What to Use to Get the Most of Your Demand-Driven Changes

Demand-driven manufacturing leaders are always refining their tools and tactics to ensure they’re spending their time wisely. This blog marks the first in a three-part series about using the tools of TOC, Six Sigma and Lean to help manufacturing leaders gain the most benefit from their demand-driven transformation.

Three in One

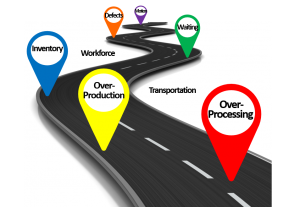

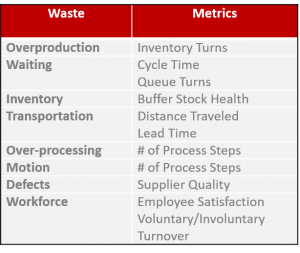

TOC, Lean, and Six-Sigma should all be part of the continuous improvement (CI) journey at your company – and knowing which tools are right for the job will help you realize your CI goals faster. And even though these three methodologies are not the end all, be all of continuous improvement, they offer proven frameworks and tool sets that are very effective at improving organizations.

During this discussion, I want to explain how the methodologies of TOC, Lean, and Six-Sigma work like sandpaper. TOC is the coarse, Lean is the medium, and Six-Sigma is the fine-grit sandpaper. The company is the board –or piece of wood in a particular state of roughness – and you have to know which paper to use, based on the state of the board. At Synchrono, we use all of these methodologies together—leveraging the right tools at the right time —and apply them strategically in our customers’ demand-driven transformation.

TOC to Start

I have never seen a more effective approach when you are just starting out than TOC. The methodology is all about understanding the entirety of the system and based on that, knowing where the leverage points are in the organization that, if affected, will bring about a rapid change to the entire system. It recognizes the interconnectedness and cause and effect of organizations, their people, resources, processes, and most important, policies.

When you first start a continuous improvement journey, the opportunities for improvement are great. They are everywhere within the organization and once the workers in the system have approval and the tools to change the system; they will do so with great effort. However, if we want to get the most out of these efforts, we need to focus these improvement efforts on the constraints/ leverage points of the organization to yield global results, not just localized effects. Said differently, we need to focus on the areas inhibiting enterprise performance, and I have not seen a more effective approach at doing this – and doing this quickly – than the TOC methodology.

Next time, I’ll talk about how to use TOC to pinpoint the changes necessary to get the most out of your continuous improvement efforts. Then, I’ll address the role of kaizen events and drill down into how Six Sigma – the finest grit of sandpaper – can refine your process change and ensure that each moving part works harmoniously together. Like many jobs, having the right tools makes all the difference in the world. The right methodologies, along with ongoing refinement, will steer your demand-driven environment towards embodying the best in form and function.

This is part one of a three-part series. Here are the links to the entire series.

- Part 1, What Sandpaper Will You Use?

- Part 2, Fast Results Using TOC for Demand-Driven Manufacturing

- Coming soon

-John Maher

John’s passion for demand-driven manufacturing is equal to his interest in how this method improves the lives of employees within these environments. “I’m here to help, not to judge” comments John whose posts reflect why demand-driven matters and are based on his experience working in manufacturing environments and expertise in ERP, MRP, APS, supply chain, manufacturing planning and scheduling systems and constraints management.