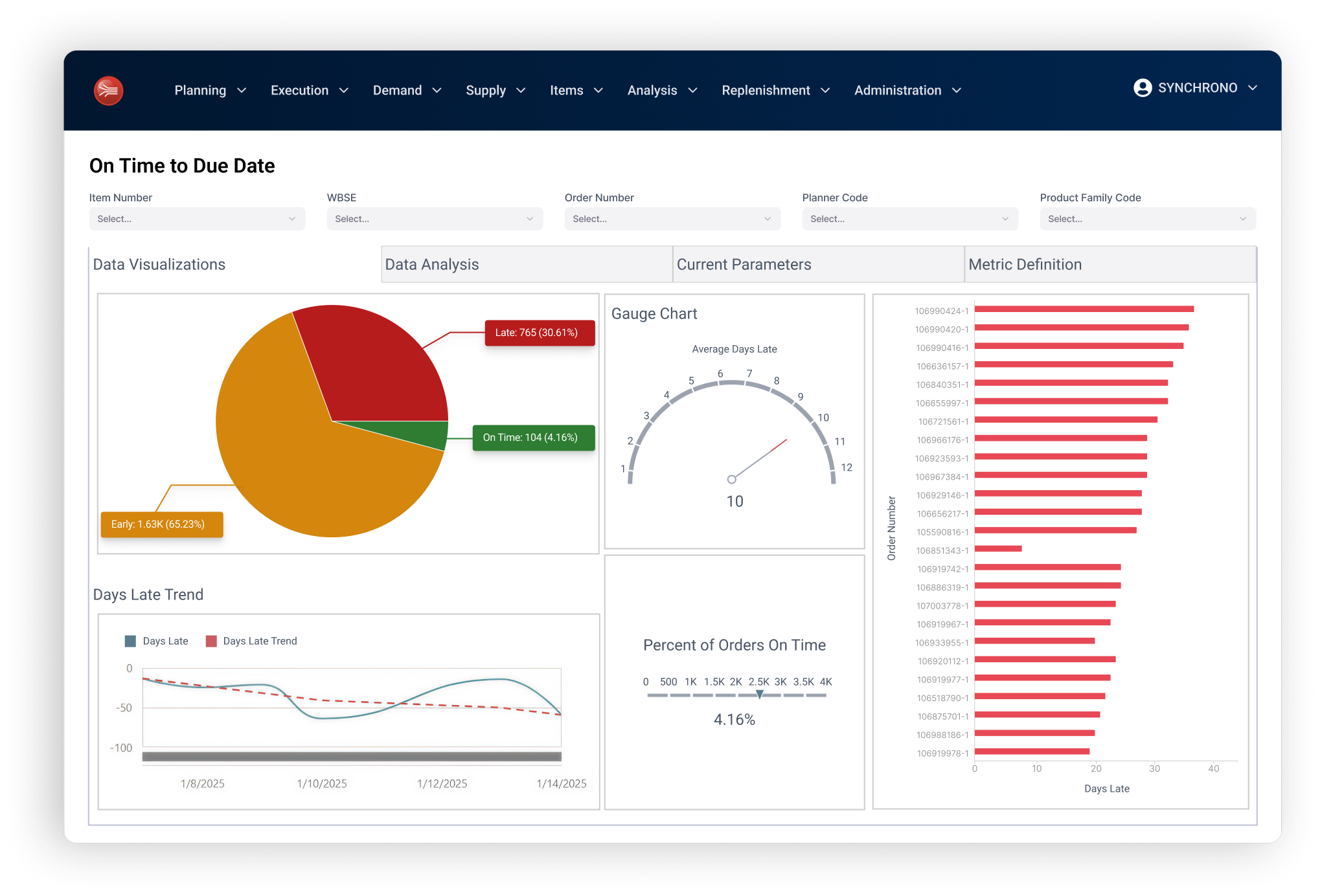

Focus on the Metrics that Matter

Version 8 introduces built-in Business Intelligence (BI) Dashboards that turn production data into actionable insights for continuous improvement on the shop floor. Five standard dashboards—Cycle Time Variance, Order Release Adherence, CONLOAD Adherence, On Time to Due Date, and Schedule Adherence—provide an at-a-glance view of how well your operations are performing against plan.

- Cycle Time Variance highlights whether demonstrated cycle times align with planned routings, making it easier to spot inaccurate cycle-time assessments.

- Order Release Adherence shows how closely execution follows system-generated release dates, a key driver of flow and schedule stability.

- CONLOAD™ Adherence focuses on constraint resources, comparing average released load hours to modeled maximum load to show when critical resources are consistently over- or under-released.

