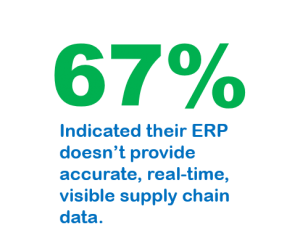

Most manufacturers have, at one time or another, deployed an “ERP add-on.” These are the bits and pieces of functionality sold through third parties that round out the capabilities of an ERP system. Common ERP add-ons can include core functionality like Advanced Planning and Scheduling (APS) and Supply Chain Planning (SCP), but for major ERP systems, there are dozens if not hundreds of add-ons available.

Because add-ons are such a familiar term to manufacturers, we’re often asked if this is what we mean when we talk about deploying a layered technology approach to Demand-Driven Manufacturing. Not exactly, but before I go into the differences, let me bring everyone up to speed by sharing Gartner’s viewpoint on the layered approach so we can put the differences in context.

Gartner’s 5 Stages of Supply Chain Maturity

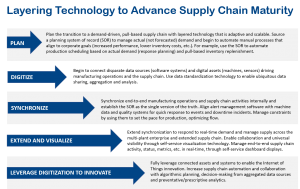

In a recent report, Supply Chain Maturity Assessment for the Demand-Driven Supply Chain, Gartner defines 5 Stages of Supply Chain Maturity. On one end of the spectrum, Stage 1 is a reactive environment where the manufacturer primarily uses manual processes (for example, spreadsheets for scheduling). On the other end, Stage 5, is a fully integrated enterprise, leveraging algorithms and predictive analytics for continuous improvement across the supply chain.

Progression through each of these stages does not require replacing an inadequate ERP system with one that is more fully functional. Instead, Gartner advocates layering on technology to progress to ever-higher levels of supply chain maturity. The layered approach allows manufacturers to apply maturity-enabling technology at a targeted and affordable pace. It also drives a faster ROI than a traditional ERP implementation. Here’s an example:

3 Ways the Layered Approach is Different

So, how is what Gartner is recommending different from the add-ons ERP vendors have been offering for decades? We see three major differences. There is some overlap with what some add-on vendors offer, but when taken together, the layered approach is a major step-forward for organizations looking for a fast, affordable way to leverage technology to improve operational performance.

Philosophy before function. Add-on applications tend to focus on addressing capability weaknesses within an ERP system. For example, an APS application may offer the ability to do finite capacity planning. That’s good, but finite capacity planning is a point-solution to a specific problem.

Layering technology provides a broader, more business objective-oriented approach to systems than simply adding on an application to plug a hole. For example, our Demand-Driven Manufacturing layers help manufacturers achieve a leaner, more agile environment by implementing philosophies like Lean, Six Sigma and constraints management.

Source agnostic; big picture. Add-on vendors are getting better at working with disparate ERP systems, but there’s often still an integration challenge to be addressed before the add-on can start providing the promised benefits. If there are multiple sources, e.g. financials, CRM, home-grown point solutions, the project can get very complex. Many questions need to be answered such as: What format does the data need to be in? How do we ensure the data gathered is current? How do we combine the data from multiple sources?

Source agnostic; big picture. Add-on vendors are getting better at working with disparate ERP systems, but there’s often still an integration challenge to be addressed before the add-on can start providing the promised benefits. If there are multiple sources, e.g. financials, CRM, home-grown point solutions, the project can get very complex. Many questions need to be answered such as: What format does the data need to be in? How do we ensure the data gathered is current? How do we combine the data from multiple sources?

Furthermore, because the add-on is focused on a specific challenge, it only provides one aspect of the big picture. Any given role in a manufacturing organization needs analysis from multiple systems. Requiring that the user access reports and dashboards across systems to get what they need wastes time and resources.

Our approach involves layering technology that can connect to any data source – even raw data from the machines on your shop floor – and standardize the data so that it can be aggregated, analyzed and visualized across the enterprise in real-time. Users don’t have to access multiple point solutions or machines to get the information they need.

Supply chain ready. Layered technologies are web- and cloud-based, where a shared pool of resources are available on-demand. The subtle but important difference is that our approach means that the technology layers can be used across supply chain partners for end-to-end supply chain visibility and management.

Supply chain ready. Layered technologies are web- and cloud-based, where a shared pool of resources are available on-demand. The subtle but important difference is that our approach means that the technology layers can be used across supply chain partners for end-to-end supply chain visibility and management.

Related Resources:

White Paper: The Demand-Driven Supply Chain

Article: The Changing Role of ERP in Manufacturing