Most experts agree. The metrics you use to manage your manufacturing operations need to matter, and they need to be actionable. We concur. For a detailed review of the operational metrics we recommend in a demand-driven manufacturing environment, refer to our Metrics for Action Guide.

Conventional wisdom also says to keep the number of metrics you measure to a minimum. This advice is based on well-established research that shows that the human brain just can’t focus on more than five to seven things at a time. Trying to measure too many things at once has long been a recipe for never getting anything done.

Besides, many manufacturers are still calculating metrics by hand (or spreadsheet) from information that is gathered manually, often with considerable effort. By the time they get the information they’re looking for, it’s already obsolete. Measuring more than a select handful of metrics may not be realistic.

But, maybe it’s time to take another look at the way we think about metrics in manufacturing.

It’s time to let go of conventional wisdom.

Today’s technologies have solved the problem of outdated data. Metrics can be calculated in real-time and refreshed almost instantly. Tools are even available to gather data from the most antiquated of ERP systems, standardize it, and combine it with data from the increasingly extensive sources enabling the Internet of Things (IoT) that exist in almost every manufacturing environment.

Technology also gives you the power to create a set of role-specific metrics that are accessible through dashboards from any device. A plant floor manager can see the metrics that matter at the plant level in Peoria using a tablet, while the COO can see the metrics that matter across the entire operations using a smartphone while waiting for a flight in Singapore.

Modern technology collects and analyzes data from multiple sources, providing real-time visibility to metrics you can quickly take action on to improve.

Modern technology collects and analyzes data from multiple sources, providing real-time visibility to metrics you can quickly take action on to improve.

Of course, technology hasn’t yet changed our ability to concentrate on more than half a dozen things at once. (Regardless of how much we may try.) However, with the right applications, we don’t need to.

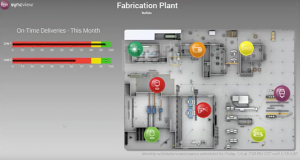

For example, plant floor managers no longer need to comb through every metric and compare it to acceptable norms or historical data to identify problem areas. Nor do they need to walk the plant floor hoping to spot possible problems, which savvy factory workers are often adept at covering up. With the right software, dashboards can be as sophisticated as a visual representation of the shop floor with color-coded indicators showing problem areas. The plant manager can measure metrics like queue turns at every single workstation in their domain, but they only need to pay attention to those workstations where queue turns are outside of the acceptable range.

Plant level view with indicators showing the status of key metrics at each workstation.

We’re not suggesting you go wild with managing metrics. Remember, they still need to matter, and in demand-driven manufacturing, there are generally fewer metrics that do. However, we are saying that if there is a metric that matters to you, why be held back by conventional wisdom from the 20th century?

To learn more about how technology can help you manage – and visualize – the metrics that matter, join us online for our on-demand webinar Visualizing Metrics in the Factory of the Future.