- On Time to Due Date segments orders into early, on-time, or late buckets, and can be viewed either as a forward-looking projection on open orders or a retrospective view of demonstrated performance.

- Schedule Adherence tracks how well actual production follows the planned schedule, making it easier to spot batching, cherry picking, and chronic variability that undermine flow and delivery performance.

These dashboards help teams understand not just what is happening, but why it is happening, and because they are built directly into SyncManufacturing, users no longer need to open a separate tool to view, export, or analyze this data.

Gain Greater Workflow Control

SyncManufacturing 8 significantly expands precedence management with new Ad Hoc Precedence, Operation Precedence, and Order Precedence capabilities that allow you to precisely control the sequence in which work is executed across production orders and operations.

Ad Hoc Precedence lets users create dependencies across two or more production orders so that a downstream action cannot begin until a defined upstream step is complete. The SyncManufacturing scheduling engine enforces those relationships throughout the plan.

Operation Precedence allows users to define detailed dependencies between operations across production orders, usually for process dependencies that are not defined within the standard bill of material. The dedicated Operation Precedence screen allows you to add, update, and delete precedence edges (i.e., the link that defines the dependency between two operations in the schedule) at the operation level, providing granular control for scenarios such as shared subassemblies, paired components or serialized assemblies where one operation on a production order must be completed before an operation on another production order may begin.

Order Precedence extends this control to the order level by allowing planners to create dependencies at a less granular level than operations. Users select the relevant production orders, and SyncManufacturing automatically establishes the precedence between the final operation of the first production order and the first operation(s) of the second production order, ensuring that schedules respect critical make-before-assemble or phase-gate relationships.

