Have you ever had one of those moments when a thought hits you that is so obvious that you wonder why it never occurred to you before? I just decided that there couldn’t be a technology less aptly named than Enterprise Resource Planning, more commonly known as ERP.

Before I go into why, let me lay the groundwork so we’re all using the same terminology.

What is ERP?

From a manufacturer’s perspective, ERP was born with the addition of MRPII to the core financial functionality already found in existing systems. Pretty much all of these early systems provided modules for GL, AR, and AP. (Sometimes called “GLAPAR” in industry jargon.) Many of the early ERP solutions provided some procurement functionality as well as sales orders, though not many offered manufacturing-oriented functionality like the ability to configure products on the fly.

Sometime in the 80s, ERP vendors realized if they wanted to target the manufacturing sector, they needed to provide tools to help manufacturers deal with what is arguably their biggest issue: inventory. That’s when Material Requirements Planning (MRP) – a concept that had been around since the 50s – was codified in software form.

There is a belief that manufacturers are slow to adopt technology. I think it’s more that tec hnology is slow to adopt manufacturing. Historically, ERP vendors have focused on manufacturing last, and many never quite get it right.

hnology is slow to adopt manufacturing. Historically, ERP vendors have focused on manufacturing last, and many never quite get it right.

And that leads me back to my original premise: ERP is an oxymoron.

Garbage In/Garbage Out

As Trey Jordan recently wrote in his post Going Lean: Should You Replace Your ERP System? (insert link), ERP systems are great at collecting financial transactions from all over the enterprise. The E in ERP is just fine. My problem is with Resource and Planning.

In this post, I’m just going to look at inventory, since many ERP systems don’t even try to manage capacity. If you want to look at this from the capacity perspective, you might enjoy our white paper: The Next Generation of Planning and Scheduling Solutions.

The core resource planning tool in ERP systems is, of course, MRP. Put simply, MRP looks at future material requirements and works backward using inputs such as current inventory levels, order lead time, and so on to create time-based requirements for raw materials and components.

In theory, that makes perfect sense. If I want to make 100 widgets by the end of the month and it takes me two weeks to do it, I need to make sure I have the materials available by mid-month in order to reach my goal. If some of the materials required are subassemblies built in-house, then the system issues production orders so they will be available when needed as well.

The problem lies not in the algorithms, but in the inputs. Or to use a technology axiom that’s been around even longer than MRP: Garbage In/Garbage Out.

Where does the order for 100 widgets come from? The quick answer is the production schedule, but what are the inputs into that? In push-based manufacturing environments, the primary input into the production schedule is the sales forecast.

Therein lies the problem.

Sales forecasts are always inaccurate; the only question is by how much. I just Googled “sales forecast accuracy” and got 2 million hits, most of them having to do with why sales forecasts are always wrong. I skimmed a few of the results to see how accurate forecasts are on average, and the answer seems to be around 75%.

However, many of these articles and posts looked at forecasts from the perspective of the sales team: Did sales hit the numbers? A 100% accurate forecast from the perspective of the VP of Sales can still be wildly inaccurate from the perspective of production if the products sold were different than those forecasted.

Wisely, many manufacturers have learned not to trust the forecasts generated by sales. They hold weekly S&OP meetings to look sales leaders in the eye and review what’s in the forecast so they can adjust their production schedules based on what seems realistic and doable. These meetings can get tense. And, as much as the participants would like to apply proven processes to their S&OP meetings, they don’t do much to fix the core problem: Everyone is still guessing.

Manufacturing Demands a Different Approach

Maybe I should cut the ERP vendors a break. It’s not that their systems are coded poorly; it’s that they start with the wrong premise. That is, they were developed for push-based manufacturing, a generally accepted practice even though MRP has never been proven to provide the sustainable performance improvements manufacturers need.

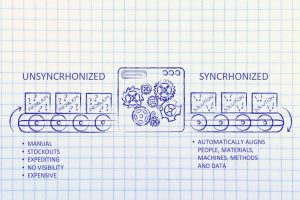

The opposite of push-manufacturing is pull, where resources (including capacity) are synchronized to customer demand. Pull is a core element of manufacturing principles such as Lean Manufacturing and JIT Inventory Management, so many readers are probably familiar with it. We often used pull-manufacturing or pull-replenishment synonymously with Demand-Driven Manufacturing, though our software Platform also applies other core principles of Lean such as Theory of Constraints.

If you’re tired of dealing with an Enterprise Resource Planning application that does nothing to help you plan resources effectively, I encourage you to investigate Demand-Driven Manufacturing. Our website is filled with white papers, articles, on-demand product demonstrations, and case studies that can help you learn more. If you’re brand new to the concept, check out our YouTube video: What is Demand-Driven Manufacturing?