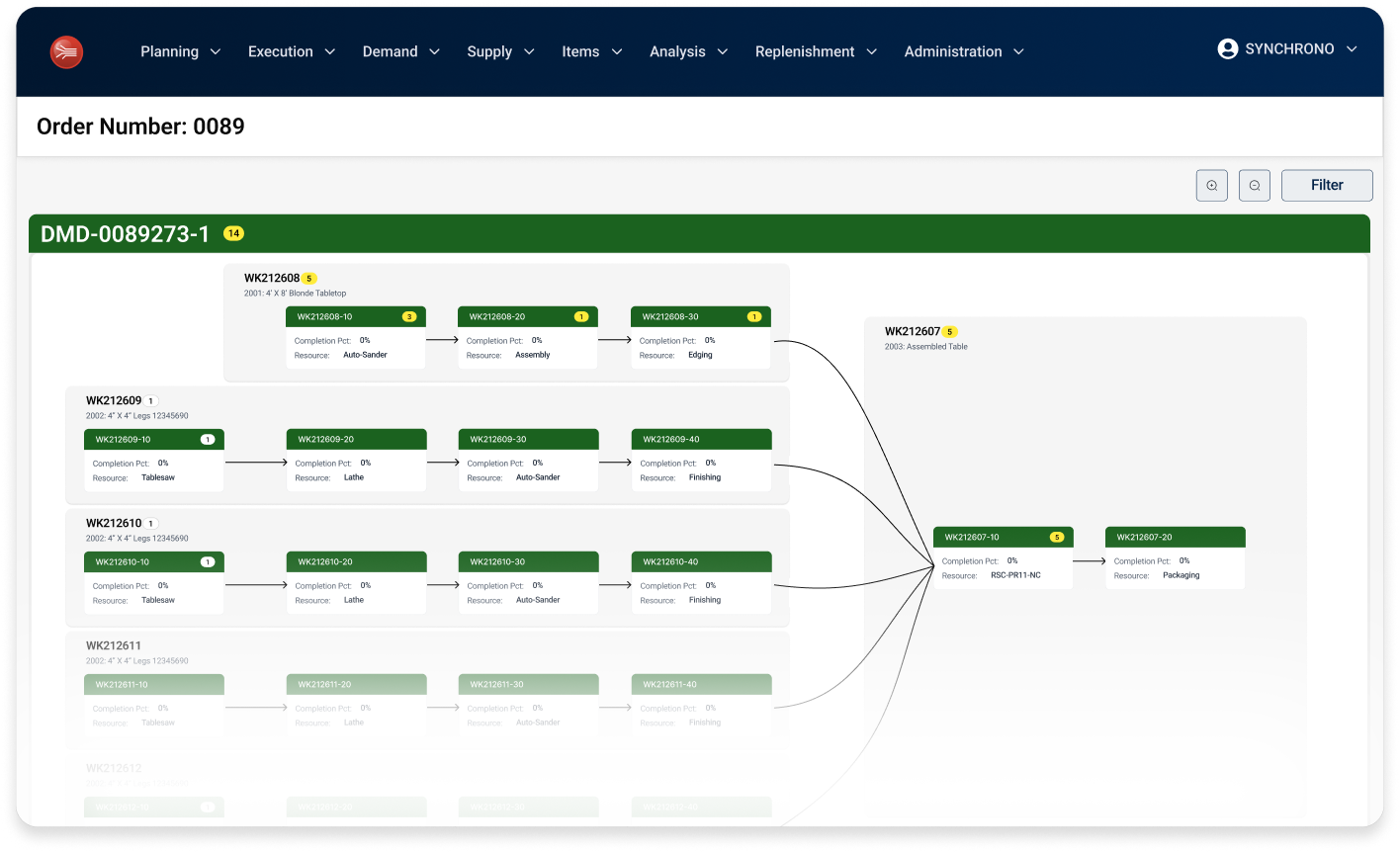

Achieve End-to-End Visibility

The Production Plan screen has been redesigned in SyncManufacturing Version 8 to present complex order structures, networks, and precedence relationships in a single, cohesive view. The updated interface now supports the latest modeling options—including networks, order, and operation precedence—so planners can see how every element of the plan connects and impacts downstream operations.

Multi-level orders can display rolled-up status along with related precedence edges, which is especially valuable in environments with multi-stage assemblies or nested routings. Information on inputs to each operation is accessible through a bottom drawer that opens on demand, giving users the detail they need on material availability and inputs without leaving the main plan view.

The broadened Network Order Lines capabilities further enhance end-to-end insight by making it easier to understand and manage which orders are tied to which network. From the Network Maintenance screen, the new Network Order Lines view shows existing order lines and lets users add or remove additional ones, tightening control over how complex project or network-based orders flow through the system.

Supply allocation and detailed sequencing logic benefit from underlying improvements in performance and data handling, including enhanced algorithms and fixes to support pegging in diverse environments. These changes help ensure that when planners evaluate capacity, material, and due dates, the system can respond more quickly and reliably, even under heavy data volumes.

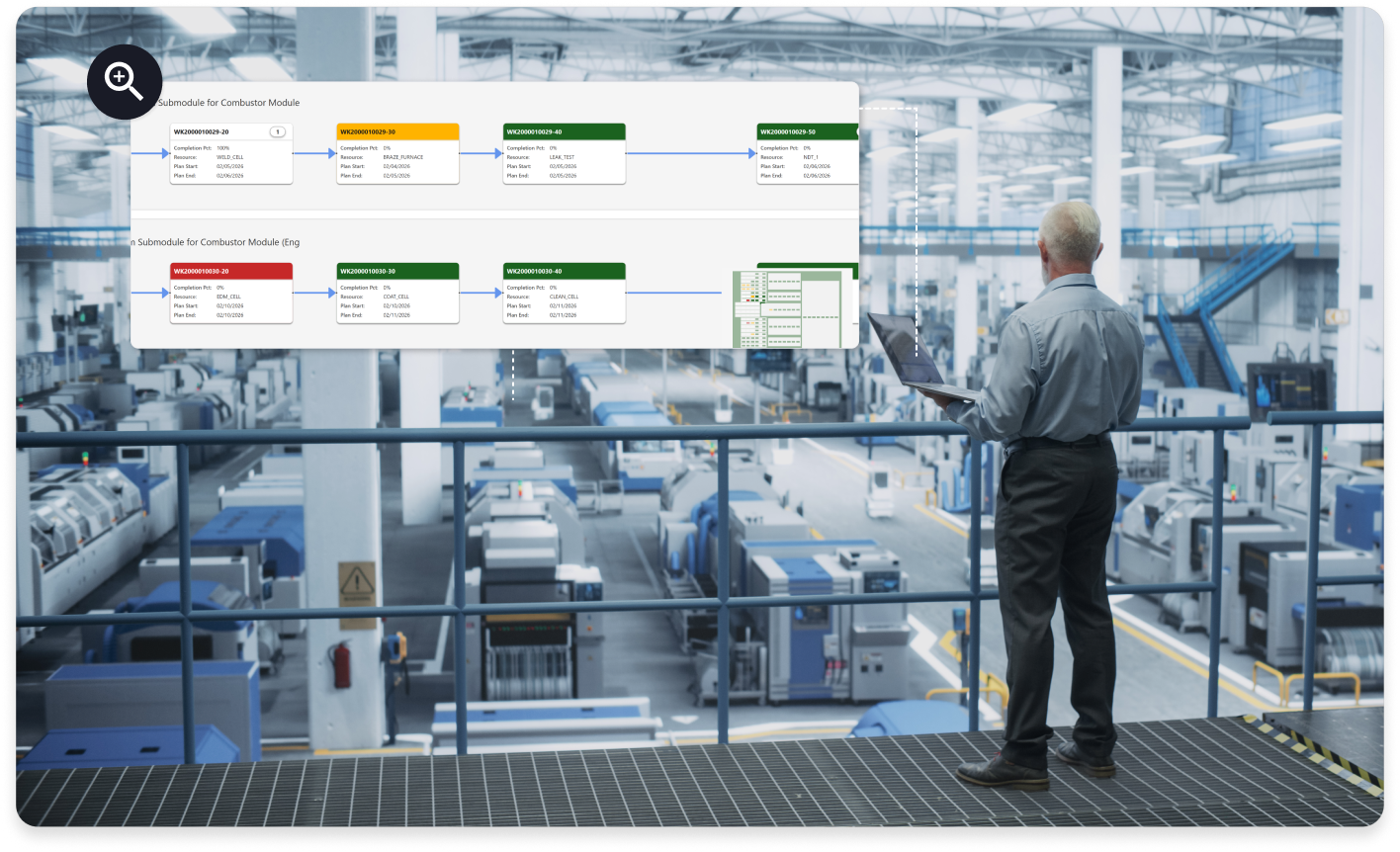

Keep Complex Builds in Sync with Supply Allocation

SyncManufacturing Version 8 introduces Supply Allocation, a new capability that keeps complex, multi-level builds synchronized by directly linking every supply order to the specific demand it serves across all BOM levels. Instead of treating each work order as an isolated record with manually maintained dates, Supply Allocation models the entire build as a single, flowing system so upstream and downstream operations move together.

With these direct linkages in place, every child order “knows” which parent order it supports and how its timing affects the overall build, allowing the scheduling engine to orchestrate the whole structure as one extended process. When conditions change—late material, shifting priorities, or capacity constraints—the impact on the entire order structure is visible in a single, coherent view, and dates are automatically recalculated from the true supply–demand relationships rather than ad hoc due-date resets.

The result is a more reliable and efficient operation: supply is tightly aligned with demand so parts always have a clear destination, orders are released to the floor only when they are truly buildable, and planners no longer spend hours stitching together pegging logic across multiple screens and spreadsheets. Organizations gain clearer insight into critical and late paths, reduce stalled work and WIP, and improve on-time delivery by spotting emerging delays early, making Supply Allocation a foundational capability for manufacturers managing deep, multi-level builds in volatile environments.

Be Fast & Future Ready

Under the hood, SyncManufacturing Version 8 delivers significant platform updates that position customers for long-term agility and performance, including upgraded screens for Calendar Maintenance, Group Maintenance, User Maintenance, and other key planning and administration pages.

By rebuilding these screens with new UI components, Version 8 provides a more responsive, fluid experience for planners working with complex order structures, calendars, and networks, with faster loading, smoother interactions, and layouts that adapt cleanly to different window sizes and devices so critical information is visible without excessive scrolling or refreshes. For IT and operations teams, the modern component-based architecture is easier to maintain and extend, enabling new visualization, filtering, and workflow features to be introduced more quickly as business needs evolve.

The new App Settings page consolidates configuration options and provides centralization that streamlines administration for system owners and implementation teams, reducing the time required to manage settings and improving consistency across environments.

Performance and stability enhancements appear throughout the application. CONLOAD™ has been optimized, improving performance for constrained-resource planning scenarios, and the Resource Load Report has been reworked to pre-summarize grouped data, align chart and grid values, and better support analysis of completed operations. Numerous refinements—ranging from grid sorting and scrollbar behavior to improved error messages—help deliver a smoother, more predictable experience for end users.

Key infrastructure components have also been refreshed, including an upgrade for Calendars functionality and new API endpoints to provide clearer status feedback for background jobs. Enhancements to login compatibility messages and new fields like compatible host in plan units ensure users are alerted if attempting to log into incompatible sites, increasing reliability and reducing support overhead.

See the New SyncManufacturing® in Action

SyncManufacturing Version 8 reflects our ongoing commitment to helping manufacturers orchestrate demand, capacity, and flow across increasingly complex operations. From BI Dashboards that spotlight true performance drivers, to advanced precedence management, redesigned production planning, and a faster, more future-ready platform, this release delivers meaningful value for planners, schedulers, supervisors, and executives alike.

To see how these capabilities can support your specific environment, Synchrono offers live demonstrations that walk through real-world scenarios using the new Version 8 features. Already a customer using SyncManufacturing? Reach out to your Synchrono Consultant to learn more about upgrading.

Three Ways Leaders Create Lean

Three Ways Leaders Create Lean